Vacuum Casting Services

Boyi can supply any quantity of plastic parts, from small batch, high mix prototypes to large-scale production.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Home » Vacuum Casting

What is Vacuum Casting?

Vacuum casting (also known as silicone molding, urethane casting or polyurethane casting) is a manufacturing technique that uses vacuum to suck liquid casting materials (usually resin) into molds to form parts or products. It is the perfect solution for rapid prototyping and small low-volume manufacturing, suitable for manufacturing 20-500 sets of various plastic products. Compared to traditional injection molding processes, vacuum casting typically has lower costs, higher efficiency, and can greatly shorten product production cycles.

Boyi Vacuum Casting Capabilities

The following table summarizes the standard tolerances for parts produced by certified Boyi manufacturing partners. If you need stricter tolerance standards, please contact [email protected]

|

Feature

|

Description

|

|---|---|

|

Maximum Part Dimensions

|

1000 mm×500 mm×500 mm

39.4 in.×19.7 in.×19.7 in. |

|

Minimum Wall Thickness

|

±1 mm

± 0.04 in. |

|

Quantities

|

10 copies per mold

|

|

Accuracy

|

± 0.1 mm

± 0.004 in. |

|

Surface quality

|

Color and texture can be customized

|

|

Lead time

|

3 business days

|

Vacuum Casting Materials

You can choose different types of vacuum casting (urethane casting) materials based on project requirements and part usage. The following are several common vacuum casting materials:

|

Material Name

|

Shore Hardness

|

Colors

|

Applications

|

|---|---|---|---|

|

ABS-Like

|

Shore D 78-82

|

All colors; precise pantone color matching available

|

General purpose, product enclosures

|

|

Acrylic-Like

|

Shore D 87

|

Clear

|

Light pipes, see-through applications

|

|

Opaque Elastomer

|

Shore A 20, 30, 40, 50, 60, 70, 80, 90

|

All colors; precise pantone color matching available

|

Wearables, gaskets, overmolds

|

|

Polypropylene-Like

|

Shore D 65-75

|

Black or natural only

|

Enclosures, food containers, medical applications, toys

|

|

Polycarbonate-Like

|

Shore D 82-86

|

Clear and various colors

|

Light diffusers, signs, skylights, visors

|

|

Waterclear Elastomer

|

Shore A 30, 40, 50, 60, 70, 80

|

Clear

|

Wearables, gaskets, overmolds

|

|

PMMA

|

Shore D 90-99

|

RAL/Pantone colors

|

Lighting, signal display, partition material

|

|

Polystyrene

|

Shore D 85-90

|

Pantone colors

|

Displays, disposable items, packaging

|

Boyi can also purchase custom materials according to requirements.

Vacuum Casting Surface Finish Options

The following finishes can help you meet the specific appearance, texture, or functional requirements of vacuum cast parts. And ensure that the final parts meet the required specifications and standards.

High-Gloss

Semi-Gloss

Matte/Frosted

Textured Finish

Custom

From Prototype to Production

Vacuum casting(urethane casting) creates high-quality prototypes and small batch production parts solutions for different applications. We help you achieve your manufacturing goals.

Concept stage

Samples used to create display models or proof of concept

Early prototyping stage

Create prototypes to test the adaptability and functionality of parts

Late prototyping stage

Economically and efficiently produce 100 EVT units for testing and validation

Low-volume production

Solution for customized or Low-volume production needs (20-500 pieces)

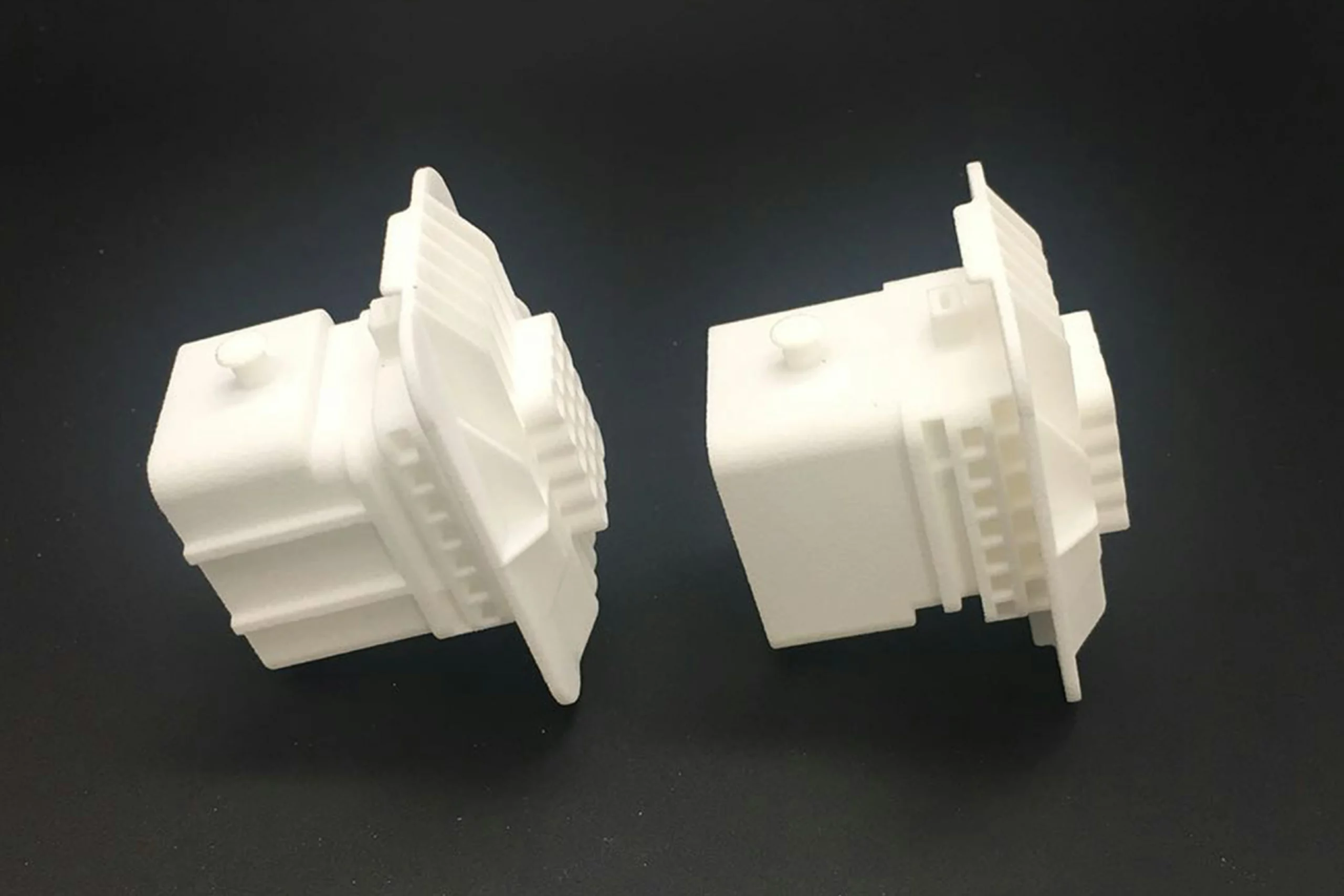

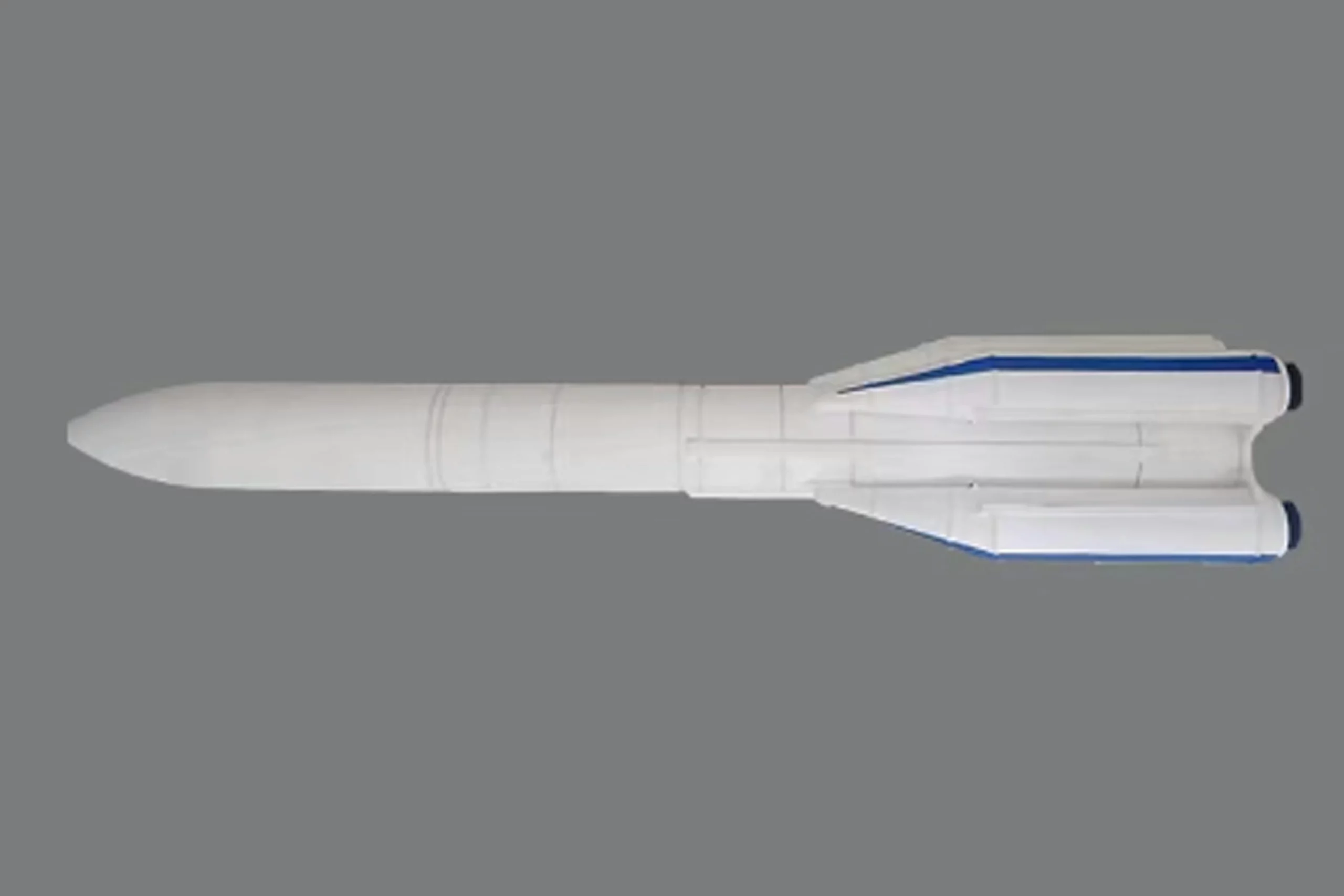

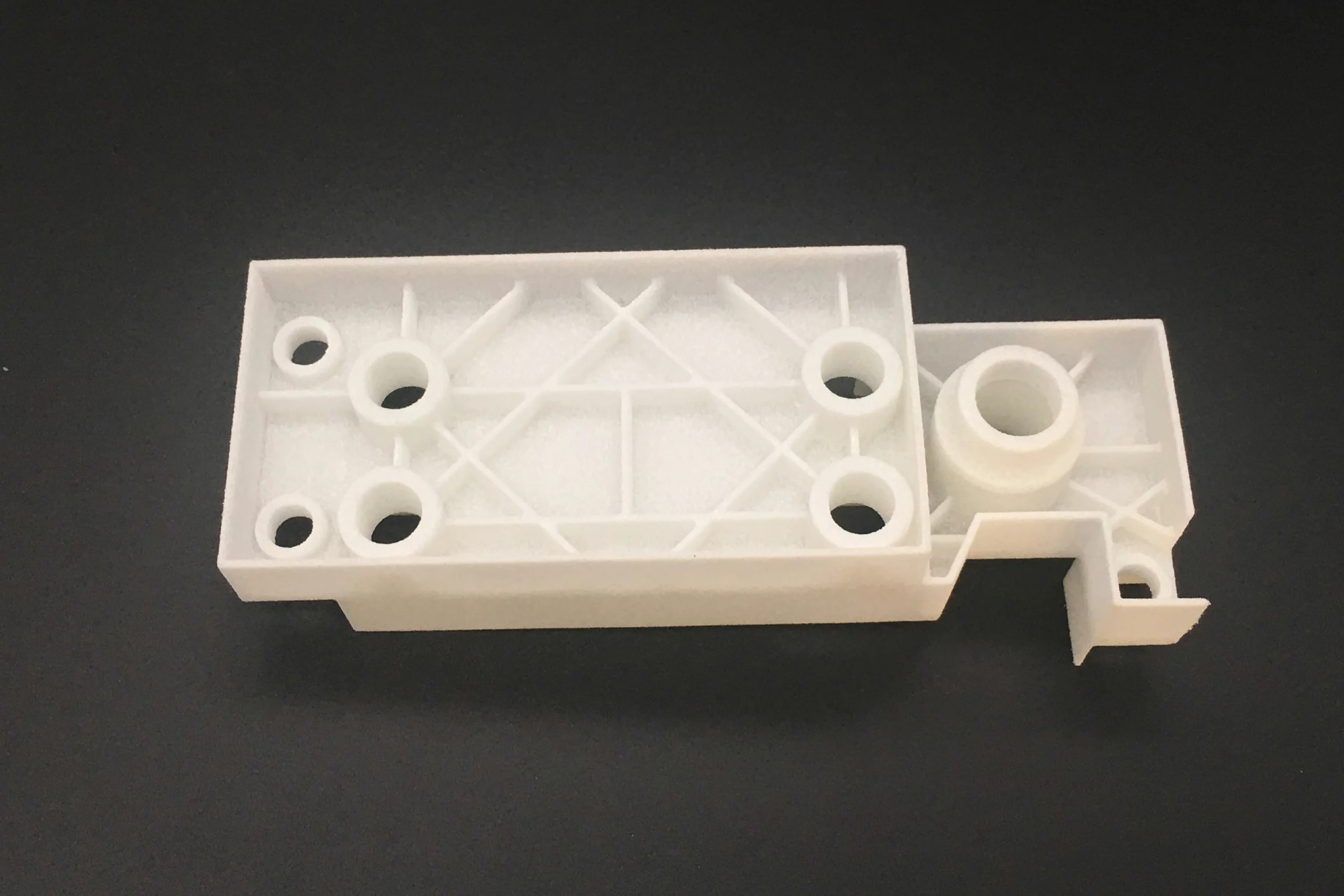

Gallery of Vacuum Casting Parts

Boyi can deliver up to 20 parts in 7 days or less, depending on part specifications and quantity.

Technical Overview: Vacuum Casting

About the Vacuum Casting Process

Vacuum Casting is a rapid prototyping process used to make high-quality plastic parts or products.

Vacuum casting production consists of three main steps:

1. Build a master pattern using 3D printing or CNC machining

2. Build the mold by pouring platinum silicone around master

3. Pour liquid polyurethane resin into mold, create polyurethane casting under vacuum

Advantages of Vacuum Casting

Compared to injection molding or 3D printing, vacuum casting can produce high-quality prototypes or small batch production of rigid, flexible, transparent, colored or rubber plastic parts, without the high cost and delivery time of requiring upfront investment to process mold steel or aluminum molds. This helps validate your design ideas before making significant investments to expand manufacturing scale.

What is the difference between vacuum casting and traditional casting?

Vacuum casting is different from traditional casting in terms of technology. It is carried out in a vacuum environment, which can reduce the presence of oxygen and other impurities, effectively reducing defects such as pores and inclusions. This makes the castings more uniform, with higher density and more reliable quality.

About Vacuum Casting FAQ

The production cycle varies depending on project complexity and quantity. Generally speaking, our Vacuum casting service can complete production within 3 days and ensure high-quality finished product delivery.

The materials we provide include but are not limited to ABS, polyurethane, silicone, etc. If you require specific customized materials, please contact [email protected] .

A vacuum casting mold can typically produce approximately 10 to 30 parts. When designing molds, we will try our best to consider improving their service life and efficiency to ensure the production of high-quality parts.