In the realm of machining and engineering. Two critical parameters that often come into play when discussing cutting tools, particularly in the context of threaded components, are the helix angle and lead angle. While they both pertain to the angular orientations of tool features, they serve distinct purposes and possess unique characteristics. Let’s delve into these differences to gain a clearer understanding.

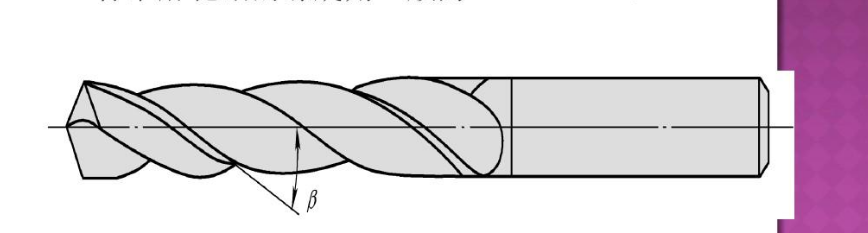

What is helix angle?

The helix angle is a fundamental property of helical tools, such as drills, end mills, and taps. It refers to the inclination angle of the helical line on a rotating object. In mechanical engineering, the helix angle is commonly used to describe the geometric characteristics of components such as helical gears, twist drills, and threads. The calculation of the helix angle is typically done by measuring the angle between the helical line and the axis. Its units are usually degrees (°) or radians (rad).

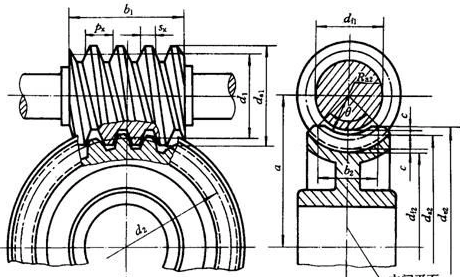

In practical applications, the size of the helix angle affects the performance and operational characteristics of rotating components. For example, in helical gears, the choice of helix angle influences transmission efficiency, noise levels, and load-bearing capacity. A larger helix angle typically implies larger tooth clearance and lower transmission efficiency, while a smaller helix angle generally has higher transmission efficiency and tighter meshing.

What is a lead angle?

The lead angle, also known as the pitch angle or thread angle, in contrast to the helix angle, the lead angle primarily pertains to the geometry of threaded components, such as screws, bolts, and taps. It represents the angle between the helix of the threads and a line parallel to the axis of the threaded feature.

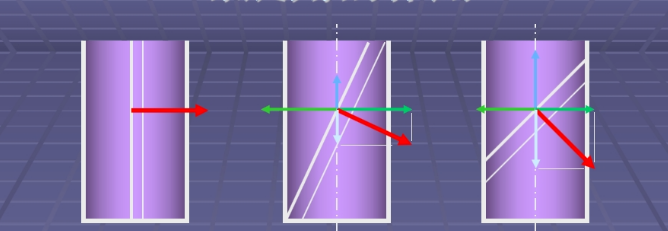

In machining, the lead angle is commonly used to describe the motion trajectory of the tool during thread cutting or helical machining. The size of the lead angle depends on the feed rate and rotational speed of the tool, as well as the geometric shape of the workpiece.

The lead angle is calculated by the ratio between the feed rate and the rotational speed of the tool. It is typically expressed in degrees (°) or radians (rad).

What’s the difference between a helix angle and lead angle?

Helix angle and lead angle play important roles in thread design and mechanical calculations, with main differences reflected in their definitions, functions, and measurement methods.

1.Definitions:

- Helix angle: The helix angle refers to the angle between the tangent at any point on a cylindrical or conical helical curve and the axis of the helix at that point. For example, worm gears. In a worm gear, the helix moves forward along the axis, forming the helical shape of the gear. The helix angle determines the slope and meshing characteristics of the worm gear.

- Lead angle: Also known as the thread lead angle, it is the angle between the tangent to the helix on the median cylinder or median cone and the plane perpendicular to the axis of the thread. This angle determines the shape and dimensions of the thread and is a key parameter in thread design.

2.Functions:

- Helix angle: The helix angle primarily affects the self-locking performance of the thread. A larger helix angle means a greater degree of inclination, making the thread more prone to self-locking, i.e., less likely to loosen spontaneously in the absence of external forces. Additionally, the helix angle affects the direction of rotation of the thread, whether it is clockwise or counterclockwise.

- Lead angle: The lead angle is mainly used to determine the mating properties and engagement length of the thread. By adjusting the lead angle, the engagement length and tightness of the thread can be controlled. Moreover, the lead angle also affects the transmission performance of the thread, such as in worm gear transmissions, where the lead angle of the worm determines the efficiency and stability of the transmission.

3.Measurement methods:

- The helix angle is typically measured using specialized tools such as helix angle measurement instruments. During measurement, the probe of the measuring instrument is placed on the tangent of the thread, and the helix angle is obtained from the reading of the instrument.

- The measurement and calculation of the lead angle can be achieved using the formula “Tangent of alpha = Lead / (Median Diameter × 3.14)”. Here, the lead refers to the axial distance between adjacent teeth on the same helix at points corresponding to the median diameter, and the median diameter is a specific diameter on the thread axis.

Table 1: A simple table to summarize their differences:

| Feature | Lead Angle | Helix Angle |

|---|---|---|

| Definition | The angle formed by the helix of the thread with the axis of the screw. | The angle formed by the tangent of the helix at any point and a plane perpendicular to the axis of the screw. |

| Symbol | θ (theta) | β (beta) |

| Measurement | Measured in degrees or radians. | Measured in degrees or radians. |

| Purpose | Determines the axial movement of the nut per revolution of the screw. | Indicates the efficiency of the screw in transmitting power and the self-locking ability. |

| Influence | Affects the linear movement of the nut along the screw. | Affects the torque required to drive the screw and the axial force exerted by the screw. |

| Design Consideration | Important in screw and nut design to ensure proper linear motion. | Important in screw design for efficiency and self-locking properties. |

| Calculation | Lead angle = tan<sup>-1</sup>(Lead / (2π * Diameter)) | Helix angle = tan<sup>-1</sup>(Lead / Pitch) |

| Example | A lead angle of 5 degrees means the nut advances 5 mm along the screw axis with each revolution. | A helix angle of 30 degrees means the screw makes one complete turn every 30 degrees of axial distance. |

The advantages and disadvantages of lead angle and helix angle in mechanical design

In mechanical design, the use of lead angle and helix angle each has its own advantages and disadvantages, as follows:

Advantages of lead angle:

- Improved transmission efficiency: A larger lead angle can increase the linear velocity of the screw, enabling larger linear displacement at the same rotational speed, thus enhancing transmission efficiency.

- Increased speed: In applications requiring rapid movement, choosing a larger lead angle can achieve faster movement speeds, improving operational efficiency.

- Reduction in screw length: By increasing the lead angle, larger displacements can be achieved at the same pitch, thereby reducing the length of the screw and saving space.

Disadvantages of lead angle:

- Increased sliding friction: Larger lead angles can increase the friction between the screw and nut, potentially leading to decreased transmission efficiency and increased wear.

- Decreased load capacity: An increase in lead angle may reduce the effective cross-sectional area of the screw, thus decreasing its load capacity and stiffness.For example, the common thread forms in automotive fasteners, such as bolts, nuts, and screws, need to consider the lead angle in their design to meet specific engineering requirements.

- Poor stability: Larger lead angles may make it easier for the screw to experience vibration and instability during motion, affecting system stability and precision.

Advantages of helix angle:

- Enhanced strength and stiffness: A larger helix angle can increase the inclination of the screw’s helical thread, helping to improve the screw’s strength and stiffness.

- Reduced sliding friction: Appropriate helix angles can decrease the friction between the screw and nut, enhancing transmission efficiency and performance stability.

- Lower vibration and noise: Suitable helix angles can reduce vibration and noise during screw motion, improving system stability and comfort.

Disadvantages of helix angle:

- Increased manufacturing cost: Larger helix angles may require higher precision machining and manufacturing processes, leading to increased manufacturing costs and complexity.

- Increased frictional losses: Excessive helix angles may increase the friction between the screw and nut, resulting in energy losses and exacerbated wear.

- Increased space occupation: Larger helix angles may cause an increase in the screw’s lengthwise dimension, occupying more installation space.

Designers need to balance the advantages and disadvantages of lead angle and helix angle based on specific application requirements and design considerations to select the most appropriate parameters for achieving the optimal design outcome.

Put your parts into production today

How to choose the helix angle and lead angle the thread design process?

In the process of designing threads, selecting the helix angle or pitch angle involves considering multiple factors, including usage scenarios, functional requirements, machining, and assembly conditions. Here are some guiding principles and recommendations:

Consider usage scenarios and functional requirements:

- If the thread needs to have strong self-locking ability, such as in applications subject to vibration or impact loads, a larger helix angle can be chosen. A larger helix angle increases the thread’s self-locking ability, preventing loosening.

- If the thread needs to transmit large torque or withstand significant axial loads, a smaller helix angle can be selected. A smaller helix angle enhances the thread’s load-bearing capacity and stability.

Consider machining and assembly conditions:

- Consider the difficulty of thread machining. A larger helix angle may make thread machining difficult, especially when using traditional cutting tools. Therefore, when selecting the helix angle, evaluate the machining equipment and process capabilities.

- Consider friction during assembly. A smaller helix angle may increase friction during assembly, making it challenging. Therefore, in situations where threads need frequent assembly or disassembly, a larger helix angle can be chosen to reduce friction.

Refer to standards and specifications:

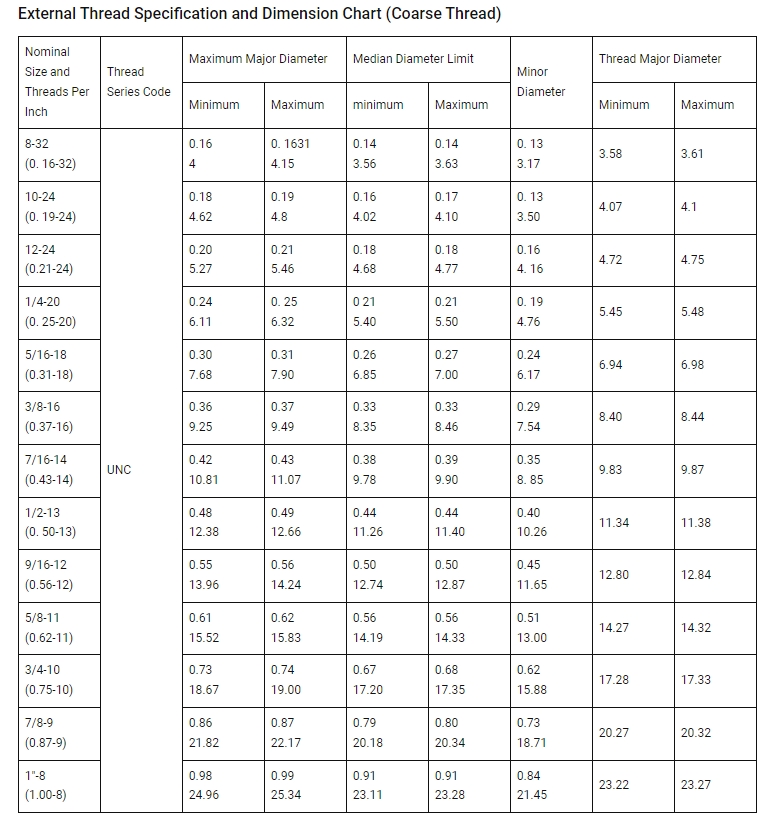

- When designing threads, it is recommended to refer to relevant standards and specifications, such as ISO, DIN, ANSI, etc. These standards and specifications provide recommended values for thread dimensions, helix angles, and pitch angles, serving as design references.

Below are some common ANSI thread standard thread size range recommendations:

Unified Coarse Thread (UNC):

Minimum thread diameter (inches): #0 (0.060 inches) to 4 (0.437 inches)

Maximum thread diameter (inches): #0 (0.094 inches) to 4 (0.484 inches)

Pitch (threads per inch): Varies from coarse to fine depending on specific sizes.Unified Fine Thread (UNF):

Minimum thread diameter (inches): #00 (0.036 inches) to 12 (0.750 inches)

Maximum thread diameter (inches): #00 (0.086 inches) to 12 (0.794 inches)

Pitch (threads per inch): Finer than the corresponding UNC threads, typically used for applications requiring higher precision and tighter fits.Unified Extra Fine Thread (UNEF):

Minimum thread diameter (inches): #000 (0.019685 inches) to 4 (0.250 inches)

Maximum thread diameter (inches): #000 (0.029528 inches) to 4 (0.29528 inches)

Pitch (threads per inch): Extremely fine, typically used for applications requiring higher precision and smaller clearances.

Thread Size Chart (inch/mm)

Screw Tap Drill Size Chart (Metric/Inch/US)

Conduct experimentation and validation:

- After determining the helix angle or pitch angle, it is advisable to conduct experiments and validation. Through practical usage testing, the thread’s performance and reliability can be assessed, and adjustments and optimizations can be made as needed.

The specific applications of helix angle and lead angle in thread design?

Application of helix angle and lead angle in thread design:

Helix angle application:

- Direction determination: The helix angle determines the rotation direction of the thread, whether it is clockwise or counterclockwise. This is important for guiding the assembly and use direction of the thread.

- Self-locking performance: The size of the helix angle directly affects the self-locking performance of the thread. A larger helix angle can enhance the self-locking of the thread, making it less prone to loosen or slip when subjected to external forces. This is particularly important in applications requiring high fastening and sealing performance.

- Stress analysis: The helix angle is an important parameter in thread stress analysis. By considering the helix angle, the stress distribution and deformation of the thread under load can be analyzed, guiding the optimization of thread design.

Application of lead angle:

- Fit properties: The size of the lead angle determines the fit properties of the thread. An appropriate lead angle ensures tight fit between threads, improving the joint strength and sealing of the thread.

- Engagement length: The lead angle also affects the engagement length of the thread. By adjusting the lead angle, the depth and length of thread engagement can be controlled to meet different design requirements.

- Error compensation: In some cases, the lead angle can also be used for error compensation. For example, in situations where there is significant gear error in machine tool gear exchange, adjusting the lead angle can effectively reduce the helix angle error when hobbing gears.

By carefully selecting and adjusting these two parameters, the performance and reliability of the thread can be optimized to meet different design requirements and usage scenarios.

Conclusion

While helix angle and lead angle share similarities in their association with helical structures, they serve distinct functions in machining operations. Understanding the disparities between these angles is essential for optimizing machining processes, ensuring precision, and achieving desired performance outcomes in manufacturing applications.Or learn more about CNC machining information

BOYI possesses advanced machining equipment and an experienced technical team capable of meeting various complex machining needs. Through BOYI’s CNC machining services, you can experience the precision, quality, and efficiency of all machining projects.

Put your parts into production today

FAQ

The advantage of a helix angle lies in its ability to facilitate efficient chip evacuation, reduce cutting forces, improve surface finish, and enhance tool stability during machining operations.

The main difference between thread angle and helix angle is their focus: thread angle pertains to the angle formed by the flanks of the threads on a threaded component, while helix angle refers to the angle formed between the helical path of a cutting tool or structure and its axis of rotation during machining operations.

The lead angle of a helical gear is the angle formed between the tangent to the helix and the gear’s axis. It determines the axial movement of the teeth during one complete revolution of the gear. In contrast, the helix angle of a helical gear is the angle between the helix’s tangent and the gear’s axis, defining the helical shape of the gear teeth. Both lead angle and helix angle play crucial roles in the operation and performance of helical gears, influencing factors such as load distribution, smoothness of operation, and noise levels.