In modern manufacturing, the application range of aluminum materials is becoming increasingly widespread, and aluminum diamond plate, as a common aluminum alloy sheet, has been widely used in industrial and construction fields. This article will introduce the characteristics, processing technology, and application scenarios of aluminum diamond plates, hoping to provide you with valuable information.

What is Aluminum Diamond Plate?

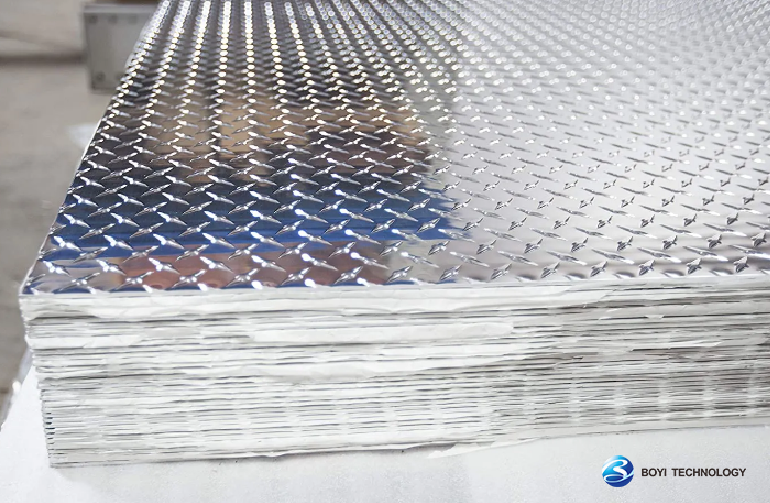

Aluminum diamond plate, also known as aluminum tread plate, aluminum checker plate, or simply diamond plate, is a type of aluminum sheet or plate with a raised, diamond-shaped pattern on one surface. This distinctive pattern is formed by raised lines or ribs arranged in a regular diamond grid pattern.

Aluminum diamond plate is typically made from aluminum alloy, commonly 3003, 5052 ro 8020 aluminum alloys, which offer good corrosion resistance, strength, and weldability. The raised diamond pattern not only enhances the appearance but also provides functional benefits such as improved traction and durability. It is often chosen for its combination of aesthetic appeal and practicality.

This type of plate is widely used in various industries such as transportation (for truck beds, trailers, and vehicle flooring), architecture and construction (for stairs, ramps, wall panels, and decorative purposes), marine applications (for boat decks and hulls), as well as in manufacturing and machinery (for flooring, toolboxes, and equipment surfaces).

Video Description

Characteristics of Aluminum Diamond Plate

Aluminum diamond plate is named after its special surface pattern, which is not only beautiful but also has anti slip and wear-resistant properties, making it highly favored in many fields. Compared to ordinary aluminum plates, aluminum diamond plates have the following characteristics:

1. Slip-resistant and Wear-resistant

The special diamond pattern of aluminum diamond plate not only gives it an attractive appearance but also provides excellent slip resistance. This design enables it to maintain good traction in wet or greasy environments, significantly reducing the risk of slipping. Moreover, this pattern increases its surface wear resistance, prolonging its lifespan, making it particularly suitable for high-traffic and high-pressure areas.

2. Excellent Corrosion Resistance

Aluminum diamond plate undergoes special treatment, often utilizing processes such as anodizing, to form a dense oxide film, thereby enhancing its corrosion resistance. This oxide film not only effectively resists oxidation and corrosion but also protects the surface of the aluminum plate from environmental erosion, extending its lifespan.

3. High Strength and Lightweight

Compared to regular aluminum sheets, aluminum diamond plate has higher strength, able to withstand certain loads and pressures. However, compared to steel materials, aluminum diamond plate has a lower density, making it lighter and easier to transport, install, and handle. This lightweight characteristic not only reduces transportation costs but also alleviates structural loads, especially suitable for applications requiring light weight yet requiring a certain level of strength.

4. Excellent Processing Performance

Aluminum materials have excellent ductility and processing properties, allowing aluminum diamond plate to be cut, bent, stamped, and processed using various techniques to meet various complex shapes and size requirements. Particularly through CNC machining, high-precision processing can be achieved, ensuring product quality and dimensional consistency.

The processing technology of aluminum diamond plate covers various techniques, from simple cutting to complex surface treatments, each of which plays a crucial role in the quality and performance of the final product.

Put your parts into production today

Processing Technology of Aluminum Diamond Plate

The processing technology of aluminum diamond plate covers various techniques, from simple cutting to complex surface treatments, each of which plays a crucial role in the quality and performance of the final product.

1.CNC Machining

CNC (Computer Numerical Control) machining is a high-precision processing method that utilizes computer-controlled CNC machine tools to perform cutting, engraving, drilling, and other machining operations on workpieces. For materials like aluminum diamond plate, CNC machining offers precise, efficient, and flexible machining solutions.

Workflow of CNC machining:

- Design Drawing:

Firstly, use CAD (Computer-Aided Design) software to draw the part drawings of the aluminum diamond plate. Designers determine the dimensions, shapes, and features of the cuts based on customer requirements and product specifications. - CAM Programming:

Next, use CAM (Computer-Aided Manufacturing) software to convert the CAD-drawn drawings into CNC programming code. CAM software generates machining paths, cutting trajectories, and machining instructions based on the design drawings so that CNC machine tools can perform machining operations according to the predetermined paths. - Program Loading:

Load the CNC programming code generated by CAM into the control system of the CNC machine tool. These codes contain machining process parameters, tool trajectories, machining depths, etc., allowing the control system to achieve precise machining of the aluminum diamond plate according to these instructions. - Machining Operation:

CNC machine tools perform machining operations on the aluminum diamond plate according to the predetermined machining paths and instructions. This may involve cutting, drilling, milling, etc., with specific operations determined by the product’s design and requirements. - Quality Inspection:

After machining is completed, inspect the machined parts for quality. Measurement tools are typically used to check whether the machining dimensions, shape accuracy, etc., meet the requirements, ensuring that the product quality meets standards.

Advantages of CNC machining:

High Precision: CNC machine tools can perform precise machining according to predetermined paths and instructions, ensuring the accuracy of cutting dimensions and shapes.

Strong Flexibility: CAM software can generate different machining programs according to requirements, adapting to various complex shapes and design requirements.

High Production Efficiency: The automated machining process improves production efficiency, reduces manual operation and processing time, and enhances production efficiency and product quality.

Wide Applicability: CNC machining is suitable for processing various materials and complex shapes, meeting customers’ personalized requirements.

More: Check out our CNC machining services

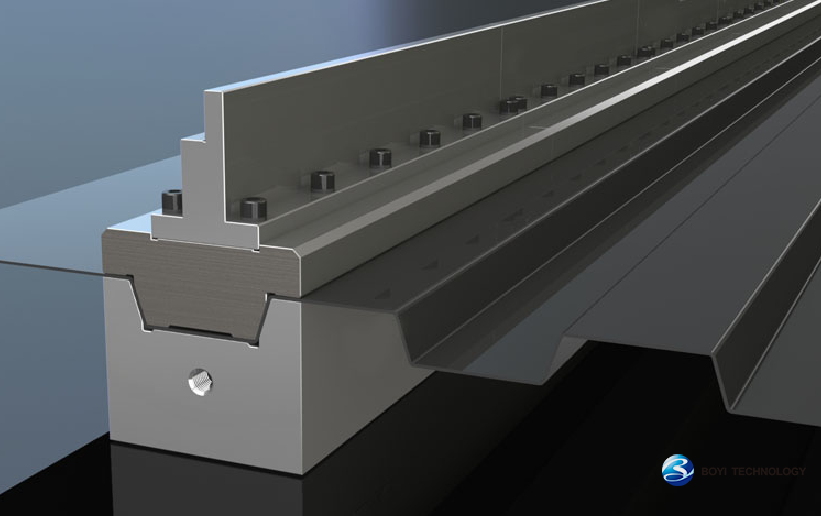

2.Bending Forming

Bending forming is a commonly used processing method used to bend aluminum diamond plates into the desired shapes and sizes according to design requirements. This processing method is typically carried out on dedicated bending machines, which precisely control the movements to achieve the bending and forming of aluminum plates.

Workflow of Bending Forming:

- Design Planning:

Before bending forming, detailed design planning is necessary. Based on the product’s design and technical requirements, parameters such as the required bending angles, bending positions, and dimensions and shapes after bending are determined. - Setting up the Bending Machine:

Place the aluminum diamond plate on the worktable of the bending machine and set parameters such as the movement trajectory, bending angle, and bending position of the bending machine according to the design plan. This usually requires operation and adjustment based on the control system of the bending machine. - Performing Bending:

Start the bending machine and bend the aluminum diamond plate along the predetermined bending trajectory. During the bending process, it is essential to ensure the stability and positioning of the aluminum plate, as well as the accuracy of the bending angle and position to guarantee the quality and precision of the final product. - Adjustment and Correction:

During the bending process, adjustments and corrections may be necessary based on actual conditions to ensure that the bent product meets the design requirements. This may involve fine-tuning the bending angle and adjusting the bending position, among other operations. - Quality Inspection:

After bending, inspect the formed parts for quality. Check whether the bending angles, dimensional accuracy, surface quality, etc., meet the design requirements to ensure the product’s quality meets the standards.

Advantages of Bending Forming:

- Strong Flexibility: Bending forming can meet various processing requirements for different shapes and sizes, making it flexible for the production of various components and parts.

- High Precision: By precisely controlling the movement trajectory and parameters of the bending machine, high-precision bending and forming can be achieved to ensure the quality and precision of the product.

- High Production Efficiency: Bending forming is an efficient processing method capable of rapidly and batch producing the required products, thus improving production efficiency.

- Lower Cost: Compared to other processing methods, the equipment and process costs of bending forming are relatively lower, making it suitable for medium and small-batch production and customization requirements.

3.Surface Finishing

Surface finishing is a process carried out to enhance the corrosion resistance and decorative properties of aluminum diamond plate. Common surface finishing methods include anodizing, coating, and sandblasting.

Anodizing:

Anodizing is a surface treatment method that forms an oxide film on the surface of aluminum through an electrolytic process. In the anodizing process, aluminum plates act as the anode and undergo the action of specific electrolytes and currents, forming a dense oxide film on the surface. This oxide film not only enhances the corrosion resistance and hardness of the aluminum plate but also has certain insulation and decorative properties. Aluminum plates after anodizing can maintain their original aluminum texture, or they can be dyed as needed to achieve customized colors.

Spraying:

Spraying is a surface treatment method that evenly applies coatings to the surface of aluminum plates. Common coatings include polyester coatings, epoxy coatings, polyurethane coatings, etc. Spraying can coat aluminum plates with various colors and patterns, increasing their decorative and aesthetic appeal. Additionally, sprayed coatings can provide some protection, preventing aluminum plates from being eroded or damaged by the external environment. The spraying process is suitable for aluminum plates of various complex shapes and sizes, meeting customers’ personalized requirements.

Sandblasting:

Sandblasting is a surface treatment method that uses high-pressure air to spray sand particles onto the surface of aluminum plates, creating a sandblasted effect. Sandblasting can remove the oxide layer and dirt from the surface of aluminum plates, making the surface smoother and more uniform, while also enhancing its texture and tactile sensation. The surface of aluminum plates after sandblasting has a certain roughness, making it less slippery and exhibiting good anti-slip performance. Sandblasting treatment can adjust the particle size and intensity of sandblasting according to customer requirements to achieve different surface effects and requirements.

More: Check out our surface finishing services

Common Application of Aluminum Diamond Plates

Aluminum diamond plates have a wide range of applications in various fields, and their characteristics and advantages make them an ideal choice for many industries.

1.Transportation:

In the transportation sector, aluminum diamond plate is commonly used for truck and trailer floors and side panels. Its anti-slip and wear-resistant characteristics enhance driving safety by preventing cargo from sliding or personnel from slipping in wet or slippery conditions.

Reference case: https://www.eng-tips.com/viewthread.cfm?qid=423196

2.Architectural Decoration:

In architectural decoration, aluminum diamond plate is widely used as exterior walls, ceilings, staircase treads, and other decorative materials. Not only is it aesthetically pleasing and durable, but it also provides anti-slip functionality, suitable for various buildings, including public places, industrial plants, etc.

3.Shipbuilding:

In shipbuilding, aluminum diamond plate is often used for ship decks, cabins, and other parts. Due to its lightweight and corrosion resistance, it reduces the weight of ships, improves fuel efficiency, and thus its application in shipbuilding is increasingly widespread.

4.Furniture Manufacturing:

In furniture manufacturing, aluminum diamond plate is commonly used for outdoor furniture, garden tables, and chairs, among other products. Its weather resistance and aesthetic appeal make it suitable for harsh outdoor environments, while its anti-slip feature enhances safety during use.

5.Industrial Applications:

Apart from the aforementioned sectors, aluminum diamond plate is extensively used in industrial applications such as platforms, steps, and machinery enclosures. Its corrosion resistance, wear resistance, and lightweight properties make it an ideal choice for many industrial applications.

Conclusion

Aluminum diamond plate, as a high-quality material, not only performs well in CNC machining, but also has broad application prospects in various industries. As a professional CNC machining service provider, BOYI is committed to providing customers with high-quality and efficient machining services. If you have any processing needs or inquiries, please feel free to contact us at any time, and we will be happy to provide you with services.

Put your parts into production today

FAQ

According to industry standards, the strength of aluminum diamond plate primarily depends on its thickness and the design of the diamond pattern. Generally, common thicknesses of aluminum diamond plate range from 1/16 inch to 1/4 inch, with bending strengths typically falling between 10,000 and 30,000 psi. However, the strength of aluminum diamond plate is also influenced by the specific alloy composition, so exact data may vary.

Diamond plate can be expensive due to the precision machining required to create its distinct pattern, the relatively high cost of aluminum compared to other metals, and its durability and corrosion resistance, which make it a preferred choice for various applications. Industry data suggests that aluminum diamond plate can cost anywhere from $50 to $150 per sheet, depending on factors such as thickness, size, and finish.

Aluminum diamond plate can be cut using various tools depending on the thickness and precision required. Common tools include handheld shears, tin snips, circular saws with carbide-tipped blades, jigsaws with metal-cutting blades, and CNC cutting machines. The choice of tool depends on factors such as thickness, complexity of cuts, and desired precision.