Custom Die Casting Services

Provide high-quality on-demand custom die cast parts. Get a quote in as little as 1 hour. The typical tolerance accuracy for aluminum, zinc, and magnesium is +/- 0.1mm.We can also customize tolerances.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Home » Die Casting

Die Casting Types Available from Boyi

By utilizing the latest die-casting machines and technologies, we provide high-quality custom die casting parts for various industries. Our products focus on two leading die casting technologies: hot chamber casting and cold chamber casting. Aluminum, zinc, and magnesium alloys can be selected for die casting using suitable processes.

Hot Chamber Die Casting

Hot chamber die casting, also known as “gooseneck” or “hot” casting, has a faster production speed because the metal is always in a molten state and does not require each cycle of heating. Very suitable for low melting point metals such as zinc, copper, and magnesium.

Cold Chamber Die Casting

Cold chamber die casting, also known as cold casting, involves pouring molten metal into the mold cavity instead of external heating to reduce machine corrosion. Very suitable for high melting point metals such as aluminum and copper.

Die Casting Alloy Material

When using die casting to produce parts, there are many different metal materials to choose from.You can find out more about the main types of die casting materials we offer in the following sections.

|

|

Available Varieties

|

|---|---|

|

Aluminium Alloy

|

A360, A390, A413, ADC-1,46500, A380, Al-Si8Cu3, 46100, ADC12, A383, Al-Si11Cu3

|

|

Zinc Alloy

|

Zamak-2, Zamak-3, Zamak-5, Zamak-7, ZA-8, ZA-12, ZA-27

|

|

Magnesium Alloy

|

AZ91D, AM60B, AS41B

|

If you have specific material requirements. Please contact [email protected]

Advantages of Die Casting Services with Boyi

Our team of experts will work closely with you throughout the process and provide advice and options to give you the best turnaround solution while working to meet your unique needs.

01

Serial Production

Very suitable for continuous production of large quantities of identical or similar die cast parts starting from 100 parts in a short period of time, improving production efficiency and cost-effectiveness.

02

Rapid Turnaround

We provide fast mold manufacturing services for your die-casting parts: fast molds can be delivered in a minimum of 7 working days, and production molds can be completed in a maximum of 15 days.

03

Strict Quality Control

Our process has passed ISO 9001:2015 certification. Ensure that the production of die cast parts at each stage of the manufacturing process meets the highest quality standards.View our quality control standards

04

Endless Options

We offer a wide range of material choices and surface finishing options for your die casting parts, covering millions of possible combinations to meet your personalized die-casting part order needs.

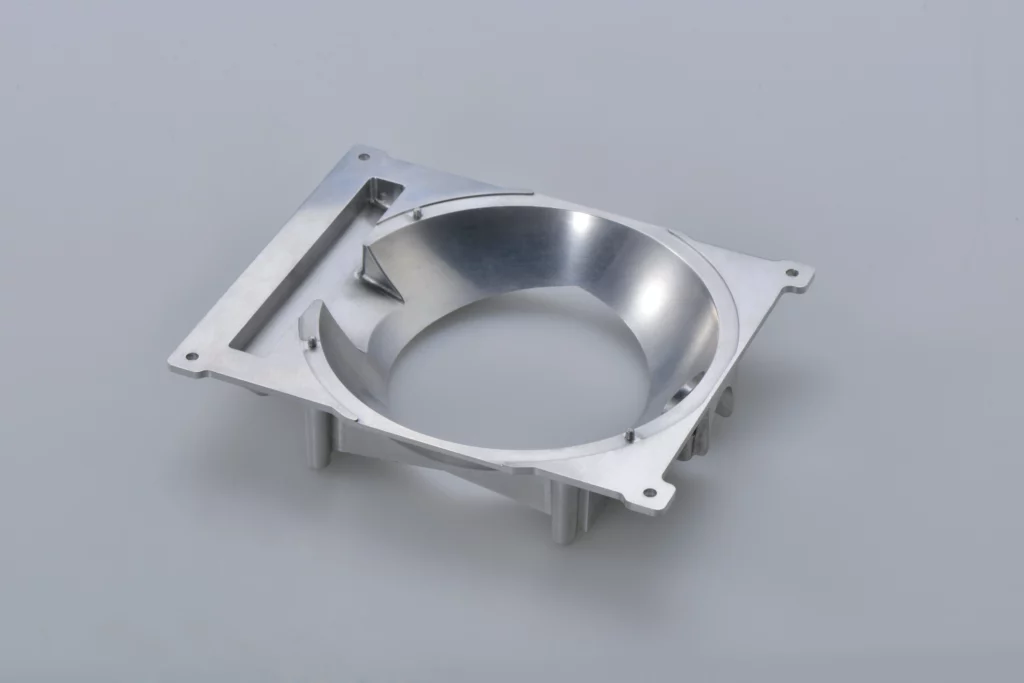

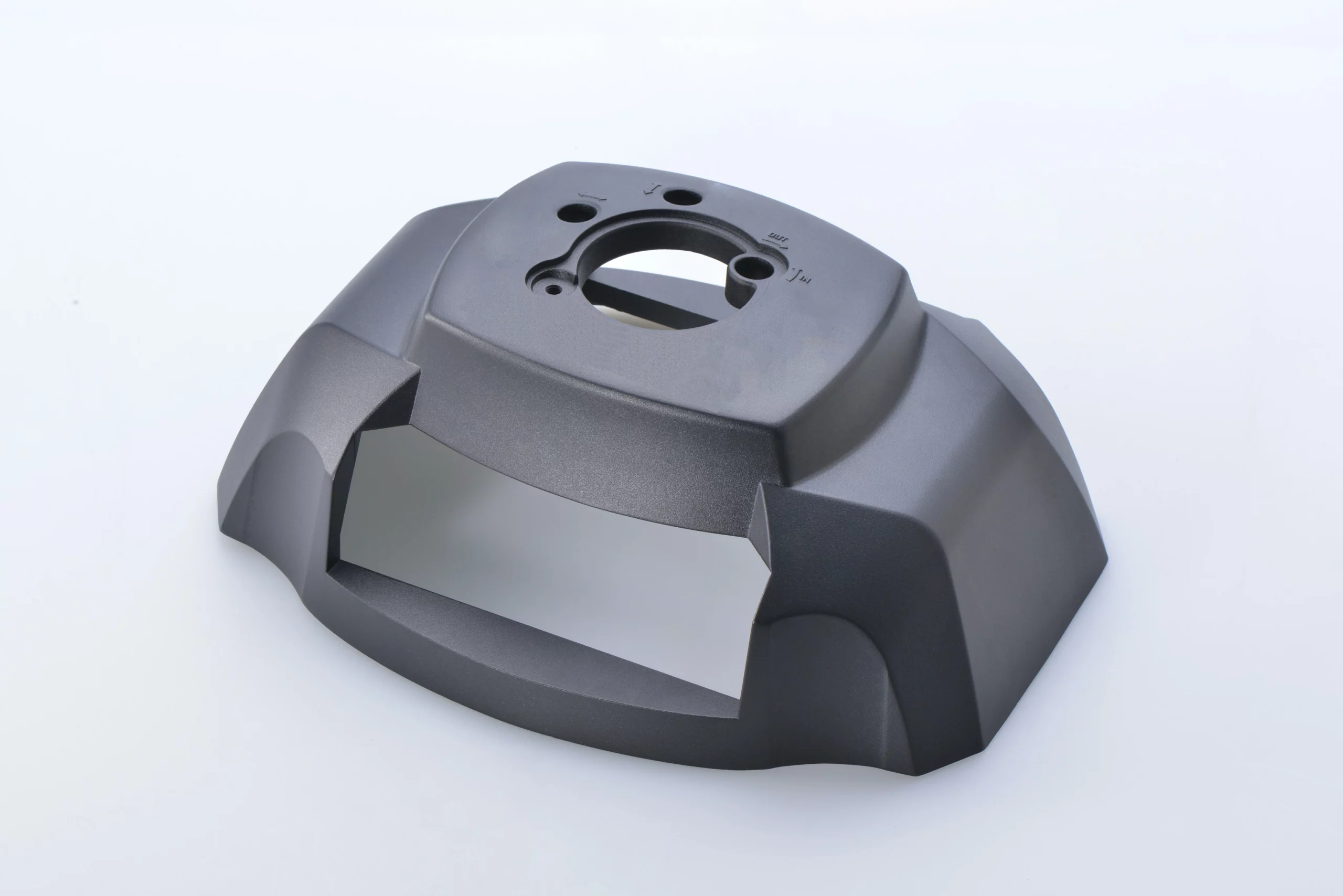

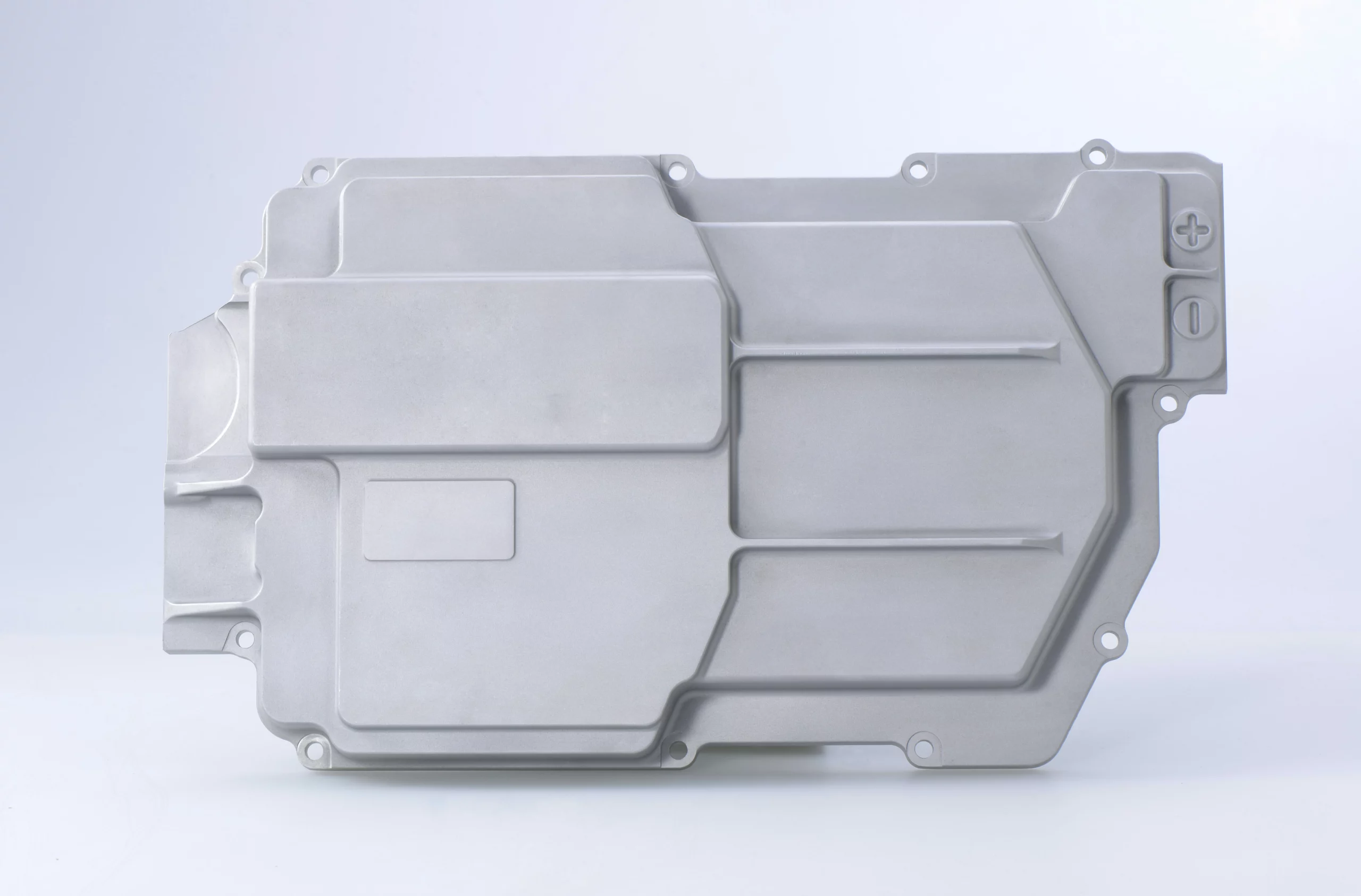

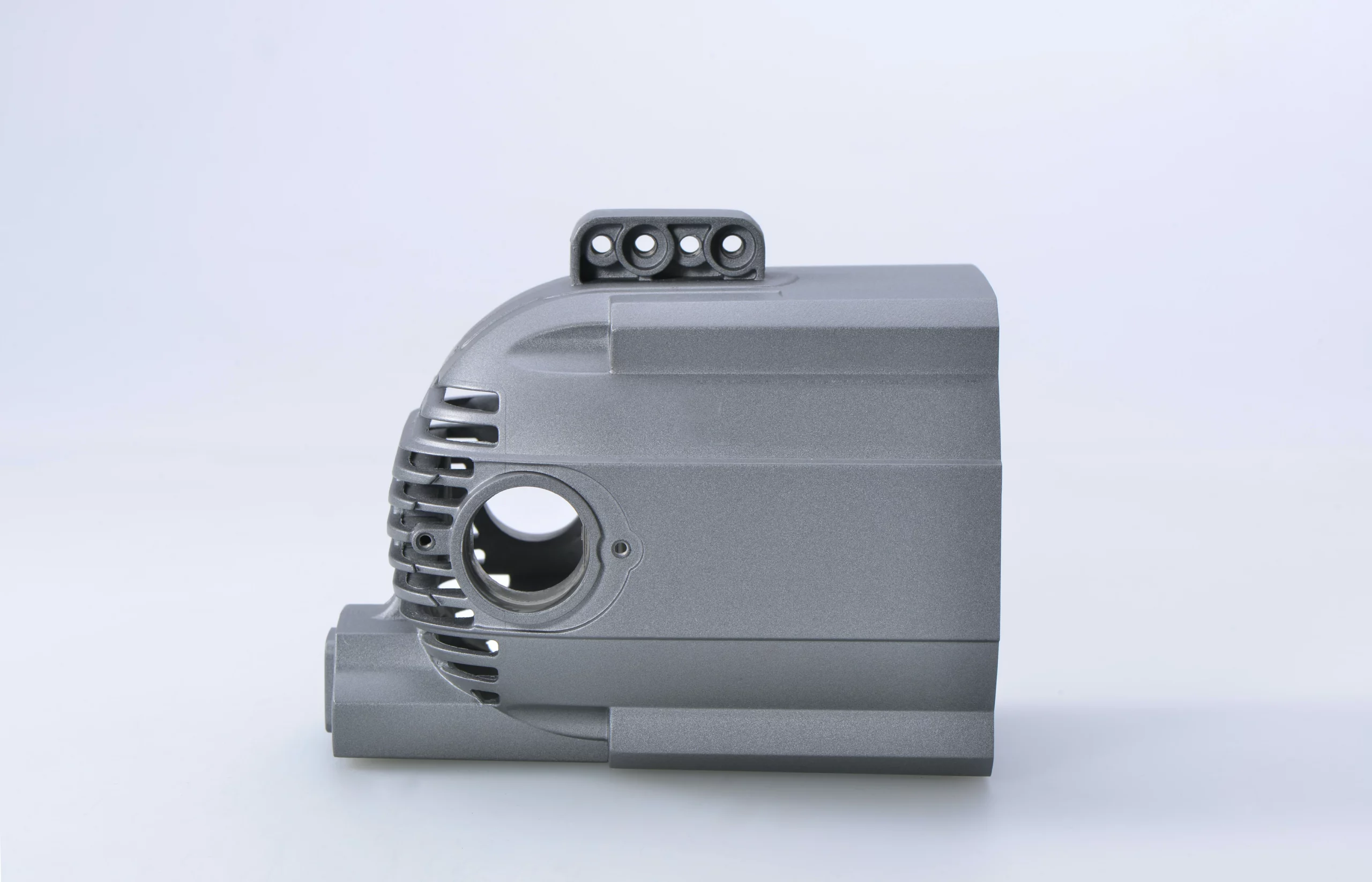

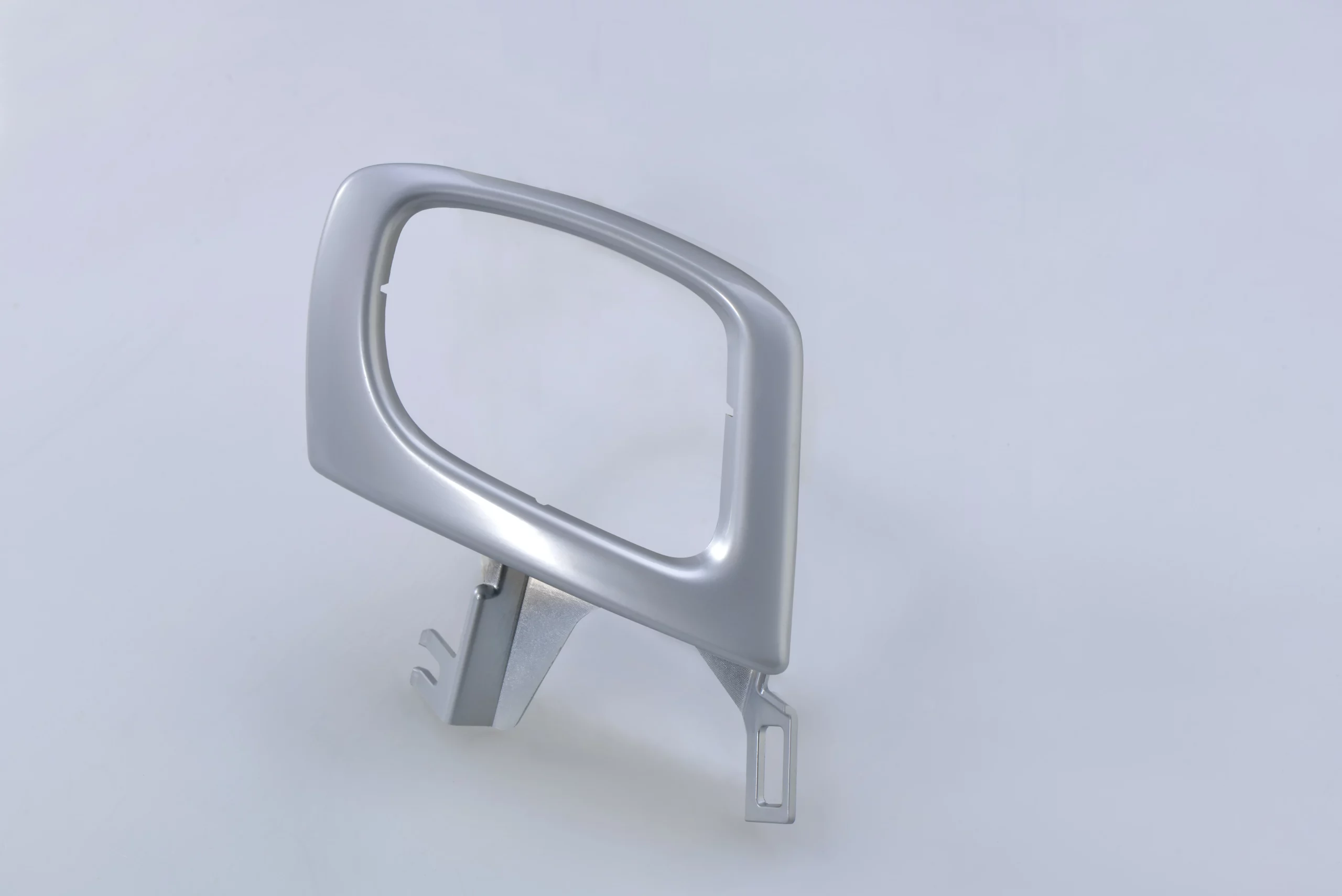

Gallery of Die Casting Parts

Overview: What is Die Casting?

Die casting is a metal manufacturing process, also known as pressure die casting or pressure casting.

For high-volume production of comparatively complex metal parts, die casting is the most suitable manufacturing process. During this process, high pressure is usually used to inject molten metal into the mold to ensure that the mold is filled and the desired shape of the part or product is obtained. Most metal parts involved in die casting technology.

Die casting technology is widely used in the automotive industry, aerospace, electronic equipment, household appliances, industrial machinery and other fields, producing various components and products.

About Die Casting FAQ

We offer a variety of surface treatment and coating options such as anodizing, electrophoretic coating and more to improve corrosion resistance, appearance and functionality.

We can handle die-casting parts of different sizes, but the specific minimum and maximum sizes depend on the material and design. Please contact [email protected] To obtain more detailed size limit information.

We offer flexible order quantities based on customer requirements, catering to both low volume and high volume production. Specific volumes depend on the project.

The steps involved in the die-casting process typically include:

1.Mold Preparation: The mold needs to be heated to a specific temperature and coated with a refractory coating or lubricant inside to ensure smooth metal injection and demolding.

2.Material Injection: Solid metal alloys are melted into a liquid state and then injected into the mold under the required pressure.

3.Cooling: After the metal is injected, sufficient time is allowed for it to cool and solidify, taking the shape specified by the mold.

4.Mold Opening: Once the metal has cooled, the mold is carefully opened, and the casted part is removed.

5.Trimming and Finishing: Finally, the casted part is trimmed, sharp edges are removed, and any excess material is cut away to achieve the desired shape and size of the final product.