In precision plastic manufacturing processes, even minor defects can have significant implications for the performance and quality of the final product. Plastic injection molding, as a widely used molding technique, presents jetting defects during its process that manufacturers need to pay close attention to.

This article will delve into the causes of jetting defects and propose corresponding avoidance strategies to assist injection molding companies in enhancing product quality and reducing defect rates.

Please continue reading for all the information regarding jetting in injection molding.

Identifying Jetting in Injection Molding

Jetting defects in injection molding are caused by uneven solidification processes. This occurs when the resin stream begins to solidify before the mold cavity is fully filled.

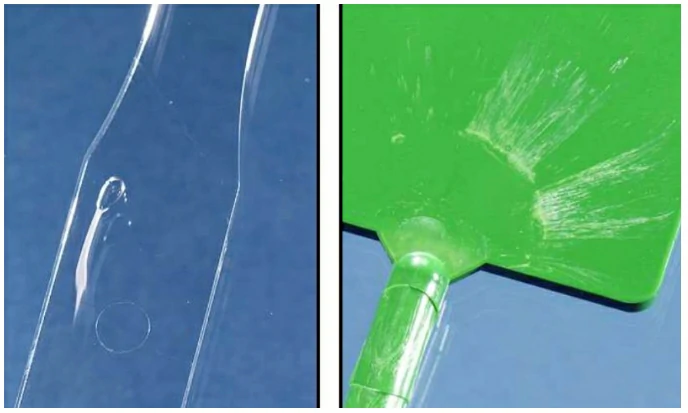

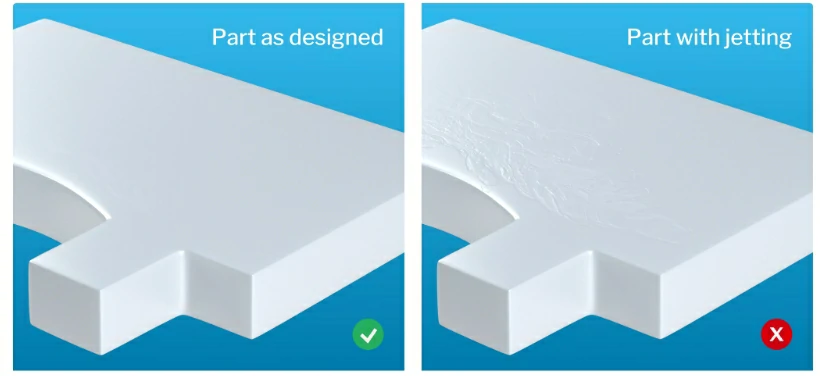

Jetting manifests as a “snake-like” or wavy pattern on the surface of the molded part, often originating from the gate area, known as jetting or “worm tracks,” as depicted in the following diagram.To avoid jetting, it’s important to optimize the gate design, adjust the injection parameters, ensure proper mold temperature, and choose suitable plastic materials.

Cause and Avoidance Strategies for Jetting in Injection Molding

In injection molding, jetting not only affects the appearance quality of the product, but more importantly, it may also compromise the strength and other mechanical properties of the parts.

Here is an analysis of the causes of jetting defects and corresponding avoidance strategies:

Runner Location and Design Are Problematic

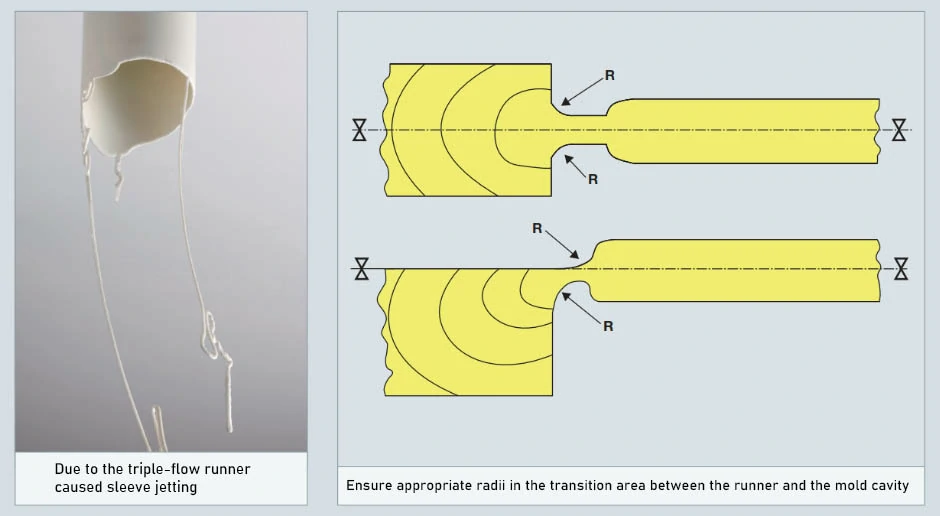

If the runner is positioned too close to the edge or corner of the mold, the melt may rapidly spread during flow due to lack of support, resulting in jetting. Additionally, an improper runner design, such as a too small cross-section or obstructions within the runner, can also lead to poor melt flow and jetting.

Avoidance Strategies

Optimize runner design and positioning.

Adjust the runner position so that the ejected polymer melt immediately encounters obstacles outside the runner. To achieve more stable melt flow, consider relocating the runner to the center of the mold or closer to the solid regions of the product.

Enlarge the cross-sectional area of the runner. Increasing the cross-sectional area of the runner reduces resistance to melt flow, allowing the melt to flow more smoothly.

Ensure smooth transition zones. Avoid sharp corners between the runner and the mold.

Gate Location and Design Are Problematic

The size of the gate directly affects the flow of molten plastic in the mold. A smaller gate size may result in poor melt flow and the occurrence of jetting. Additionally, improper gate positioning can also lead to jetting during the melt flow process.

Avoidance Strategies

Adopting a fan-shaped or angled gate design, selecting short and wide gates, or increasing the cross-sectional area of the gate can reduce the flow velocity of the molten material, enabling it to flow more stably and avoiding jetting.

Positioning the gate where the resin can quickly contact the inner walls of the mold: This ensures rapid contact between the melt and the mold walls during flow, reducing its velocity and minimizing the risk of jetting.

Additionally, a similar effect can be achieved by placing pins or walls within the mold cavity to impede resin flow.

Mold Design is Improper

The jetting issue resulting from improper mold design for plastic processing (e.g., abrupt changes in wall thickness along the flow path). These abrupt changes in wall thickness can also cause surface sink marks, affecting the appearance quality of the product.

Avoidance Strategies

Modify the mold design to avoid abrupt changes in wall thickness.

If the mold design must include areas with different wall thicknesses, ensure there are transition zones at the points of thickness variation. These transition zones can be designed with gradients to gradually transition from thicker to thinner sections, thereby reducing the generation of internal stresses and the risk of jetting.

Alternatively, utilizing computer-aided engineering (CAE) simulation tools can help designers predict and optimize the flow and solidification processes of the model. Through simulation, potential jetting areas can be identified, and the model design can be adjusted accordingly to minimize jetting occurrences.

Injection Speed is Too High

When the injection speed is too high, the molten material undergoes jetting. Due to the elasticity of the molten material, rapid flow from the barrel through the mold gate to the cavity can result in overly quick elastic recovery, causing molten material rupture and the formation of radial streaks.

Avoidance Strategies

To mitigate this, reduce the injection speed by adjusting the switch to a lower position. Alternatively, adding a throttle valve to the inlet and outlet pipelines of the injection machine can help control the flow rate and pressure of the molten material, thereby reducing the injection speed.

Implementing multi-stage injection: slow to fast. For example, slowing down the injection speed when the molten plastic first passes through the gate, using high-speed injection during the filling process, and then slowing down again at the end of filling.

Plastic is Cooling Too Quickly

Plastic cooling too quickly in the mold leads to jetting. When plastic cools too rapidly within the mold, the molten material may suddenly solidify during injection due to decreased flowability, resulting in jetting or other molding defects.

Avoidance Strategies

To mitigate this issue, the mold temperature can be increased by heating the mold or using hot runner technology, thereby slowing down the cooling rate of the plastic. Alternatively, adjusting the mold temperature directly can control the cooling rate.

Different plastics have different melt indices and cooling indices. Choosing plastics with lower cooling indices can slow down the cooling rate, thus reducing the risk of jetting.

Conclusion

To address the issue of jetting in injection-molded parts, it’s essential to consider multiple factors such as mold design and injection molding process parameters. Through reasonable adjustments and optimizations, the occurrence of jetting can be effectively reduced, thus improving the quality and performance of the products.

Do you have any further questions? Feel free to contact us at BOYI to connect with our expert manufacturers. Alternatively, you can check out our blog post “15 Common Types of Injection Molding Defects, Causes, Remedies” for more information on injection molding defects.

Avoiding these and other injection molding defects hinges on using the right mold manufacturer. Every detail is crucial, especially in the pursuit of superior product quality. Warping, short shot, flash, weld lines… These common injection molding defects not only affect the appearance of the product but may also compromise its performance.

As your trusted injection molding solution expert, BOYI is committed to helping you overcome these challenges and achieve a leap in product quality. With our skilled technical team and extensive industry experience, we strive to provide you with top-notch mold design and injection molding solutions.

Contact us now to kickstart your injection molding project.

Put your parts into production today

All uploads are secure and confidential.

FAQ

Jetting occurs when molten plastic exits a narrow or poorly positioned gate in the mold at a high velocity, causing uncontrolled spraying. Proper gate design and placement are key to preventing jetting.

Jetting can be characterized as an undesirable “snake-like” pattern visible on the surface of an injection molded part, typically originating from the gate area.

To avoid jetting in injection molding, optimize gate design, adjust injection speed and pressure, ensure adequate mold heating, and use materials with good flow properties.

Tagged: Injection Molding Guide