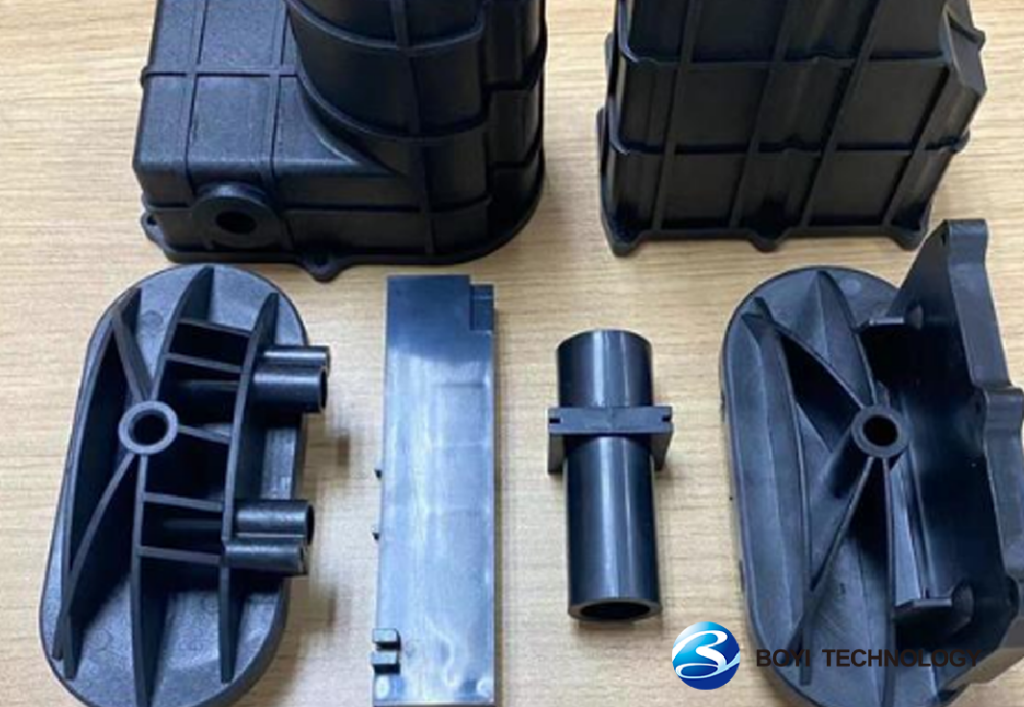

Rubber molding can be used to manufacture various rubber products with different properties and uses. From complex automotive components to elastic seals and durable consumer goods, rubber molding technology provides unparalleled versatility and precision in shaping rubber raw materials into functional forms.

In this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their applications, advantages, and pivotal role in shaping the landscape of modern manufacturing.

What is rubber molding called?

Rubber molding refers to the process of shaping raw rubber material into various forms and products using molds and specific manufacturing techniques. This process is also known simply as molding or rubber molding. Depending on the specific method used, such as injection molding, compression molding, or transfer molding, the process may be referred to by the specific technique employed, but “rubber molding” is the overarching term that encompasses these methods.

3 types of rubber molding processes

Rubber molding processes are used to create various rubber products with different properties and applications. Here are three common types of rubber molding processes:

What is rubber injection molding?

Rubber injection molding is a specialized manufacturing process used to produce rubber parts and components by injecting molten rubber material into a mold cavity under high pressure. This process is particularly suited for creating complex shapes, precise dimensions, and intricate details in rubber products.

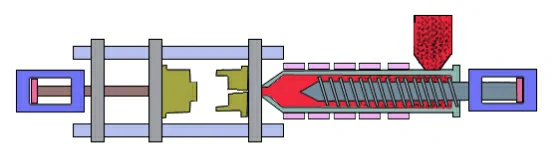

Rubber injection molding process

The following are the process steps for rubber injection molding:

- Material Preparation: Rubber material is typically prepared in the form of pellets, strips, or preforms. The raw rubber material is then fed into a hopper and heated until it reaches a molten state.

- Injection: The heated rubber material is injected into a closed mold cavity through a nozzle or sprue under high pressure. The mold is usually made of two halves, which are clamped together during the injection process. The injection pressure ensures that the molten rubber fills the entire cavity and takes the shape of the mold.

- Cooling: Once the mold cavity is filled, the injected rubber material begins to cool and solidify, conforming to the shape of the mold. Cooling may be accelerated by circulating coolant through the mold or using other cooling methods.

- Curing: After the part has cooled sufficiently, it undergoes a curing process to further cross-link the rubber molecules and improve its mechanical properties. Curing may involve heat, pressure, or chemical additives, depending on the specific requirements of the rubber material used.

- Ejection: Once the part has been cured and reached its final form, the mold opens, and the finished part is ejected from the mold cavity using ejector pins or other mechanisms.

Rubber injection molding advantages

Rubber injection molding offers several advantages over other rubber molding processes, including:

- Precision and Complexity: Injection molding allows for the production of highly precise and complex rubber parts with intricate geometries and tight tolerances. This is achieved through the use of precision molds and controlled injection parameters.

- Efficiency: Injection molding is a high-speed process, capable of producing large quantities of rubber parts in a relatively short amount of time. This leads to increased productivity and lower production costs per part.

- Material Utilization: Injection molding minimizes material waste by precisely controlling the amount of rubber injected into the mold cavity. This results in higher material utilization rates compared to other molding processes, reducing material costs and environmental impact.

- Consistency and Quality: Injection molding provides excellent repeatability and consistency in part dimensions and properties. This ensures uniformity in product quality, reducing variability and the likelihood of defects.

- Versatility: Injection molding can be used to manufacture a wide range of rubber parts, from small components to large, complex assemblies. It is suitable for various elastomers, including natural rubber, silicone, EPDM, and fluoroelastomers, making it a versatile manufacturing solution.

- Design Flexibility: Injection molding allows for the integration of multiple features and functionalities into a single part, such as undercuts, inserts, and overmolding. This design flexibility enables the creation of innovative and multifunctional rubber products to meet diverse application requirements.

Rubber injection molding disadvantages

Although rubber injection molding has many advantages, it also has some disadvantages and limitations:

- Longer Setup Time: Compared to other rubber molding processes like compression molding, injection molding typically involves longer setup times due to the preparation of molds, calibration of injection parameters, and testing of process conditions. This can lead to higher initial production lead times and slower turnaround for new part introductions.

- Longer Setup Time: Compared to compression molding technology, injection molding typically requires longer setup time due to mold preparation, calibration of injection parameters, and testing of process conditions. This may lead to higher injection molding costs, as well as slower initial production lead times and the introduction of new parts turnover time.

- Part Size Constraints: Rubber injection molding is best suited for producing small to medium-sized parts due to equipment limitations and cycle time considerations. Producing very large or thick-walled parts may require specialized machinery or multiple injection cycles, leading to increased production costs and complexity.

Rubber injection molding applications

Despite these drawbacks, rubber injection molding still has a wide range of applications:

- Automotive Industry: Rubber injection molding is used to manufacture automotive seals, windshield seals, suspension parts, etc. These parts require high precision and high-performance rubber materials, and are often produced on a large scale to meet the needs of automotive manufacturers.

- Medical Devices: The medical industry requires many rubber seals, fittings, and hoses to ensure the sealing performance and safety of equipment. Rubber injection molding provides a reliable method for producing these components while ensuring compliance with the stringent standards and regulations of the medical industry.

- Electronics: Many electronic products require rubber seals and dust covers to prevent dust, moisture, and other impurities from entering the equipment. Rubber injection molding can produce parts with precise dimensions and complex geometries to meet the requirements of electronic product manufacturers.

- Consumer Goods: Rubber injection molding is used to produce various consumer goods such as shoes, gloves, toys, etc. These products often require soft, durable, and specific-shaped rubber materials, which injection molding can meet while achieving large-scale production.

What is rubber compression molding?

Rubber compression molding is a manufacturing process used to produce various rubber products, such as seals, gaskets, O-rings, and automotive parts.It involves the use of a mold cavity that is typically made of metal, into which raw rubber material is placed. The mold is then closed, and heat and pressure are applied to the material, causing it to conform to the shape of the mold cavity,is particularly suitable for producing large or intricate parts.

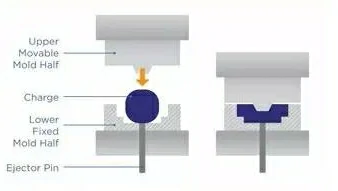

Rubber compression molding process

Here’s a basic overview of the rubber compression molding process:

- Preparation of Raw Material: The process begins with raw rubber material, typically in the form of pellets, sheets, or preforms. These materials are selected based on the desired properties of the final product.

- Mold Design and Preparation: A mold, usually made of metal, is designed to the specifications of the desired part. The mold is typically split into two halves, with a cavity inside that corresponds to the shape of the final product. The mold may also include additional features such as vents and gates to facilitate the flow of rubber material.

- Loading the Mold: The rubber material is placed into the mold cavity manually or using automated equipment. Excess material is often added to ensure that the mold is completely filled during the compression process.

- Compression and Heating: The mold halves are closed and clamped together, and then subjected to high pressure to compress the rubber material. Additionally, heat is applied to soften the rubber and aid in the flow into the mold cavity. The combination of pressure and heat helps the rubber material conform to the shape of the mold.

- Curing: Once the rubber material has filled the mold cavity, it is kept under pressure and heat for a specific period, allowing the material to cure and solidify into the desired shape. The curing process may involve vulcanization, where chemical additives or sulfur are used to cross-link the rubber molecules, imparting strength and durability to the final product.

- Cooling and Demolding: After curing, the mold is cooled to allow the rubber to set completely. The mold is then opened, and the finished rubber part is removed. Any excess material (flash) is trimmed off, and the part may undergo additional finishing processes such as inspection, surface finishing, or quality control checks.

Rubber compression molding advantages

Rubber compression molding offers several advantages, including:

- Suitability for Large Parts: Compression molding is well-suited for producing large parts or parts with thick cross-sections.

- Lower Tooling Costs: Compared to processes like injection molding, compression molding typically involves lower tooling costs, making it more cost-effective for smaller production runs.

- Ability to Mold Reinforcements: Reinforcing materials such as fabric or metal inserts can be placed in the mold cavity before compression, allowing for the production of reinforced rubber parts.

Rubber compression molding disadvantages

Although rubber compression molding has many advantages, it also has some disadvantages and limitations:

- Longer Cycle Times: Compared to other rubber molding processes like injection molding, compression molding typically requires longer cycle times. Due to the heating and cooling processes involved in compression molding, production cycles are longer, affecting production efficiency.

- Limitations in Shapes and Sizes: Since rubber can only flow along the axis of the mold during compression molding, the parts produced are often limited to simple shapes and larger sizes. This makes it challenging to produce complex shapes or small parts.

- Material Waste: Cutting and trimming of rubber material in the mold may result in significant waste and scrap. This increases costs and has negative environmental impacts.

Rubber compression molding applications

Some common applications include:

- Seals and Gaskets: Rubber compression molding is extensively used in the production of seals and gaskets for various applications, including automotive engines, industrial machinery, plumbing systems, and hydraulic equipment.

- Automotive Components: Compression-molded rubber parts are found in numerous automotive components, such as engine mounts, suspension bushings, grommets, weatherstrips, and vibration dampers. These components contribute to vehicle performance, comfort, and safety by providing cushioning, noise reduction, and isolation from vibrations.

- Electrical Insulation: Rubber compression molding is used to manufacture electrical insulation components such as cable glands, wire grommets, insulating boots, and electrical connectors. These components protect electrical connections from environmental factors, provide strain relief, and ensure safety in electrical systems.

- Consumer Products: Compression-molded rubber is employed in various consumer products, including sporting goods, kitchen appliances, household tools, and toys. Examples include rubber grips for hand tools, rubberized handles for cookware, protective bumpers for electronics, and rubber components for sporting equipment.

- Medical Devices: Rubber compression molding is utilized in the production of medical devices and equipment, such as seals, gaskets, diaphragms, and syringe components. These medical-grade rubber parts meet stringent quality standards, ensure biocompatibility, and provide sealing and cushioning properties in medical applications.

- Marine and Offshore: Rubber compression molding is employed in marine and offshore applications for seals, gaskets, bushings, and vibration mounts. These components resist corrosion, withstand exposure to saltwater, and provide reliable sealing and cushioning in marine environments.

What is rubber transfer molding?

Rubber transfer molding is a manufacturing process used to produce rubber parts or components with complex shapes, tight tolerances, and consistent quality. It is a variation of compression molding and injection molding processes.

In rubber transfer molding, raw rubber material is placed into a heated cavity (mold) through a system of sprues and runners. The mold is typically made of metal and contains a cavity in the shape of the desired final product. The rubber material can be in the form of preforms, pellets, or sheets depending on the specific requirements of the part.

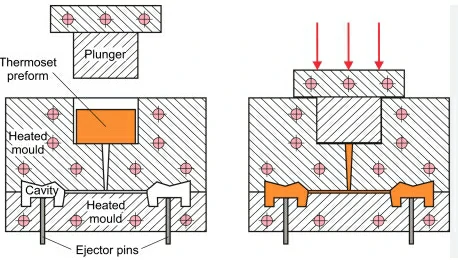

Rubber transfer molding process

The process involves several steps:

- Preparation of Mold: The process begins with the preparation of a mold, which is typically made of metal (such as aluminum or steel). The mold is designed to the exact specifications of the desired rubber product.

- Preparation of Rubber: The rubber material, usually in the form of pellets or preforms, is prepared. It can be natural rubber or synthetic rubber compounds, depending on the application and required properties of the final product.

- Loading the Mold: The mold is opened, and a precise amount of rubber material is placed into a chamber or pot located above the mold cavity.

- Heating: The mold is closed, and heat and pressure are applied. The rubber material in the chamber is heated until it reaches a softened or molten state.

- Transfer: Once the rubber reaches the desired consistency, a plunger or piston forces the material into the mold cavity through a sprue or runner system. This transfer of the rubber from the chamber to the mold cavity gives the process its name.

- Curing: After the mold cavity is filled, the entire mold assembly is transferred to a curing press or oven. Heat and pressure are applied to cure the rubber, cross-linking the polymer chains and giving the product its final shape and properties.

- Cooling and Demolding: After curing is complete, the mold is cooled, and the pressure is released. The cured rubber part is then removed from the mold cavity, either manually or using automated demolding equipment.

Rubber transfer molding advantages

Rubber transfer molding offers several advantages compared to other rubber molding processes, such as compression molding and injection molding. Some of the key advantages include:

- Precision and Complexity: Transfer molding allows for the production of rubber parts with intricate details and complex geometries. This makes it suitable for manufacturing parts with tight tolerances and intricate designs, which may not be achievable with other molding processes.

- Material Control: Transfer molding provides better control over material placement compared to compression molding. This results in more uniform part properties, reduced material waste, and improved consistency in part dimensions.

- Faster Cycle Times: Transfer molding typically offers faster cycle times compared to compression molding. This makes it more suitable for high-volume production runs, leading to increased productivity and efficiency.

- Flexibility in Material Selection: Transfer molding can accommodate a wide range of rubber materials, including various elastomers and compounds with different properties. This flexibility allows manufacturers to select the most suitable material for their specific application requirements.

- Lower Tooling Costs: While the initial tooling costs for transfer molding may be higher than compression molding, they are typically lower than those for injection molding. This makes transfer molding a cost-effective option for producing medium to high volumes of rubber parts.

Rubber transfer molding disadvantages

Some of the key disadvantages include:

- Higher Initial Tooling Costs: Transfer molding often involves higher initial tooling costs compared to compression molding. The molds used in transfer molding are typically more complex and expensive to design and manufacture, especially for parts with intricate geometries or tight tolerances.

- Longer Cycle Times: Transfer molding generally has longer cycle times compared to injection molding. The process involves additional steps such as preheating the material in the pot, transferring it to the mold cavity, and curing the part. These additional steps contribute to longer overall cycle times, reducing production efficiency.

- Material Waste: Transfer molding can generate more material waste compared to injection molding, particularly due to the need for sprues and runners to deliver the material to the mold cavity. This can result in higher material costs and increased environmental impact.

- Complex Process Control: Transfer molding requires precise control of various parameters such as temperature, pressure, and material flow to ensure consistent part quality. Achieving and maintaining optimal process conditions can be challenging and may require skilled operators and sophisticated equipment.

- Limited Part Size: Transfer molding may be less suitable for producing very large or very small parts compared to other molding processes. Mold design and material flow considerations can limit the size and complexity of parts that can be effectively produced using transfer molding.

Rubber transfer molding applications

Rubber transfer molding finds diverse applications across various industries due to its ability to produce complex rubber parts with precision and efficiency. Some of the common applications of rubber transfer molding include:

- Automotive Components: Rubber transfer molding is extensively used in the automotive industry for manufacturing a wide range of rubber components such as seals, gaskets, O-rings, bushings, and vibration dampers.

- Electrical and Electronic Devices: Rubber transfer molding is employed in the production of rubber seals, grommets, insulators, and connectors for electrical and electronic devices. These components provide protection against moisture, dust, and electrical interference, enhancing the reliability and longevity of electronic equipment.

- Consumer Goods: Rubber transfer molding is utilized in the production of consumer goods such as footwear, sporting goods, toys, and household appliances. It enables the fabrication of rubber components with intricate designs, customized shapes, and enhanced durability to meet consumer demands.

- Industrial Equipment: Rubber transfer molding is employed in industrial applications to produce seals, gaskets, hoses, and other rubber components for machinery, pumps, valves, and hydraulic systems.

- Aerospace and Defense: Rubber transfer molding is utilized in the aerospace and defense sectors for manufacturing rubber seals, gaskets, O-rings, and vibration isolators used in aircraft, spacecraft, missiles, and military vehicles.

- Fluid Handling Systems: Rubber transfer molding is used in the production of rubber components for fluid handling systems, including seals, diaphragms, valves, and connectors used in pumps, pipelines, and fluid control devices.

Rubber molding – Rubber product type

There are several types of rubber parts used in rubber molding, each serving different purposes and applications. Here are some common types:

Certainly, let’s delve even deeper into each type of rubber part used in rubber molding, exploring their characteristics, applications, and manufacturing processes:

1.O-rings

- Characteristics: O-rings are typically made from elastomeric materials like nitrile rubber (NBR), silicone, EPDM, fluorocarbon (Viton), or neoprene. They feature a round cross-section, which allows them to fit snugly into grooves or cavities.

- Applications: O-rings are widely used in hydraulic systems, pneumatic systems, automotive engines, pumps, and plumbing fixtures. They provide a reliable seal against fluids or gases, preventing leaks even under high pressures or varying temperatures.

- Manufacturing Process: O-rings are typically produced through compression molding or injection molding processes. Compression molding involves placing a preformed rubber compound into a mold cavity and subjecting it to heat and pressure until it takes the desired shape. Injection molding involves injecting molten rubber material into a mold cavity under high pressure.

2.Gaskets

- Characteristics: Gaskets can be made from various rubber materials, including silicone, EPDM, neoprene, nitrile rubber, and natural rubber. They come in different shapes and sizes, including ring gaskets, sheet gaskets, and custom-molded gaskets.

- Applications: Gaskets are used in a wide range of industries, including automotive, aerospace, plumbing, and manufacturing. They provide a tight seal between two mating surfaces, preventing fluid or gas leakage in engines, pipelines, valves, and machinery.

- Manufacturing Process: Gaskets are typically manufactured through compression molding or die-cutting processes. Compression molding involves compressing a rubber sheet or compound between heated mold plates to form the desired shape. Die-cutting involves cutting gasket shapes from rubber sheets using specialized dies.

3.Seals

- Characteristics: Seals are designed to prevent leakage between moving parts or components. They come in various configurations, including piston seals, rod seals, wiper seals, and rotary seals.

- Applications: Seals are used in hydraulic cylinders, pneumatic systems, pumps, valves, and rotating shafts. They provide a dynamic sealing solution, accommodating movement while maintaining a tight seal against fluids or gases.

- Manufacturing Process: Seals are typically manufactured through compression molding, injection molding, or machining processes. Compression molding and injection molding are suitable for producing seals with complex geometries, while machining is used for precision sealing surfaces.

4.Grommets

- Characteristics: Grommets are typically made from flexible rubber materials like EPDM, silicone, or neoprene. They feature a hollow center and flanged edges, allowing them to be inserted into holes or openings in surfaces.

- Applications: Grommets are used to protect and insulate cables, wires, or hoses passing through panels or enclosures. They provide a cushioned and sealed passage, preventing chafing, abrasion, or damage to the wires or cables.

- Manufacturing Process: Grommets are commonly manufactured through compression molding or injection molding processes. Compression molding involves forming the grommet shape in a heated mold cavity, while injection molding involves injecting molten rubber material into a mold cavity under pressure.

5.Bushings

- Characteristics: Bushings are cylindrical rubber components with a central void or hole. They are typically made from elastomeric materials like natural rubber, neoprene, or polyurethane.

- Applications: Bushings are used as cushions or insulators to reduce vibration, noise, or friction between two moving parts. They are commonly found in suspension systems, automotive engines, and industrial machinery.

- Manufacturing Process: Bushings can be manufactured through compression molding, injection molding, or machining processes. Compression molding and injection molding are suitable for producing bushings with complex shapes and intricate details, while machining is used for precise tolerances and finishes.

6.Bellows

- Characteristics: Bellows are accordion-like rubber parts with pleated or folded walls. They are typically made from flexible rubber materials like EPDM, neoprene, or silicone.

- Applications: Bellows are used to protect moving components from dust, dirt, moisture, or contaminants while allowing for expansion and contraction. They are commonly found in steering systems, CV joints, and industrial machinery.

- Manufacturing Process: Bellows can be manufactured through compression molding, injection molding, or extrusion processes. Compression molding and injection molding are suitable for producing bellows with complex shapes and folds, while extrusion is used for continuous production of bellows with uniform cross-sections.

7.Boots

- Characteristics: Boots are protective rubber covers designed to shield moving parts like joints or shafts from environmental elements. They are typically made from durable rubber materials like EPDM, neoprene, or silicone.

- Applications: Boots are commonly used in automotive steering systems, drive shafts, CV joints, and hydraulic cylinders. They protect critical components from contamination, moisture ingress, and premature wear, extending their lifespan and reliability.

- Manufacturing Process: Boots can be manufactured through compression molding, injection molding, or extrusion processes. Compression molding and injection molding are suitable for producing boots with complex shapes and details, while extrusion is used for continuous production of boots with uniform cross-sections.

8.Mounts

- Characteristics: Mounts are rubber components designed to isolate vibration or dampen shock between two components. They are typically made from elastomeric materials like natural rubber, neoprene, or polyurethane.

- Applications: Mounts are used in automotive engines, HVAC systems, machinery, and equipment to reduce noise, vibration, and harshness (NVH). They provide a cushioned interface between components, improving comfort, stability, and longevity.

- Manufacturing Process: Mounts can be manufactured through compression molding, injection molding, or casting processes. Compression molding and injection molding are suitable for producing mounts with complex shapes and configurations, while casting is used for large-scale production of mounts with specific performance characteristics.

What material is used for rubber molding?

Rubber molding materials come in various formulations, each tailored to specific applications based on factors like flexibility, durability, chemical resistance, and temperature stability. Here are some common rubber molding materials:

1.Natural rubber (NR)

- Natural rubber is derived from the latex sap of rubber trees and is known for its high elasticity and resilience.

- It offers excellent tear strength, abrasion resistance, and flexibility, making it suitable for applications requiring dynamic movement and high elasticity.

- Natural rubber is commonly used in products such as tires, conveyor belts, seals, gaskets, and shock absorbers.

2.Styrene butadiene rubber (SBR)

- SBR is a synthetic rubber that combines the properties of styrene and butadiene.

- It offers good abrasion resistance, resilience, and low-temperature flexibility.

- SBR is commonly used in tire manufacturing, conveyor belts, and footwear due to its affordability and versatility.

3.Nitrile rubber (NBR)

- NBR is a synthetic rubber known for its excellent oil and fuel resistance.

- It offers good mechanical properties, including high tensile strength, abrasion resistance, and flexibility over a wide temperature range.

- NBR is widely used in automotive seals, gaskets, O-rings, hoses, and fuel system components.

4.Ethylene propylene diene monomer (EPDM)

- EPDM is a synthetic rubber known for its exceptional weather resistance and UV stability.

- It offers excellent ozone resistance, heat resistance, and electrical insulation properties.

- EPDM is commonly used in automotive weather seals, roofing membranes, electrical insulation, and outdoor gaskets.

5.Neoprene (CR):

- Neoprene is a synthetic rubber known for its excellent resistance to oil, ozone, weathering, and abrasion.

- It offers good flexibility, resilience, and flame resistance, making it suitable for a wide range of applications.

- Neoprene is commonly used in automotive hoses, gaskets, seals, wetsuits, and industrial belting.

Materials Guide

6.Silicone rubber (VMQ):

- Silicone rubber offers excellent heat resistance, cold flexibility, and biocompatibility.

- It has good electrical insulation properties, low chemical reactivity, and resistance to UV radiation and ozone.

- Silicone rubber is commonly used in medical devices, automotive seals, gaskets, cooking utensils, and electronics components.

7.Fluoroelastomers (FKM/Viton)

- Fluoroelastomers are synthetic rubbers known for their exceptional chemical resistance, high temperature resistance, and resistance to fuels and oils.

- They are commonly used in demanding applications requiring resistance to aggressive chemicals, high temperatures, and harsh environments, such as seals, O-rings, gaskets, and diaphragms in aerospace, automotive, and chemical processing industries.

8.Polyurethane (PU)

- Polyurethane elastomers offer high abrasion resistance, tear strength, and load-bearing capacity.

- They exhibit good flexibility, resilience, and chemical resistance, making them suitable for demanding applications.

- Polyurethane is commonly used in industrial seals, rollers, bushings, wheels, and hydraulic seals.

9.Butyl rubber (IIR)

- Butyl rubber offers excellent impermeability to gases, making it ideal for applications requiring air or gas retention.

- It has good weather resistance, electrical insulation properties, and damping characteristics.

- Butyl rubber is commonly used in tire inner tubes, pharmaceutical stoppers, inflatable seals, and roofing membranes.

10.Chloroprene rubber (CR/Neoprene)

- Chloroprene rubber, commonly known as Neoprene, offers good resistance to oil, ozone, weathering, and flame.

- It exhibits good mechanical properties, including flexibility, resilience, and tear resistance.

- Neoprene is commonly used in automotive seals, gaskets, hoses, wetsuits, and industrial belting.

These are some of the most common rubber molding materials, each offering unique properties suited to specific applications across various industries. Choosing the right material is crucial to ensure optimal performance, longevity, and reliability of rubber-molded components.

Inspection standards for rubber products

Some common inspection criteria include:

1.Appearance inspection

During the vulcanization process, the initial molded parts of each work shift undergo appearance inspection, while 100% of finished parts undergo appearance inspection during acceptance.

Visual inspection is generally used as the method for appearance inspection.

When inspecting the surface finish of parts, the standard specified on the mold drawing is generally used as the criterion.

2.Dimension inspection

The vulcanization process undergoes initial mold inspection; finished product acceptance generally involves sampling inspection. However, for parts with strict dimensional requirements or requiring machining, as well as parts needing stable treatment in working media, the main dimensions should ideally undergo 100% inspection.

Parts that have undergone vulcanization and deburring should be left for 6 hours before undergoing dimension inspection. Rubber parts have significant elastic deformation, and improper selection of measurement methods or instruments can affect measurement accuracy. Generally, trial mold identification and trial production should use general-purpose measuring tools and instruments, while mass production should use special-purpose measuring tools.

3.Performance testing

a) Shore A hardness test: The sample thickness should be no less than 6mm, width no less than 15mm, and length no less than 40mm. If the thickness requirement is not met, the same sample can be overlapped for measurement, but not more than four layers, and the upper and lower surfaces should be parallel.

b) Oil resistance test: The sample is immersed in oil, acid, alkali, or other liquid media, and changes in dimensions, volume, or weight are measured after a specified time at the prescribed temperature.

c) Rubber-metal bonding strength test: Peel method. Generally, a ?3 steel needle is used to pick the rubber on the metal part. If there are uniform rubber bonding traces on the surface of the metal part after the rubber is picked and fractured, the bonding strength is considered qualified. For each set of parts in each work shift, 1-3 parts are generally sampled for bonding strength testing during initial mold inspection and finished product acceptance.

Boyi provides high-quality rubber molding services

Boyi provides rubber molding services. We have advanced technology and equipment, including compression molding and injection molding, to meet the needs of our customers. Our team consists of experienced engineers and technical experts who can custom design a variety of complex rubber parts for customers. We are committed to providing customers with high-quality, high-precision molded parts and customizing them according to their specific requirements. If you need rubber molding services, please contact us, and we will be happy to assist you.

Put your parts into production today

All uploads are secure and confidential.

Conclusion

Injection molding offers efficiency and precision for high-volume production of complex parts. Compression molding is well-suited for medium-volume production with consistent dimensions. Transfer molding provides precise material control for small or intricate parts. Each of these molding processes has its advantages and is suited to different applications based on factors such as part complexity, production volume, and material properties.

FAQ – Rubber molding

Rubber molding shapes rubber materials using heat and pressure, producing items like seals and gaskets, while plastic molding shapes plastic resins into desired forms through heating and cooling processes, used in various industries for consumer goods, packaging, and automotive parts.

Rubber molding is a manufacturing process for producing rubber products, typically involving the following steps: First, the rubber is heated to a certain temperature to make it soft and pliable for processing. Then, the heated rubber is placed into a mold, the shape and size of which determine the final product’s shape. Pressure is applied to ensure that the rubber fills every detail and corner of the mold completely. Once the rubber cools and solidifies, the finished product can be removed from the mold. This method is used to manufacture various rubber products such as seals, gaskets, and fittings.