Nuts and bolts are common fasteners in the manufacturing industry, serving the purpose of mechanically connecting two or more components together. For instance, when installing equipment, screws are used to secure various objects. Many people are not clear about the differences between bolts and nuts. Some believe that bolts are nuts, and nuts are bolts. However, this misconception is incorrect. In this CNC machining guide, we will delve into the distinctions between bolts and nuts, as well as the types they come in.

What is a nut?

A nut, also known as a nut cap, consists of a square or hexagonal block with an internal threaded hole. It is a component used for fastening when screwed together with a bolt or screw, and it is an essential element for all manufacturing machinery.

When a bolt is threaded into a nut, the friction between the threads prevents them from coming apart. The magnitude of this friction depends on the geometric shape of the threads, material hardness, and the degree to which the bolt is tightened. As the bolt is further tightened, it undergoes slight elongation, while the connected components and the nut are compressed, resulting in increased friction, further ensuring the stability of the connection.

It’s important to note that even when using a nut as a fastening device, it is necessary to use nuts and bolts of equal specifications to connect together. For example, an M4-P0.7 nut can only be connected with an M4-P0.7 series bolt (in the case of nuts, M4 refers to an inner diameter of approximately 4mm, and 0.7 refers to the distance between two thread crests being approximately 0.7mm); the same principle applies to imperial units, for instance, a 1/4-20 nut can only be paired with a 1/4-20 bolt (1/4 indicating an inner diameter of approximately 0.25 inches, and 20 indicating 20 threads per inch).

Types of nut

There is a wide variety of nut types, each with its specific uses and advantages. However, regardless of the type, the vast majority of nuts are hexagonal because the six sides allow the nut to be easily gripped and turned by a wrench, screwdriver, or similar tool. Each rotation of one-sixth of a circle allows the nut to reach the next parallel plane, making the fastening and loosening process quick and straightforward. Some of the most common types of nuts include:

1.Acorn nuts

Acorn nuts, as the name suggests, are nuts with caps, named for the acorn-shaped cap at the top. Their primary purpose is to prevent foreign particles and moisture from infiltrating the interior, thus avoiding corrosion and rust. They also serve to minimize the risk of skin and clothing catching on sharp edges. Therefore, these nuts are often used in industrial machinery in areas where contact with the human body is frequent, reducing the risk of injury to personnel.

2.Weld nuts

Weld nuts are nuts designed to be welded onto another component. They are typically made of weldable materials and have a thicker structure to accommodate the welding process. Weld nuts create a strong connection by fusing the two separate pieces into one solid unit through high temperatures.

Weld nuts find widespread use in applications requiring high-strength connections, such as in construction, bridges, vehicle manufacturing, and other fields. They are welded into place to provide sturdy support and connection at their respective positions.

3.Hex nuts

Hex nuts are named for their hexagonal shape, featuring six equal sides and angles. This design allows them to be easily tightened or loosened using tools such as wrenches or screwdrivers. Hex nuts are suitable for fastening most mechanical components and equipment, capable of withstanding high pressures without deformation or damage.

4.Wing nuts

Wing nuts feature a wing-shaped structure with wings on each side of the nut, allowing them to be easily rotated by hand without the need for tools. This makes them particularly suitable for use on equipment that requires frequent disassembly or fastening. Their design enables quick and convenient operation.

Wing nuts are commonly used in mechanical equipment, electrical equipment, transportation vehicles, and other applications where frequent tightening or loosening of nuts is necessary. They are the perfect solution for situations requiring frequent adjustment or removal of nuts.

5.Barrel nuts

Barrel nuts, also known as sex bolts or Chicago screws, are made of steel and feature extremely thin bolt heads and metal parts. Their advantage lies in not requiring flanges to be machined or forged on the receiving component, thus reducing their weight.

6.Jam nuts

Jam nuts are highly practical fasteners, typically hexagonal in shape and half the size of regular nuts. They come in various designs and structures, including but not limited to friction locking, mechanical locking, rivet locking, and structural locking methods.

In mechanical and engineering applications, the problem of nuts loosening due to vibration or impact is often encountered. The introduction of jam nuts effectively addresses this issue. For example, In automotive fasteners, jam nuts are primarily used as fasteners for critical components such as automotive suspension, engines, and transmissions to prevent loosening caused by vibration and impact.

7.Lock nuts

Lock nuts utilize friction between the nut and bolt to self-lock, ensuring the stability of the connection. In some critical applications, additional anti-loosening measures may be taken to ensure the reliability of nut locking. Refer to the “jam nuts” mentioned above.

Lock nuts are widely used in industries such as machinery to secure threaded pipe fittings or other components, ensuring stable and safe connections.

8.Flange nuts

Flange nuts, also known as flanged nuts, washer-faced nuts, serrated flange nuts, or hex flange nuts, feature a wide flange at one end, which effectively acts as an integrated washer. When the nut is tightened, this flange distributes pressure evenly across the secured component, reducing the risk of damage due to excessive pressure and increasing the stability of the entire connection.

Put your parts into production today

All uploads are secure and confidential.

What is a bolts?

A bolt is a type of fastener consisting of a head and a threaded cylindrical shaft (with external threads). It is designed to be used in conjunction with a nut to securely fasten two components with through-holes. This type of connection is known as bolted connection. By unscrewing the nut from the bolt, the two components can be separated, making bolted connections detachable.

Unlike screws, bolts require pre-made internal threads to engage with nuts; they are not self-threading. Screws, on the other hand, may have their own internal threads (such as self-tapping screws) or may rely on their external threads to be screwed directly into pre-made holes in the components being connected.

Types of bolts

There are various types of bolts that can be classified according to different standards and requirements. The following are some common types of bolts:

1.Anchor bolts

Anchor bolts are commonly used in the construction industry. They utilize the structure of the bolt itself, combined with special components, to expand and anchor in concrete foundations within bolt holes. This type of bolt is convenient to install on-site and can immediately bear loads once installed. Moreover, they can be disassembled and reused if necessary, making them popular among professionals and DIY enthusiasts alike.

2.Carriage bolts

Carriage bolts consist of a head and a cylindrical shaft with external threads, making them fasteners that require use with nuts to securely connect two components with through-holes. Their heads are often hexagonal and relatively large, with a rounded shape and no designs such as cross-slots or internal hexagons. This design not only facilitates installation but also serves as a deterrent against theft during the connection process.

3.Blind bolts

Blind bolts are a special type of bolt characterized by their non-through-hole design. They typically feature internal hexagon and internal hexagon with grip slot structures, facilitating installation using hexagon wrenches or socket heads. This design makes blind bolts particularly useful in situations where tightening can only be done from one side.

Blind bolts exhibit high strength. For example, a blind bolt with an M20 specification can have a shear load-carrying capacity design value of up to 54.5 kN (single shear surface), and the tensile load-carrying capacity design value varies depending on the type of blind bolt but generally remains high. This strength ensures that blind bolts can provide stable and reliable connections in various applications.

4.U-bolts

U-bolts, also known as horse bolts, are named for their unique U-shaped structure. These bolts are non-standard components. They feature threads at both ends of the U shape, which can be combined with nuts to achieve fastening. U-bolts are primarily used for securing cylindrical objects such as pipes or flat objects like vehicle leaf springs.

5.Eye bolts

Eye bolt is a type of bolt with a lifting eye on the head, characterized by a longer shaft and fewer threads. It consists of three parts: the lifting eye, nut, and bolt. Usually used for lifting or hanging heavy objects, such as outdoor fences, tower cranes, and other scenarios.

During installation, the lifting eye bolts must be installed vertically on the plane of the workpiece, the joint surface should be flat and tight, and adjusted to the stretching direction to avoid contact with sharp edges. Its test load is 2.5 times the working load, and 20000 fatigue tests are conducted at 1.5 times the working load.

6.Hex bolts

Hex bolts are one of the most commonly used types of bolts. Their surfaces are hexagonal in shape, allowing for rotation using tools such as wrenches to apply the necessary force for fastening. Regarding the threaded portion, hex bolts can be fully threaded or partially threaded. They are suitable for connecting various mechanical equipment and structures.

7.Flange bolts

Flange bolts primarily consist of three parts: a hexagonal head, a flange (which includes a washer and is integrated with the hexagon below), and a shaft (a cylindrical body with external threads). The flange serves as a washer, distributing the load and providing a larger “support area to stress area ratio” for the bolt.

The working principle of flange bolts mainly relies on the mutual engagement of the threads. When the nut is rotated, the threads between the bolt and the nut interlock, causing the bolt to move forward or backward, achieving the fastening effect. Compared to regular bolts, flange bolts have wider heads and usually have expanded tails, making them more sturdy and secure.

Flange bolts are widely used in scenarios requiring the bearing of heavy loads and higher safety, such as automotive engines and heavy machinery products.

Put your parts into production today

All uploads are secure and confidential.

How to choose the appropriate nut for your bolt?

Selecting the appropriate nut for a bolt is a process that requires considering multiple factors. Below are some key steps and factors to consider:

1.Match thread specifications

Ensure that the chosen nut’s thread specifications match those of the bolt completely. This includes parameters such as nominal diameter, pitch, and thread count. For example, an M6 bolt should correspond to an M6 nut. If the specifications don’t match, the nut won’t properly install on the bolt, affecting the fastening effect.

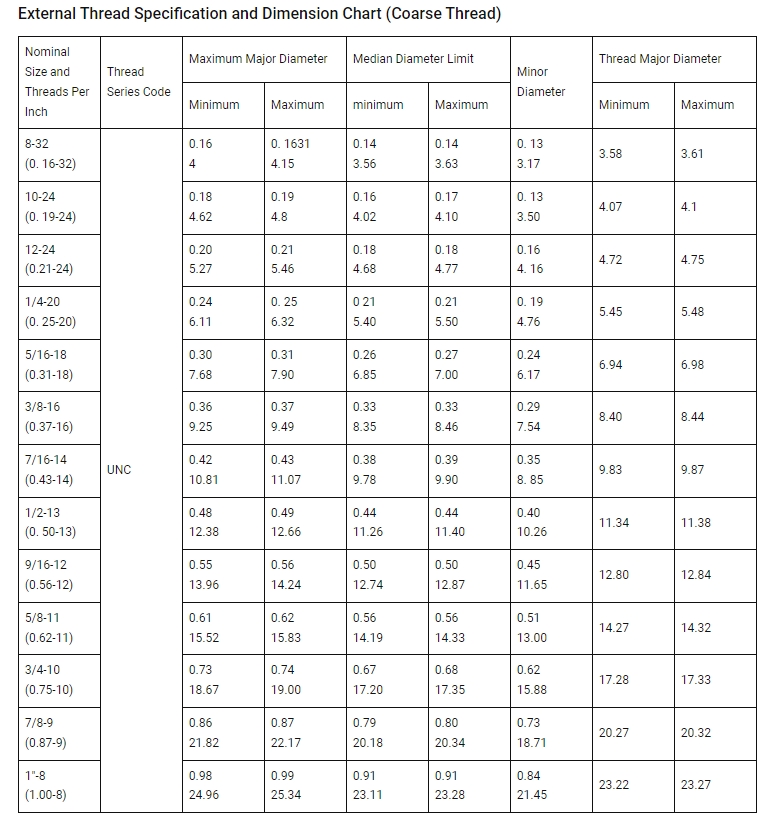

For more thread specifications and sizes, please refer to the following article:

Thread Size Chart (inch/mm)

2.Size and shape

Choose the appropriate nut size and shape based on the usage scenario and requirements. For instance, the selection of head type may involve factors such as anti-tamper performance, appearance, and stability. If a stable and secure nut is needed, consider using a prevailing torque nut or a nut with washers.

3.Determine required strength

Select the nut material and grade based on the strength requirements of the application. For instance, for applications requiring high loads, opt for high-strength nuts.

4.Consider environmental conditions

If the nut will be used in damp, corrosive, or high-temperature environments, choose a nut with corresponding corrosion resistance and high-temperature characteristics. Stainless steel nuts are typically suitable for these special environments.

5.Choose the appropriate nut type

Select the appropriate nut type based on specific needs. For instance, if better anti-tamper performance is required, consider using a hex flange nut; if higher strength is needed, opt for a prevailing torque nut, etc.

Common bolt and nut materials

The commonly used materials for bolts and nuts include:

- Carbon steel

- Stainless steel

- Alloy steel

- Aluminum alloy

- Titanium alloy

- Brass

- Polymers, such as nylon

What is the difference between nuts and bolts?

Nuts and bolts are reliably connected through threaded structures. Although they are functionally similar, there are various differences between nuts and bolts. The following chart summarizes these differences:

Nut vs bolt chart

| Feature | Nut | Bolt |

|---|---|---|

| Purpose | Provides the opposite side of the threaded hole to secure the bolt to the component | Passes through the component and engages with a nut to form the connection |

| Shape | Typically hexagonal or square | Mostly cylindrical |

| Structure | Hollow | Solid |

| Function | Provides the threaded hole for the bolt to be screwed into | Provides torque to screw into the nut |

| Material | Usually metal | Usually metal |

| Fastening method | Matches with the bolt by rotation | Matches with the nut by rotation |

| Size | Size usually determined by thread specifications | Size usually determined by diameter and length |

| Primary role | Provides threaded hole allowing bolt fixation | Provides torque and force for a secure connection |

| Common types | Standard, hexagonal, square | Flat head, round head, screw type, stud type |

Summary

In summary, nuts and bolts have their own characteristics in function, structure, and use, and they work together to achieve the fastening of mechanical connectors. In practical applications, it is necessary to select appropriate types, specifications, and materials of nuts and bolts based on specific connection requirements and environmental conditions.

Boyi, as a professional provider of CNC machining services, possesses advanced equipment and a skilled team capable of delivering high-quality, high-precision fasteners to customers. Feel free to contact Boyi anytime for detailed consultations and expert advice.

Put your parts into production today

All uploads are secure and confidential.

FAQ

The bolt might be stronger than the nut, especially if it’s made from a higher grade or stronger material. However, in a properly designed and assembled fastening system, both the nut and the bolt should be appropriately matched in strength to ensure the overall integrity of the joint.

Torque bolts instead of nuts for better control and consistency in tightening, ensuring uniform clamping force and reducing the risk of over-tightening or stripping threads.

Bolts are typically used for heavy-duty applications where high strength and load-bearing capacity are needed, such as in construction, machinery, and automotive assemblies. Screws are often used for lighter-duty applications or where the joint needs to be disassembled more frequently, such as in furniture assembly, electronics, and woodworking.