Deep hole drilling is a specialized machining technique used to create holes with a high depth-to-diameter ratio. This process involves drilling holes that are typically several times longer than their diameter, often exceeding a ratio of 10:1. Deep hole drilling techniques find application in various industries, including aerospace, automotive, medical, and oil and gas, where precise and precision machining is required.

What is Drill in Machining?

In machining, a drill is a cutting tool used to create cylindrical holes in a workpiece. It typically consists of a rotating cutting edge, called the drill bit, which is attached to a drill machine or a drill press. Drills come in various types and sizes, each designed for specific applications and materials.

The basic design of a drill consists of a shank, which is inserted into the drill chuck or collet of the drilling machine, and a cutting portion called the drill bit. The drill bit has one or more cutting edges that remove material as it rotates and advances into the workpiece. The size and shape of the drill bit determine the diameter and geometry of the hole being drilled.

Classification of deep holes based on L/D ratio:

(1) L/D=10-20, belonging to general deep holes. Long Fried Dough Twists drills are often used on drilling machines or lathes.

(2) L/D=20-30, belonging to medium depth holes. Often machined on a lathe.

(3) L/D=30-100, belonging to special deep holes. Deep hole drills must be used for processing on deep hole drilling machines or specialized equipment.

What Are the Different Types of Drilling Machining?

Drilling machining encompasses various techniques used to create holes in a workpiece. Some of the different types of drilling machining techniques include:

1.Twist Drilling

Twist drilling is the most common drilling technique and involves using a twist drill bit with helical flutes to remove material from the workpiece. This technique is suitable for drilling holes in a wide range of materials, including metals, plastics, and wood.

2.Gun Drilling

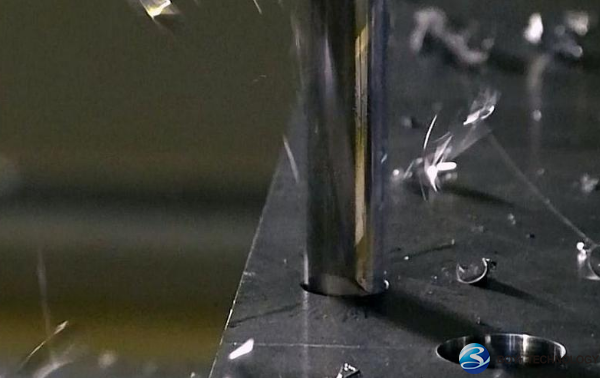

Gun drilling is a specialized drilling technique used to create deep, straight holes with high precision. It involves using a long, thin drill bit with coolant fed through the center of the drill to lubricate and cool the cutting edges. Gun drilling is commonly used in the automotive, aerospace, and medical industries for applications requiring deep holes with tight tolerances.

3.Counterboring

Counterboring is a drilling technique used to create a flat-bottomed hole with a larger diameter at the entrance. This technique is often used to create recesses for bolt heads or nuts, allowing them to sit flush with the surface of the workpiece.

4.Countersinking

Countersinking is similar to counterboring but involves creating a conical recess at the entrance of the hole instead of a flat-bottomed one. This technique is used to allow the head of a screw or bolt to sit flush with the surface of the workpiece.

5.Trepanning

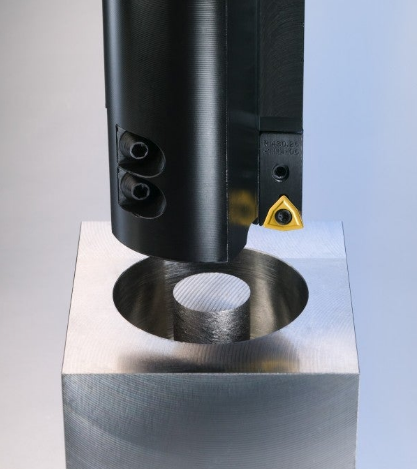

Trepanning is a drilling technique used to create large-diameter holes or remove material from the center of a workpiece. It involves using a special trepanning tool with a hollow cutting edge to cut out a circular section of material, leaving a hole in the center.

6.Peck Drilling

Peck drilling is a drilling technique used to drill deep holes in materials that are prone to chip buildup, such as cast iron or stainless steel. It involves drilling the hole in multiple shallow passes, retracting the drill bit periodically to clear away chips and prevent binding.

7.Reaming

Reaming is a machining technique used to improve the surface finish and accuracy of a pre-drilled hole. It involves using a reamer—a cutting tool with multiple cutting edges—to remove a small amount of material from the hole, resulting in a smoother, more precise bore.

These are just a few examples of the different types of drilling machining techniques used in various industries.

What Are the Uses of a Drilling Machining?

Some common uses of drilling machining include:

1.Hole Creation

The primary purpose of drilling machining is to create holes in workpieces. These holes may serve different functions, such as accommodating fasteners (e.g., bolts, screws), providing access for fluids or gases, or forming part of a larger assembly.

2.Fastening

Drilling machining is often used to create holes for fasteners such as bolts, screws, rivets, and pins. These fasteners are essential for joining multiple components together securely in various applications, including construction, automotive, aerospace, and manufacturing.

3.Threading

In addition to creating holes, drilling machines can be used to tap or thread holes, allowing them to accept threaded fasteners. This process is commonly used in manufacturing to create threads for screws, bolts, and other threaded components.

4.Boring

Drilling machines can be equipped with boring tools to enlarge or finish existing holes with high precision. Boring is often used to achieve tight tolerances, improve surface finish, or create internal features such as grooves or keyways.

5.Reaming

Reaming is a precision machining operation used to improve the accuracy and surface finish of pre-drilled holes. Reaming tools remove a small amount of material from the hole, resulting in a smoother bore with tighter tolerances.

6.Enhanced Chip Evacuation

Deep hole drilling often generates chips that can impede the drilling process. Fly cutters excel in chip evacuation, preventing chip buildup and ensuring uninterrupted drilling operations.

7.Trepanning

Trepanning is a drilling technique used to remove a circular section of material from the center of a workpiece, leaving a hole or core behind. This process is commonly used in industries such as aerospace, automotive, and oil and gas for applications requiring large-diameter holes or precise machining of cylindrical components.

8.Cooling and Fluid Passage

Drilling machines are used to create holes for cooling channels, fluid passages, and other internal features in components such as engine blocks, molds, and dies. These features help regulate temperature, improve efficiency, and optimize performance in various applications.

Faults in Drill Machining, Their Causes, and Solutions

Let’s delve into each of the faults, their causes, and the corresponding solutions in drilling machining in more detail:

1.Drill Bit Breakage:

- Cause: Excessive cutting force is the primary reason for drill bit breakage. This can result from incorrect cutting parameters such as cutting speed and feed rate. Additionally, poor quality or defective drill bits can also lead to breakage.

- Solution: Operators should carefully adjust cutting parameters within recommended limits for the specific material and drill bit size to reduce cutting force. It’s crucial to choose high-quality drill bits made from appropriate materials for the application. Regular maintenance and inspection of the drill press or machining center can help identify and address potential issues contributing to breakage, such as misalignment or worn-out components.

2.Workpiece Surface Roughness:

- Cause: Surface roughness issues can arise from incorrect cutting parameters, leading to inadequate chip removal and poor surface finish. Worn-out or dull drill bits, as well as poor workpiece clamping causing vibration and movement during drilling, can also contribute to rough surfaces.

- Solution: Operators should carefully adjust cutting parameters to optimize surface finish, ensuring they are appropriate for the material and desired finish quality. Regular replacement of worn-out or dull drill bits with sharp ones can significantly improve surface finish. Proper clamping of the workpiece is essential to minimize vibration and movement, thus enhancing surface quality.

3.Drilled Hole Deviation:

- Cause: Hole deviation may occur due to improper alignment of the drill bit, misalignment of the workpiece, or instability of the drilling machine. Poor alignment and instability can lead to off-center drilling and deviation from the intended hole location.

- Solution: Operators should use alignment tools or jigs to ensure proper alignment of the drill bit with the workpiece. Proper alignment of the workpiece on the drilling machine table is crucial to prevent misalignment and deviation. Regular maintenance and inspection of the drilling machine can help identify and address stability issues contributing to hole deviation.

4.Chip Clogging:

- Cause: Inadequate chip evacuation, improper cutting fluid application, or using a dull drill bit can lead to chip clogging. Insufficient chip evacuation results in chip buildup in the flutes of the drill bit, causing clogging and poor cutting performance.

- Solution: Operators should employ proper drilling techniques, such as peck drilling, to enhance chip evacuation and prevent clogging. Adequate application of cutting fluid is essential to lubricate and cool the cutting zone, reducing friction and chip adhesion. Regular replacement of dull drill bits with sharp ones can help prevent chip clogging and maintain cutting performance.

5.Workpiece Surface Damage:

- Cause: Surface damage can result from excessive heat generation, improper tool geometry, or insufficient cutting fluid application. Excessive heat can cause surface burning or deformation, while improper tool geometry may lead to tool marks or scratches.

- Solution: Operators should optimize cutting parameters to minimize heat generation and ensure proper tool geometry for the application. Adequate application of cutting fluid helps dissipate heat and reduce friction, preventing surface damage. Monitoring and controlling the machining process can aid in identifying and addressing potential issues promptly, thus minimizing surface damage.

Precautions During Deep Hole Drilling Machining

Here are the key points to consider when performing deep hole drilling machining:

1.Select Suitable Tools and Cutters

Choosing appropriate drills and cutters that are suitable for the material and the deep hole drilling task is crucial. Ensure that the tools have sufficient hardness and wear resistance to maintain stable performance during long periods of deep hole machining.

2.Control Cutting Parameters

Adjust cutting parameters such as cutting speed, feed rate, and depth of cut to ensure appropriate cutting forces and heat generation during deep hole drilling. Excessive cutting speed or feed rate may lead to overheating or tool wear, while too low speeds may result in inefficient machining.

The pressure and flow rate of cutting fluid are closely related to the hole diameter and machining method, as shown in the table below:

| Hole Diameter (mm) | Cutting Fluid Flow Rate (L/min) | Cutting Fluid Pressure (MPa) |

|---|---|---|

| 6-10 | 5-10 | 0.5-1.0 |

| 10-20 | 10-15 | 1.0-1.5 |

| 20-30 | 15-20 | 1.5-2.0 |

| 30-40 | 20-25 | 2.0-2.5 |

| 40-50 | 25-30 | 2.5-3.0 |

3.Effective Chip Evacuation

Effective chip removal is essential during deep hole drilling. Proper cutting fluid and cutting techniques, such as peck drilling, can help clear chips and prevent them from clogging the hole or affecting surface quality adversely.

4.Stable Workpiece Clamping

Ensure that the workpiece is securely clamped during machining to prevent vibration and displacement. Stable workpiece clamping ensures accuracy in hole positioning and machining quality.

5.Control Temperature During Machining

Deep hole drilling generates a significant amount of heat, which needs to be controlled through proper cooling and lubrication. Prompt removal of heat and chips from the cutting zone ensures stability and durability of the workpiece and tools.

Conclusion

Whether in aerospace, automotive, medical, oil and gas, or mold and die manufacturing, deep hole drilling plays a crucial role in the production of high-quality components and tooling solutions. As technology continues to advance, deep hole drilling techniques will continue to evolve, enabling manufacturers to push the boundaries of what is possible in machining.

FAQ

The main difference between machining and a drilling machine is that machining refers to a broad range of manufacturing processes used to shape or form a workpiece, while a drilling machine specifically focuses on the process of creating holes in a workpiece using a rotating drill bit. In other words, drilling is a subset of machining, and a drilling machine is a specialized tool used for drilling operations.

There are two main types of machine drills: twist drills and center drills. Twist drills have helical flutes and are versatile for drilling various materials. Center drills, also known as spot drills, have a pointed tip and are used to create starting points for other drilling operations.

A machine drill is a tool used to create holes in materials by rotating a cutting edge against the workpiece.