8020 aluminum, as a special type of aluminum alloy material, is widely used in industrial and construction fields due to its unique T-shaped groove design and extrusion processing technology. This article will explore the characteristics, applications, and advantages of 8020 aluminum.

Why is it called 8020 aluminum?

8020 aluminum, also known as 80/20 extruded aluminum or 80/20 framing, “8020” , which is the ratio of 80% aluminum to 20% other alloying elements. This ratio gives it excellent strength and corrosion resistance, while maintaining its relatively lightweight characteristics.

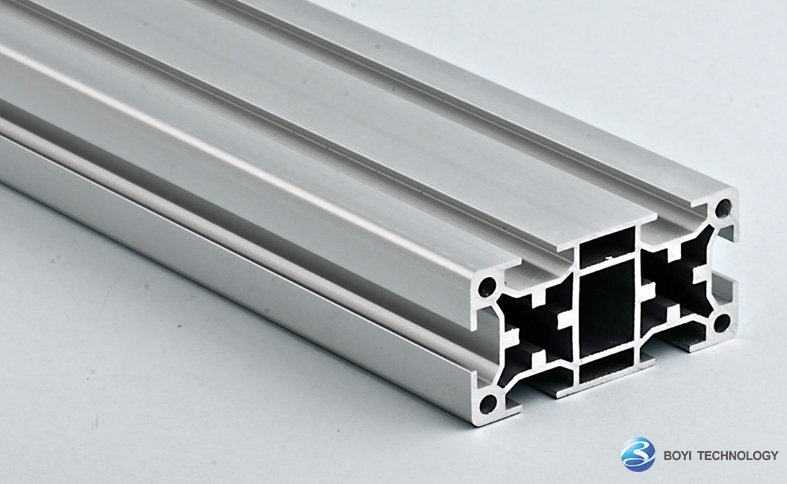

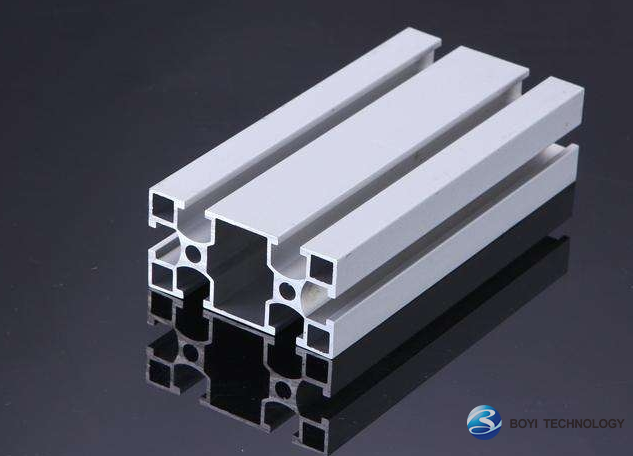

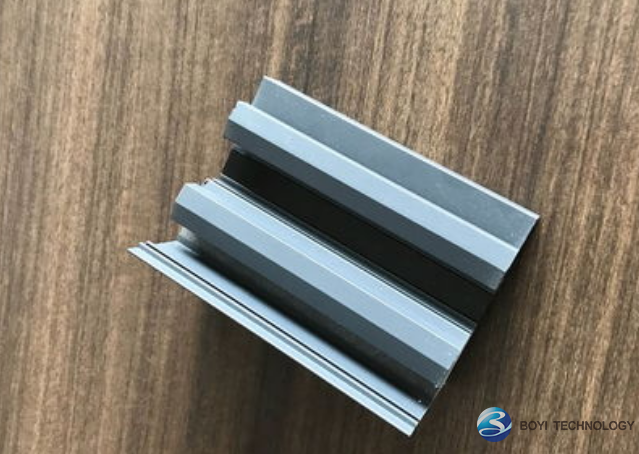

When constructing the 8020 aluminum extrusion T-groove frame, users usually choose a series of prefabricated aluminum profiles with different lengths, cross-sectional shapes, and sizes. Then, they use these profiles and T-groove accessories (such as nuts, bolts, angle brackets, etc.) to assemble the required framework. The advantages of this system lie in its ease of use, durability, and reusability.

Where does the name 80/20 come from?

The name “80/20” for the extruded aluminum stock and the company 80/20, Inc. is indeed derived from Pareto’s Law, which states that a small proportion of inputs often produces a disproportionately large result or output. The choice of this name reflects the manufacturer’s commitment to providing a product that is highly efficient and effective, with a focus on optimizing the use of materials and effort.

80/20, Inc. was founded in 1989 and named after the economic principle to emphasize the company’s dedication to creating aluminum extrusions that offer maximum performance and value. The company’s products are designed to provide strong, lightweight, and cost-effective solutions for a wide range of applications, from industrial automation to consumer products.

By naming their products and company after Pareto’s Law, 80/20, Inc. is symbolically expressing their belief that a small percentage of their efforts (the 20%) will yield the majority of the benefits (the 80%) for their customers. This naming convention has become synonymous with the company and its products, making “80/20” a recognizable brand name in the aluminum extrusion industry.

How strong is 8020 aluminum extrusion?

The strength of 8020 aluminum extrusion is primarily determined by the alloy composition, tempering process, and geometrical characteristics of the extruded profiles. Aluminum alloys commonly utilized in 8020 extrusions, such as 6061 and 6063, are renowned for their excellent mechanical properties, including high tensile strength and yield strength.

The strength of 8020 aluminum extrusion can be further augmented through appropriate heat treatment methods, such as solution heat treatment followed by quenching and aging. These processes refine the microstructure of the alloy, enhancing its mechanical properties and overall strength.

The design of the extruded profile also plays a critical role in determining its strength characteristics. Factors such as wall thickness, cross-sectional geometry, and the presence of reinforcing features influence the structural integrity and load-bearing capacity of the extrusion.

8020 aluminum t-slot profile technical specifications

- Yield Strength:

- Fractional: 35,000 p.s.i. (minimum)

- Metric: 241.1 N/mm² (minimum)

- Tensile Strength:

- Fractional: 38,000 p.s.i. (minimum)

- Metric: 262.0 N/mm² (minimum)

- Elongation:

- A5 minimum: 10%

- A10 minimum: 8%

- Elasticity (E):

- 10,200 k lb/in²

- 70,326.5 N/m²

- Hardness:

- Rockwell approximately E-88

- Brinell approximately 75 HB

- Flatness:

- 0.004 inches per 1 inch of width

- 0.1mm per 25.4mm of width

- Straightness:

- 0.0125 inches per 1 foot of length, not to exceed 0.118 inches over 20 feet of length

- 0.32mm per 304mm of length, not to exceed 3mm over 6.1m of length

- Twist:

- Per 1 foot of length, not to exceed 0.25 degree, and total twist over 20 feet of length not to exceed 1.5 degrees

- Per 304mm of length, not to exceed 0.25 degree, and total twist over 6.1m of length not to exceed 1.5 degrees

Note: Engineers judiciously harness analytical methodologies, including finite element analysis (FEA), computational fluid dynamics (CFD), and multivariate optimization techniques, to meticulously evaluate the mechanical behavior of 8020 aluminum extrusions. Experimental validation through rigorous testing protocols such as tensile testing, flexural testing, and fatigue testing corroborates theoretical predictions and ascertains conformity with stringent industry standards and specifications.

8020 aluminum extrusion applications

8020 aluminum (or 80/20 aluminum) is very versatile, mainly due to its high strength, light weight, good corrosion resistance, easy processing and modular design. Here are some common uses of 8020 aluminum:

1.Material handling systems

T-slot profiles are employed in the creation of material handling systems such as conveyors, racks, carts, and shelving units. Their modular design enables the customization of these systems to fit specific requirements, optimizing workflow efficiency in warehouses and distribution centers.

2.DIY projects and hobbyist applications

Hobbyists and DIY enthusiasts utilize 8020 aluminum extrusions for a wide range of projects, including building workbenches, storage solutions, CNC machines, 3D printers, and custom furniture. The ease of assembly and endless configuration possibilities make T-slot profiles popular among hobbyists.

3.Retail fixtures and displays

In the retail sector, T-slot profiles are utilized to fabricate fixtures, displays, and signage. These structures offer a sleek and modern aesthetic while providing the flexibility to adapt to changing merchandising needs.

4.Industrial workstations

8020 aluminum extrusions are extensively used to construct custom industrial workstations, assembly lines, and manufacturing cells. These workstations provide flexibility in layout design, adaptability to changing production needs, and durability in industrial environments.

5.Machine frames and enclosures

The robustness and lightweight nature of 8020 aluminum extrusions make them ideal for constructing machine frames, enclosures, and guarding systems. These structures provide protection to machinery and operators while allowing easy access for maintenance and repair.

The advantages and disadvantages of 8020 aluminum

8020 aluminum has the following advantages and disadvantages:

8020 aluminum advantages:

Modular design: The 8020 aluminum system has a modular design that makes setup and disassembly easy and fast. Users can easily add different parts and components to, or remove from, the framework without the need for complex tools or technologies.

High strength and lightweight: Aluminum alloy has high strength and lightweight characteristics, making the 8020 aluminum frame both strong and lightweight. This makes it very popular in applications that require high strength support but require weight reduction.

Good corrosion resistance: Aluminum alloys have good corrosion resistance to most environmental conditions, which allows the 8020 aluminum frame to be used in a variety of environments without the need for additional anti-corrosion treatment.

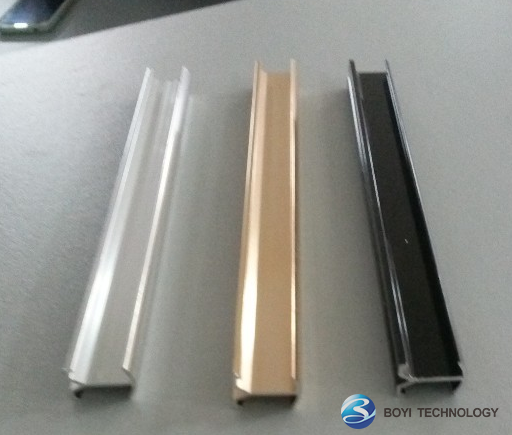

Easy to process and customize: Aluminum alloys are easy to process and customize through extrusion, cutting, drilling and tapping processes to meet specific application needs.

Good electromagnetic shielding performance: The 8020 aluminum frame can provide good electromagnetic shielding effect, which is very important in electronic devices and other applications that require electromagnetic shielding.

Recyclable reuse: Aluminum alloy is a recyclable material that meets the requirements of environmental protection and sustainable development.

8020 aluminum disadvantages:

Higher cost: The cost of aluminum alloys can be higher compared to some other materials, especially when mass production is required.

Electrical conductivity: Although aluminum alloys have good electrical conductivity, in some applications, this can become a drawback. For example, in applications where electrical isolation is required, aluminum alloys may require additional insulating treatment.

Sensitivity to the environment: Although the aluminum alloy itself has good corrosion resistance to most environmental conditions, it may be affected under certain extreme environmental conditions (such as high humidity, high salinity, etc.).

Limited strength and stiffness: Although aluminum alloy has high strength and stiffness, it may not be the best choice in some applications that require extremely high strength and stiffness.

What is the difference between extruded aluminum T-slot and V-slot?

Extruded aluminum T-slot and V-slot are two different types of profiles commonly used in modular framing systems. They differ primarily in their cross-sectional shape and how they are designed to work with components and accessories.

T-Slot aluminum extrusion:

T-slot aluminum extrusions have a cross-sectional shape that resembles a letter “T.” This shape creates a track or slot that runs along the length of the extrusion, allowing for the insertion of T-nuts or other compatible fasteners. These fasteners can then be tightened to securely hold components in place within the frame.

T-slot aluminum extrusions are popular in industrial applications because they offer a strong and rigid structure that can be easily customized. The T-slot design allows for quick and easy assembly, disassembly, and modification of frames. It is also compatible with a wide range of accessories, brackets, and connectors, making it a versatile framing solution.

V-Slot aluminum extrusion:

V-slot aluminum extrusions have a cross-sectional shape that resembles a letter “V.” This design creates a groove or slot that runs along the length of the extrusion, allowing for the insertion of compatible components, such as clamps or brackets, without the need for fasteners.

V-slot aluminum extrusions are becoming increasingly popular in robotics, automation, and other DIY applications. They offer a lighter and more cost-effective framing solution compared to T-slot extrusions. The V-slot design allows for quick and easy assembly of frames without the need for tools or fasteners, making it suitable for hobbyists and DIY enthusiasts. However, it may not offer the same level of strength and rigidity as T-slot extrusions.

What are the other types of aluminum materials?

There are many types of aluminum materials, and in addition to the aforementioned 8020 aluminum, there are other types of aluminum materials. The following are some common types of aluminum materials:

Industrial Aluminum Profiles:

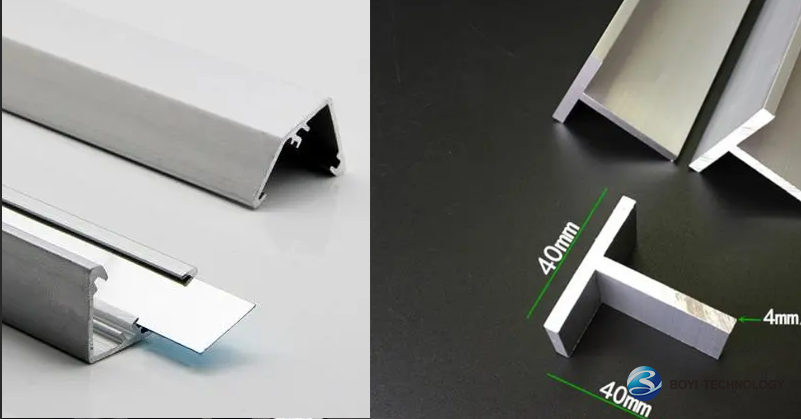

- Angle Aluminum: Aluminum with an angular cross-section, commonly used for connections and support structures.

- Flat Aluminum: Flat aluminum sheets used for various panels, housings, and decorative purposes.

- Hexagonal Aluminum, Round Tubular Aluminum, Square Tubular Aluminum: Aluminum with different cross-sectional shapes, used for various structural and mechanical components.

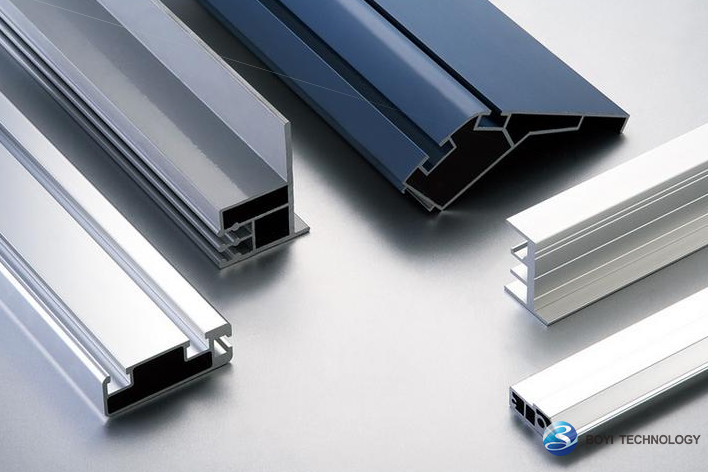

Architectural Aluminum Profiles:

- Door and Window Profiles: Aluminum framing materials for architectural doors and windows.

- Curtain Wall Profiles: Aluminum support and connection materials for architectural curtain walls.

- Aluminum Alloy Sheet Materials: Aluminum sheets used for exterior walls, roofs, and interior decoration of buildings.

Decorative Aluminum Profiles:

- Aluminum Alloy Picture Frames: Aluminum frames for framing various exhibitions and decorative paintings.

- Decorative Strips: Long aluminum strips used for decorating and beautifying the exterior of buildings.

Transportation Aluminum Profiles:

- Aluminum Profiles for Railway Vehicle Structures: Aluminum structural materials used for the manufacturing of railway vehicle bodies.

- Automotive Aluminum Profiles: Aluminum materials used for car bodies, chassis, engines, and other parts.

Electronic Aluminum Profiles:

- Radiator Aluminum Profiles: Aluminum materials used for heat dissipation in electronic devices.

- Aluminum Alloy Extruded Tubes: Aluminum tubes used for electronic device housings and internal structures.

Aluminum Profiles Classified by Alloy Composition:

- 1-series Aluminum: Such as 1050, 1060, etc., mainly used in food, packaging, and chemical industries.

- 3-series Aluminum: Such as 3003, 3105, etc., mainly used in packaging, construction, and partition housing.

- 5-series Aluminum: Such as 5052, 5083, etc., with high strength and corrosion resistance, mainly used in ships, pressure vessels, and high-strength welding structures.

- 6-series Aluminum: Such as 6061, 6063, etc., are the most common aluminum alloys and are used in various construction and industrial applications.

- 7-series Aluminum: Such as 7075, etc., with extremely high strength and hardness, mainly used in aerospace and military fields.

In addition, aluminum diamond plate can also be classified under these alloy categories, typically seen in applications requiring durable and slip-resistant surfaces such as truck beds, stair treads, and industrial flooring.

The above are only some types of aluminum materials, and in fact, the types and applications of aluminum materials are very extensive, covering almost all industries.

Need a high quality 8020 aluminum extrusion service? Give us a call.

Are you looking for a company that can provide high quality 8020 aluminum extrusion service? Then, Boyi is your best choice!

We have advanced extrusion equipment and exquisite process technology to ensure that every product meets the highest standards. Whether you need a customized aluminum solution or want to optimize your existing production process, I have a one-stop service for you. From design to production to installation, I am involved to ensure that every detail is flawless. Contact us now!

Put your parts into production today

All uploads are secure and confidential.

FAQ

The 80/20 framing system was invented by 80/20 Inc., a company founded in 1989 by Don Wood and Bob Kyanka. They introduced the concept of using T-slot aluminum extrusions with a modular design, allowing users to easily assemble and reconfigure structures without the need for welding or specialized tools. Since its introduction, the 80/20 framing system has gained widespread popularity due to its versatility, durability, and ease of customization.

The main difference between ordinary aluminum and extruded aluminum lies in their manufacturing process and ultimate use.

Ordinary aluminum usually refers to pure aluminum or aluminum alloys that have not been further processed. It can exist in the form of casting or rolling, with basic metal properties such as good conductivity and thermal conductivity, as well as certain strength and plasticity.

Extruded aluminum refers to aluminum material processed through extrusion technology. Extrusion is a forming process in which aluminum billets are heated to a plastic state and then forced to deform through molds to form aluminum materials with specific shapes and sizes.

Yes, 8020 aluminum can be cut.

When cutting 8020 aluminum, it’s important to use the right tools and techniques to ensure clean, precise cuts. It’s also advisable to wear protective gear, such as safety glasses and gloves, to prevent injuries. Additionally, it’s crucial to follow the manufacturer’s recommendations and guidelines for cutting and modifying 8020 aluminum to ensure the best results and maintain the integrity of the material.

The main difference between the 10 series and 15 series of 8020 aluminum extrusions is their dimensions and strength capabilities.

The 10 series of 8020 aluminum extrusions typically refers to the standard extrusions that are 80mm wide and 20mm tall. These extrusions are designed for light-duty applications and can be easily cut, drilled, and machined to create custom frames and structures.

The 15 series of 8020 aluminum extrusions, on the other hand, are thicker and stronger than the 10 series. They are typically 80mm wide and 30mm tall, providing additional strength and rigidity for heavier-duty applications. These extrusions are often used in industrial and commercial applications that require a more robust framing solution, such as in equipment that needs to support heavier loads or withstand more rigorous environments.