High Volume Production Services

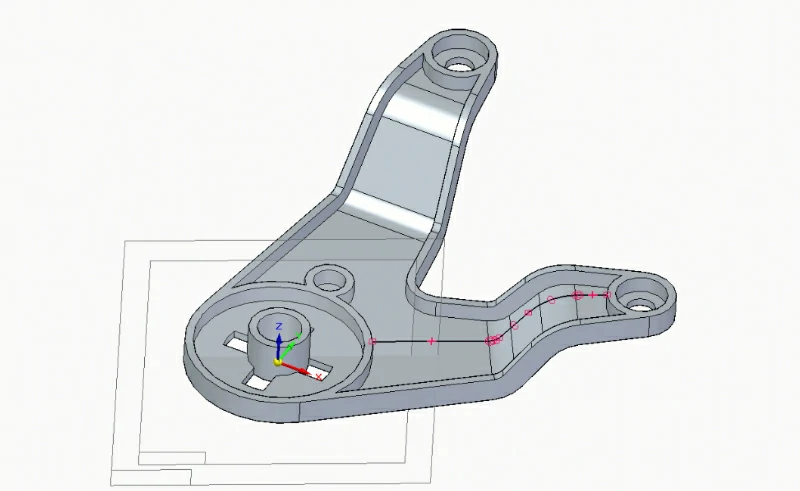

When ready for full-scale production, look no further than our high volume services. we can create precise and complex metal and plastics parts in large numbers quickly.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Home » High Volume Production

What is High Volume Production?

High volume production is a manufacturing method that involves producing large quantities of identical parts or products at once. For products with large-scale market demand, such as electronic products and automotive components, high volume production can produce a large number of consistent products in a short period of time, thereby meeting the market’s demand for large-scale supply.

High Volume Production Capabilities Comparison Table

|

Final Production Process

|

Single Project Production Capacity

|

Fast Delivery Time

|

Standard Delivery Time

|

|---|---|---|---|

|

CNC Machining

|

100000+

|

Minimum 3 working days

|

Minimum 5 working days

|

|

Injection Moulding

|

50000+

|

||

|

3D Printing

|

10000+

|

||

|

Sheet Metal Fabrication

|

10000+

|

||

|

Die Casting

|

50000+

|

||

|

Aluminium Extrusion

|

10000+

|

How BoYi utilizes high volume production

High volume production is generally beneficial for both manufacturers and consumers. To meet customer demands, we have streamlined the ordering and manufacturing processes. If you are interested in our bulk high volume production services, please feel free to contact us for more information. We can work with your existing blueprints or assist in creating them through our 3D CAD services. Once the design is in place, our experienced technical team will collaborate with each customer to identify the optimal container manufacturing methods.

What About Products with High Volume but Small Variety?

For products with a large quantity but limited variety, our company provides multiple manufacturing processes to meet different needs. A common method is to use low-volume injection molding to efficiently produce large quantities of products by injecting molten plastic into the mold.

This method ensures fast production speed, but it should be noted that the setup cost may be relatively high. If the budget is limited, this may need to be carefully considered. In the initial stage, we can focus on low-volume manufacturing, and then flexibly adjust production strategies according to market demand, gradually transitioning to mixed production of large and small batches.

Another option suitable for high volume but with limited variety of products is low-volume manufacturing, which uses CNC machining technology to manufacture products. Compared to low-volume injection molding, this method is more cost-effective. Our professional team is able to accurately process products that meet customer requirements through advanced CNC technology.

Still not sure which is right for you?Contact Now [email protected] Provide you with a solution and quote.

About High Volume Production FAQs

The production time depends on product complexity, order volume, and the movement of the production line. We will provide a detailed production schedule at the time of contract signing.

In high volume production, maximizing production efficiency, reducing production costs, and better meeting market demand can be achieved by producing a large number of identical products at once.

High volume production is suitable for multiple industries, especially in areas with high demand for products such as electronics, automotive manufacturing, consumer goods, and industrial products.