CNC Milling Services

CNC milling services that support rapid prototyping design and production needs. Covering over 50 types of customized milling parts for high-quality metal and plastic materials.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Home » CNC Machining » CNC Milling

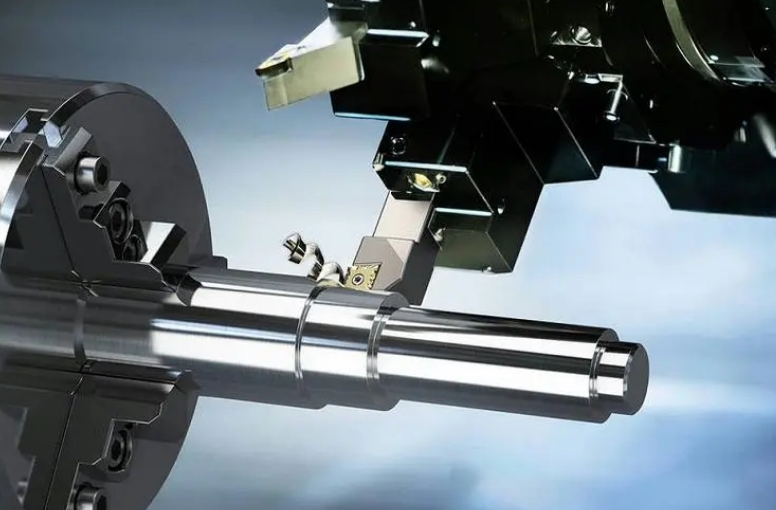

What is CNC Milling?

CNC milling is a method of using computer-controlled milling machines to cut metal or plastic. It includes 3-axis, 4-axis, and 5-axis milling. 3-axis milling moves the tool in three directions, with an additional rotation axis on the 4-axis and two rotation axes on the 5-axis, allowing the tool to cut workpieces more flexibly and handle more complex geometric shapes and surfaces.

Boyi 3-Axis, 4-Axis, 5-Axis CNC Milling Capabilities

Our CNC milling machines come in various types, from standard 3-axis to complex 5-axis projects. Our precision CNC milling technology customizes milling parts with excellent precision and craftsmanship.

|

|

Metric units

|

Imperial units

|

|

|---|---|---|---|

|

Maximum Part Size

|

4000 mm×1500 mm×600 mm

|

158 in.×590 in.×24 in.

|

|

|

Minimum Part Size

|

1 mm×1 mm

|

0.04 in.×0.04 in.

|

|

|

Linear Dimension

|

±0.025 mm

|

±0.001 in.

|

|

|

Shaft Diameters

|

±0.025 mm

|

±0.001 in.

|

|

|

Hole Diameters (Not Reamed)

|

±0.02 mm

|

±0.0008 in.

|

|

|

Tolerances

|

±0.01 mm

|

±0.0004 in.

|

|

Kindly ensure to explicitly denote the customized tolerance values on the engineering blueprints.

CNC Milling Materials

In addition to plastics and metals, CNC milling is also used to mill various allowable materials and other customized materials according to your requirements. Please contact [email protected] .

Metal

- Aluminium

- Brass

- Inconel

- Tool Steel

- Tool Steel

- Titanium

- Alloy Steel

- Stainless steel

- Copper

- Low Carbon Steel

Plastics

- Nylon

- ABS

- PMMA

- PET

- PEI

- PEEK

- PMMA (Acrylic)

- Polycarbonate

- Polyethylene

- POM

- Polypropylene

- HDPE

- PS

- PVC

- LDPE

- PPSU

- CPVC

- PSU

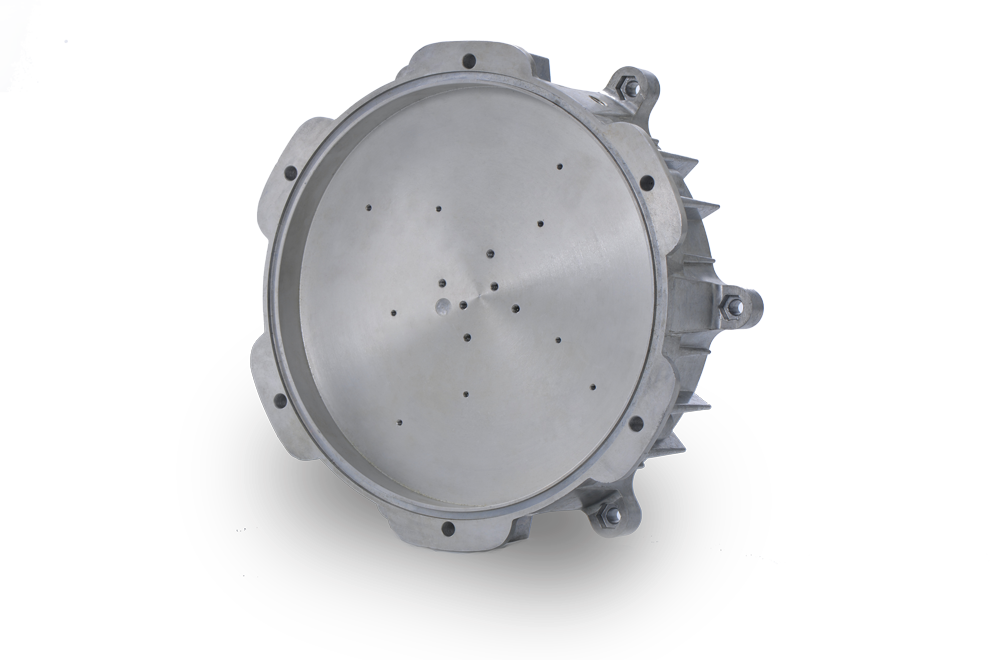

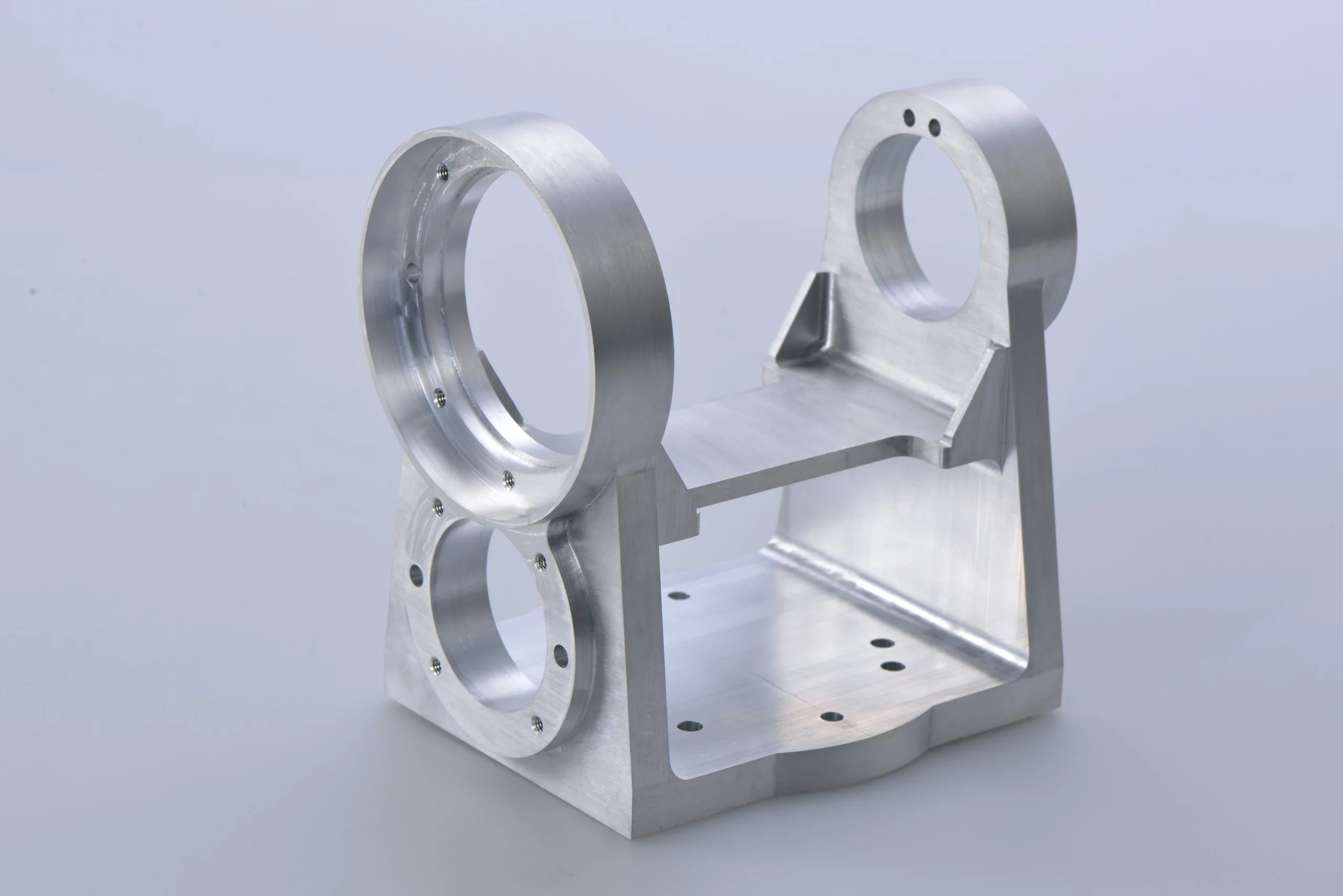

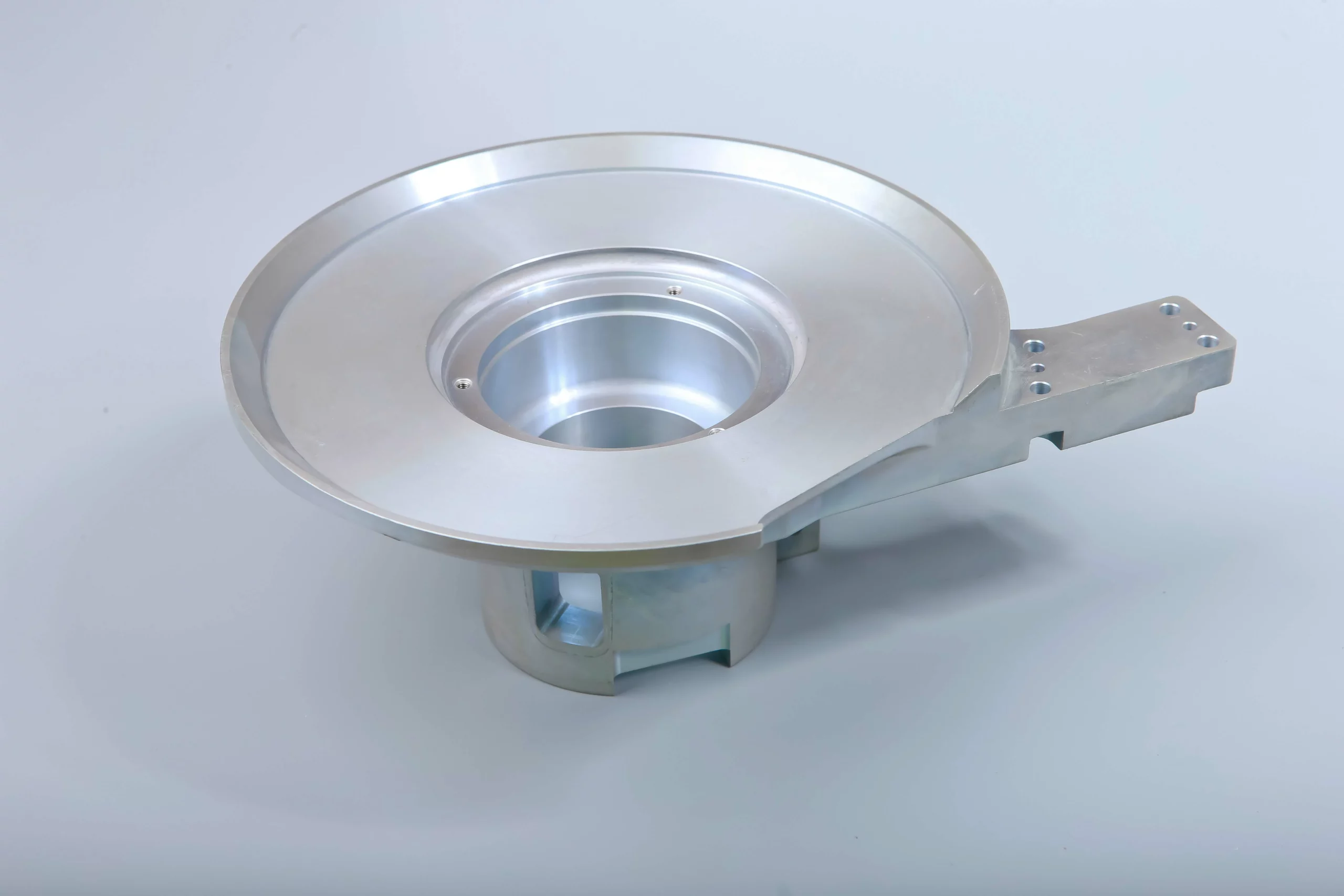

Gallery of Custom CNC Milling Parts

Following shows precision milling prototypes and parts from our esteemed customers.

About CNC Milling FAQs

Yes, we can provide sample or prototype production services according to your requirements. Whether you need low-volume manufacturing or a single sample, we can meet your needs.

The choice of axis depends on the complexity of your project. Typically, for simple flat and simple curved surfaces, 3-axis milling is sufficient. If more axis movements are required to handle complex geometries and surfaces, 4-axis or 5-axis milling would be more suitable.

By utilizing the latest CNC milling capabilities, Boyi can produce high-precision and fast milling parts within 48 hours. We strive to ensure high efficiency and timely delivery.

Offers high-precision tolerances, including sub +/- 0.01mm tolerances. We are the experts in making parts that are truly custom and ready to use.

CNC Milling Resources

Learn more about the working principle of CNC milling and how to design parts to fully utilize this machining process.