Welding wire is an essential component in various welding processes, serving as the consumable material that melts to form the weld. It comes in a variety of types, each suited for specific applications, with varying prices and sizes. Understanding the different types of welding wire available, their prices, sizes, and applications is crucial for achieving optimal welding results.

What Is Welding Wire?

Welding wire, also known as filler wire or consumable electrode, is a thin metallic wire used in various welding processes to join two or more pieces of metal together. It is the welding material of submerged arc welding, gas shielded welding, self-shielded welding, electroslag welding and gas vertical welding.

It serves as the material that melts and fuses with the base metal to create the weld joint. Welding wire comes in various compositions, diameters, and forms, depending on the welding process and the types of metals being joined.

Who Is the Inventor of Welding Wire?

Welding as a process has ancient origins, with early methods dating back to the Bronze Age. However, the modern understanding and techniques of welding began to emerge in the 19th century with advancements in metallurgy and manufacturing.

One significant milestone in the development of welding wire occurred with the invention of the coated electrode by French engineers Auguste de Méritens and Nikolay Benardos in the late 19th century. This coated electrode, which contained a flux coating to protect the weld from atmospheric contamination, laid the groundwork for future welding consumables, including welding wire.

One significant advancement in welding wire technology occurred with the invention of Metal Inert Gas (MIG) welding in the mid-20th century. MIG welding, also known as Gas Metal Arc Welding (GMAW), relies on a consumable wire electrode to create an arc between the electrode and the workpiece, melting both materials to form the weld joint.

What Are The Different Types Of Welding Wire?

Welding wire comes in various types, each designed for specific welding processes, materials, and applications. Here are the different types of welding wire commonly used in welding:

1.Solid Wire

Solid welding wire is made from a single material, such as mild steel, stainless steel, or aluminum. It is commonly used in Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) welding processes. Solid wire requires an external shielding gas to protect the weld pool from atmospheric contamination.

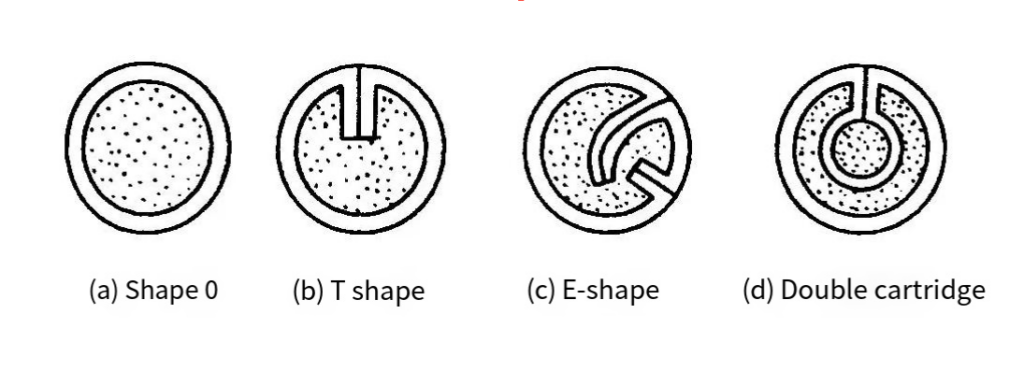

2.Flux-Cored Wire

Flux-cored welding wire looks like ordinary welding wire in appearance, but it contains flux inside, such as protecting the molten droplets and molten pool from oxidation and nitridation, assisting in forming weld seams, stabilizing the arc, deoxidizing, desulfurizing, and alloy diffusion. This eliminates the need for an external shielding gas cylinder, making flux-cored wire suitable for outdoor welding applications or situations where access to shielding gas is limited. Flux-cored wire offers better penetration and higher deposition rates compared to solid wire.

The manufacturing specifications include 1.2mm, 1.4mm, 1.6mm, 2.0mm, 2.4mm, 2.8mm, 3.2mm, and 4.0mm. Welding wires with diameters less than 2mm are generally referred to as fine diameter welding wires.

3.Metal-Cored Wire

Metal-cored wire is a hybrid between solid and flux-cored wire. It has a core consisting of powdered metals surrounded by a flux material. Metal-cored wire offers higher deposition rates and improved weld penetration compared to solid wire, making it suitable for high-speed welding applications. It provides better weld quality and reduced spatter compared to flux-cored wire.

4.Gas Tungsten Arc Welding (GTAW) Wire

Also known as TIG (Tungsten Inert Gas) welding, GTAW wire is used in the TIG welding process. Unlike other types of welding wire, GTAW wire does not typically feed through a welding gun. Instead, the welder manually feeds a filler rod into the weld pool to add material. GTAW wire is available in various compositions to match the base metal being welded, such as stainless steel, aluminum, and titanium.

The commonly used welding wires for tungsten gas shielded welding have diameters of 0.8mm, 0.2mm, 2.5mm, etc.

Table 1 lists the grades, model comparisons, and their uses of some commonly used gas shielded welding wires.

| National Standard | Grade | Compliant with the country Standard model | application | |

| GB/T8110-1995 | Recommended for gas metal arc welding (GMAW) | MG49-1 | ER49-1 | Welding low carbon steel and certain low-alloy steel structures |

| MG49-Ni M | / | For welding of 500MPa grade high-strength steel and heat-resistant steel | ||

| G50-3 | ER50-3 | Suitable for welding carbon steel and low alloy steel | ||

| MG50-4 | ER50-4 | Welding of carbon steel, thin plates, at high speed | ||

| GB/T8110-1995 | Recommended for tungsten inert gas (TIG) welding with gas shielding. | TG50Re | ER50-4 | Hydrogen arc welding for bottoming and arc welding on pipes in various positions |

| TG50 | / | / | ||

| TGR55CM | ER55-B2 | The boiler heating surface tubes, steam pipes, and high-pressure vessels | ||

| TGR55V | ER55B2MnV | Bottom welding for petroleum cracking equipment and high-temperature chemical machinery | ||

| GB/T14957-94 | HO8MnSi | / | Welding of 400MPa-grade components, mainly used for single-pass welding | |

| HO8Mn2Si HO8Mn2SiA | / | The welding of carbon steel and low-alloy steel | ||

| H11Mn2SiA | / | The welding of carbon steel and low-alloy steel | ||

5.Submerged Arc Welding (SAW) Wire

Submerged arc welding wire is specifically designed for the submerged arc welding process, where the arc is submerged beneath a layer of granular flux. This type of wire typically consists of a solid, bare metal wire without any flux coating. It is commonly used for welding thick materials in heavy-duty appli

Welding Wire Price List

The price of welding wire can vary significantly depending on various factors such as material, diameter, brand, quantity purchased, and market conditions. Here are some general price ranges based on common types of welding wire:

1.Mild Steel MIG Welding Wire:

- Prices typically range from $0.50 to $1.00 per pound for standard mild steel MIG welding wire.

- Premium quality wires or specialty wires may cost slightly more, ranging from $1.00 to $2.00 per pound.

2.Stainless Steel MIG Welding Wire:

- Stainless steel MIG welding wire is generally more expensive compared to mild steel wire.

- Prices can range from $1.50 to $3.00 per pound depending on the grade of stainless steel and other factors.

3.Aluminum MIG Welding Wire:

- Aluminum MIG welding wire tends to be among the more expensive options.

- Prices typically range from $2.00 to $4.00 per pound, with specialty alloys or high-quality wires potentially costing more.

Mastering MIG Welding Aluminum: Tips and Precautions

4.Flux-Cored Welding Wire:

- Flux-cored wires are often slightly more expensive than solid MIG wires due to the flux core material.

- Prices can range from $0.75 to $1.50 per pound for standard flux-cored wires.

Purchasing larger quantities of welding wire may lead to volume discounts, helping reduce the overall cost per pound. It’s essential to compare prices from different suppliers and consider factors such as wire quality, brand reputation, and specific project requirements when making a purchasing decision.

Welding Wire Size Chart

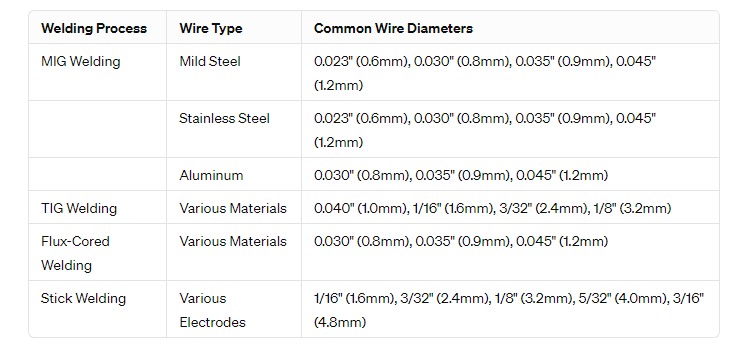

Welding wire comes in various sizes, typically measured by its diameter. The size of the welding wire is an essential consideration as it directly impacts the welding process’s performance and efficiency. Here are some common sizes of welding wire used in different welding processes:

1.MIG Welding Wire:

- Common wire diameters for MIG welding typically range from 0.023 inches (0.6mm) to 0.045 inches (1.2mm).

- Larger diameter wires, such as 0.035 inches (0.9mm) and 0.045 inches (1.2mm), are often used for thicker materials and higher deposition rates.

2.TIG Welding Rods/Wire:

- TIG welding wire diameters can vary significantly depending on the material being welded and the specific application.

- Common diameters include 0.040 inches (1.0mm), 1/16 inches (1.6mm), 3/32 inches (2.4mm), and 1/8 inches (3.2mm).

3.Flux-Cored Welding Wire:

- Flux-cored wires come in various diameters, similar to MIG wires, ranging from 0.030 inches (0.8mm) to 0.045 inches (1.2mm) or larger.

- The choice of wire diameter depends on factors such as material thickness, welding position, and desired weld characteristics.

4.Stick Welding Electrodes:

- Stick welding electrodes are typically designated by their diameter in inches or millimeters.

- Common electrode diameters include 1/16 inches (1.6mm), 3/32 inches (2.4mm), 1/8 inches (3.2mm), 5/32 inches (4.0mm), and 3/16 inches (4.8mm).

When selecting the appropriate welding wire size for your application, consider factors such as material thickness, welding position, welding process, and the specifications of your welding equipment.

What Are The Advantages And Disadvantages Of Welding Wire?

The following are the advantages and disadvantages of welding wire:

Advantages of Welding Wire:

- Efficiency: Welding wire allows for continuous feeding, which results in higher deposition rates and increased productivity compared to stick welding.

- Cleaner welds: Welding wire produces less spatter and smoke compared to other welding methods, resulting in cleaner welds that require less post-weld cleanup.

- Versatility: Different types of welding wire are available for various materials and welding processes, offering versatility in welding applications.

- Automation: Welding wire can be used with automated welding systems, improving consistency and precision in weld quality.

- Accessibility: Welding wire is widely available and easy to transport, making it convenient for use in various welding environments.

Disadvantages of Welding Wire:

- Equipment cost: Welding wire requires a welding machine and wire feeder, which can be more expensive to purchase and maintain compared to other welding equipment.

- Skill level: While welding wire offers increased efficiency, it also requires proper training and skill to set up and operate the equipment correctly.

- Potential for wire feeding issues: Welding wire may experience issues such as birdnesting, wire jamming, or erratic wire feeding if not properly maintained or if the welding parameters are not set correctly.

- Limited access in tight spaces: The welding gun and wire feeder setup may be cumbersome in tight or confined spaces, limiting accessibility for welding in certain areas.

- Flux-cored wire drawbacks: Flux-cored welding wire may produce slag that requires removal after welding, which can be time-consuming and may affect weld appearance.

Overall, welding wire offers numerous advantages in terms of efficiency, cleanliness, and versatility, but it also has its challenges and limitations that welders need to consider when selecting and using this welding method.

What Industries Use Welding Wire?

Welding wire is a crucial component in various industries where metal joining processes are required. Some of the industries that extensively use welding wire include:

- Manufacturing: Manufacturing industries utilize welding wire for various applications such as fabrication, assembly, and repair of metal components and structures. This includes industries like automotive manufacturing, machinery production, and consumer goods manufacturing.

- Aerospace and Defense: Aerospace and defense industries utilize welding wire for the fabrication and repair of aircraft, spacecraft, missiles, and military vehicles. Precision welding processes are often required in these industries to meet stringent quality and performance standards.

- Shipbuilding and Marine: Welding wire is essential in shipbuilding and marine industries for joining metal plates, pipes, and structural components to construct ships, boats, offshore platforms, and marine structures. The corrosion resistance of welding materials is crucial in marine applications.

- Energy and Power Generation: Welding wire is used in the energy and power generation sector for the construction and maintenance of power plants, including nuclear, fossil fuel, and renewable energy facilities. Welding is required for assembling boilers, turbines, piping systems, and other components.

- Automotive and Transportation: The automotive industry utilizes welding wire for the fabrication and repair of vehicle bodies, chassis, exhaust systems, and other components. Welding is also used in the manufacturing of railway vehicles, trucks, trailers, and other transportation equipment.

- Metal Fabrication: Metal fabrication shops and job shops utilize welding wire for custom fabrication projects, including the production of metal furniture, structures, artwork, and architectural elements. Welding wire enables precise and efficient metal joining in fabrication processes.

Welding is a fundamental process in metalworking, and its applications span across numerous sectors where metal joining and fabrication are essential.

Conclusion

In conclusion, welding wire plays a crucial role in various welding applications, and choosing the right type, size, and price can significantly impact weld quality, productivity, and cost-effectiveness. It’s essential to select the appropriate welding wire based on the specific requirements of each welding project.

FAQ

The type of wire used for welding depends on the specific welding process and the materials being joined. Common types of welding wire include solid wire, flux-cored wire, metal-cored wire, stainless steel wire, and aluminum wire. Each type has its own characteristics and is chosen based on factors such as the type of metal being welded, the welding technique, and the desired weld properties.

Wire welding is commonly referred to as arc welding or electric arc welding. This term encompasses various welding processes where a consumable wire electrode is used to create an electric arc that melts the base metals and forms a weld joint. Some specific types of wire welding processes include gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).