MIG (Metal Inert Gas) welding aluminum can be a challenging process due to the material’s unique properties. However, with the right techniques and precautions, it is possible to achieve high-quality welds. In this article, we’ll explore some tips and precautions to help you master MIG welding aluminum.

Understanding Aluminum

Before diving into the welding process, it’s essential to understand the characteristics of aluminum. Aluminum has a lower melting point and higher thermal conductivity compared to steel, which means it requires higher heat input and careful control of welding parameters.

Additionally, aluminum material has a low density, about one-third of that of steel, making it a lightweight material with large reserves and excellent performance; Low melting point (660 ℃); It is a face centered cubic structure with high plasticity( δ: 32-40%, ψ: 70~90%); Good specific strength and stiffness, easy to process; The formation of a dense oxide film through oxidation has good corrosion resistance and is widely used in industries such as transportation, machinery, electronics, etc.

What Is MIG Welding Aluminum?

MIG welding aluminum, also known as Gas Metal Arc Welding (GMAW), is a process used to join aluminum pieces together using a consumable wire electrode and a shielding gas. The process involves feeding the wire through a welding gun, where it melts and forms a weld pool with the base material. The shielding gas, typically a mixture of argon and helium, protects the molten weld pool from atmospheric contamination.

The inventor of MIG welding is generally credited to P.O. Nobel of the Battelle Memorial Institute in the 1940s. However, it was later commercialized by the H. Wilson Company in the 1950s. MIG welding revolutionized the welding industry by offering a faster and more efficient method of joining metal pieces together, including aluminum.

How to MIG Weld Aluminum?

MIG (Metal Inert Gas) welding aluminum requires some specific techniques and equipment due to the unique properties of aluminum. Here’s a basic guide on how to MIG weld aluminum:

- Prepare your workspace: Make sure your work area is clean, well-ventilated, and free from any flammable materials. Aluminum welding produces bright light and intense heat, so proper protection like welding curtains and personal protective equipment (PPE) such as welding helmet, gloves, and jacket are necessary.

- Select the right equipment: You’ll need a MIG welder capable of handling aluminum welding. This typically involves a MIG welder with a spool gun or push-pull gun. These guns help to feed the soft aluminum wire without it becoming tangled or jammed. Ensure your welder has appropriate settings for aluminum welding.

- Choose the right wire and gas: Use aluminum welding wire specifically designed for MIG welding. The most common type is ER4043 or ER5356. These wires are softer and have a different composition compared to steel welding wire. Also, you’ll need a shielding gas, typically pure argon or a mixture of argon and helium.

- Prepare the aluminum: Clean the aluminum thoroughly to remove any dirt, grease, or oxide layer. Aluminum forms an oxide layer very quickly when exposed to air, which can inhibit the welding process. A stainless steel wire brush or a dedicated aluminum brush can be used for cleaning.

- Set up your welding machine: Adjust your MIG welder settings according to the manufacturer’s recommendations and the thickness of the aluminum you’re welding. This includes wire speed, voltage, and gas flow rate. Start with lower settings and adjust as necessary through practice runs.

- Welding technique: Hold the welding gun at a slight angle (around 10-15 degrees) and maintain a consistent travel speed. Move the gun smoothly along the joint, ensuring good penetration without overheating the metal. Aluminum conducts heat away quickly, so watch for overheating and adjust your technique accordingly.

- Practice and test: Before welding your actual workpiece, it’s crucial to practice on scrap aluminum pieces of similar thickness. This helps you get a feel for the settings and technique required for successful aluminum MIG welding.

- Inspect and clean: After welding, inspect the weld for any defects such as cracks or incomplete fusion. Clean off any slag or spatter using a wire brush.

- Post-weld treatment: Some welds may require post-weld treatment such as brushing or grinding to achieve a smooth finish.

Always prioritize safety when working with any welding process.

Selection of MIG Welding Aluminum Materials

When selecting materials for MIG welding aluminum, it’s essential to consider the type of aluminum alloy you’ll be welding, as well as the welding wire, shielding gas, and any additional materials needed for the process. Here’s a breakdown of the materials you’ll need:

Table 1 Chemical Composition of Common Aluminum MIG Welding and Sheet Materials

| Aluminum Grade | Chemical Composition Limits wt% | ||||||||

| Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | AI | |

| 4047 | 11-13 | 0.8 | 0.03 | 0.15 | 0.1 | 0.2 | / | / | allowance |

| 4043 | 4.5-5 | 0.04 | 0.04 | 0.05 | 0.1 | 0.1 | / | / | allowance |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1 | 4.0-4.9 | 0.25 | 0.05-0.25 | 0.15 | allowance |

| 5183 | 0.25 | 0.1 | 0.1 | 0.3-1 | 4.3-5.2 | 0.25 | 0.05-0.25 | 0.11 | allowance |

| 5356 | 0.03 | 0.4 | 0.05 | 0.15 | 5 | 0.05 | 0.1 | 0.1 | allowance |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | allowance |

The selection of materials for MIG welding aluminum often needs to consider the following principles:

- Crack resistance;

- Strength;

- Corrosion resistance;

- Dilution rate;

- Color.

The 5XXX series (5000 series) is Al-Mg based, with good corrosion resistance, while the 6XXX series (6000 series) is Al-Mg-Si based, with high strength. It is recommended to use ER4047 or ER5356 for applications where strength requirements are not high, and ER4043 or ER4047 for applications with high strength requirements. ER5356 is suitable for applications requiring high strength.

When the weldability of aluminum materials encounters issues such as cracking, poor mechanical properties of weld joints, or brittle fracture, changing the welding wire without altering the design and process conditions is often a necessary, feasible, and effective technical measure. For situations requiring specific performance requirements, selecting appropriately matched welding wires is necessary. Specific details can be referenced in Table 2.

Welding Wire: Its Type, Price, Size, and Usage

Table 2 Recommended Aluminum Alloy Welding Wires for Special Performance Requirements

| Materials | In accordance with special performance requirements, recommend | ||||

| High strength | Good plasticity | Color matching after anodizing treatment | Minimal tendency to crack | Resistance to corrosion in seawater | |

| 1100 (L5-1) | SAISİ-1 | SAI-1 | SAI-1 | SAISi-1 | SAI-1 |

| 2A16(LY16) | SAICu | SAICu | SAICu | SAICu | SAICu |

| 3A21(LF21) | SAIMn | SAl-1 | SAl-1 | SAISi-1 | SAl-1 |

| 5A02(LF2) | SAIMg-5 | SAlMg-5 | SAlMg-5 | SAlMg-5 | SAlMg-5 |

| 5A05(LF5) | LF14 | LF14 | SAlMg-5 | LF14 | SAlMg-5 |

| 5083(LF4) | ER5183 | ER5356 | ER5356 | ER5183 | ER5356 |

| 5086 | ER5356 | ER5356 | ER5356 | ER5356 | ER5356 |

| 6A02(LD2) | SAIMg-5 | SAlMg-5 | SAlMg-5 | SAISi-1 | SAISi-1 |

| 6A63(LD31) | ER5356 | ER5356 | ER5356 | SAISi-1 | SAISi-1 |

| 7005 | ER5356 | ER5356 | ER5356 | X5180 | ER5356 |

| 7039 | ER5356 | ER5356 | ER5356 | X5180 | ER5356 |

Defects in Aluminum MIG Welding Joints and Their Remedies

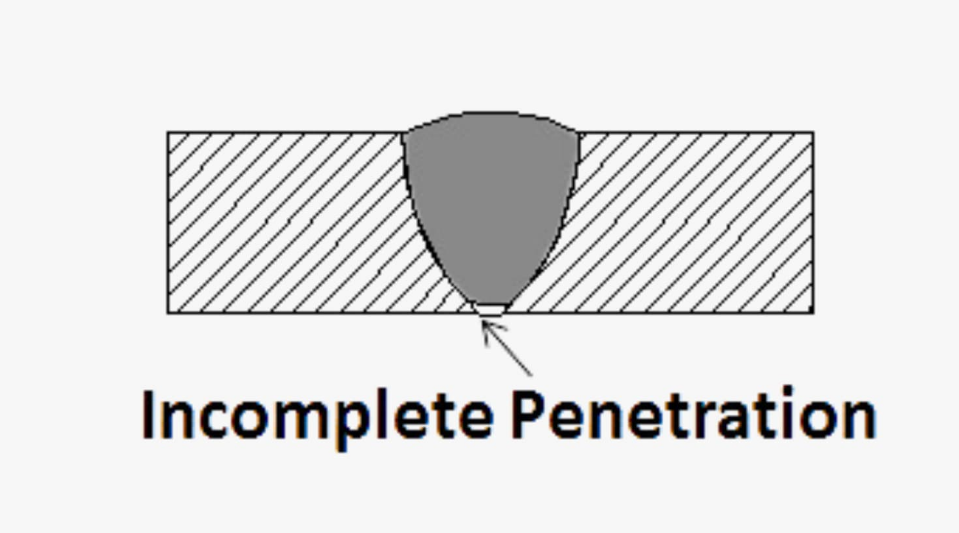

Common defects in aluminum MIG welding joints include poor weld seam formation, cracks, porosity, burn-through, incomplete penetration, lack of fusion, and slag inclusion.

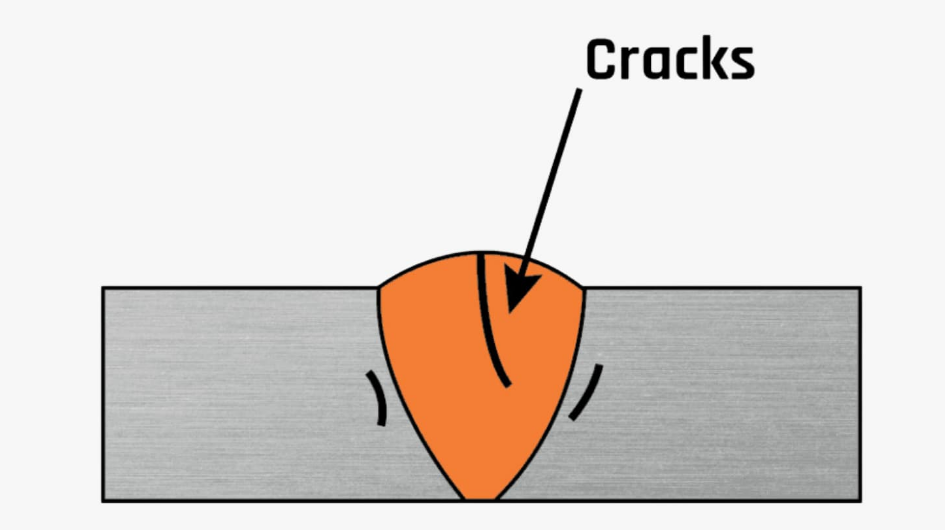

1.Cracks

Cracks are common defects in aluminum and aluminum alloy welds, typically formed during the crystallization process of the weld metal, referred to as hot cracks or solidification cracks. They may manifest as longitudinal cracks, transverse cracks (often extending into the base metal), root cracks, crater cracks, among other forms. Cracks can lead to a reduction in structural strength and even cause sudden failure of the entire structure, thus necessitating stringent prevention measures.

Causes:

a. Excessive depth-to-width ratio of the weld gap;

b. Rapid cooling of the crater at the end of the weld;

c. Incompatibility between the composition of the filler wire and the base metal;

d. Incorrect operational techniques.

Prevention measures:

a. Adjusting the arc voltage appropriately or reducing the welding current to widen the weld bead and reduce penetration depth;

b. Properly filling the crater and employing measures to slow down the cooling rate;

c. Ensuring proper matching between the filler wire and the base metal;

d. Selecting suitable welding parameters and sequence, increasing welding speed appropriately, and implementing preheating measures for areas requiring preheating.

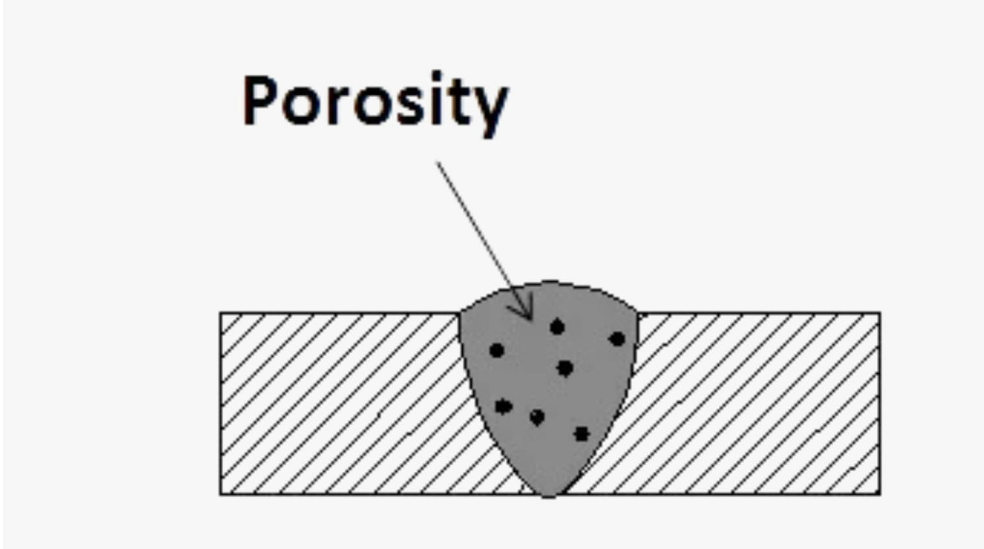

2.Porosity

Porosity refers to the presence of small voids or gas pockets within the weld metal. It weakens the weld and can lead to failure under stress. Although completely eliminating porosity is difficult, its content can be minimized through a series of measures. Depending on the different forms of porosity, various types may appear in aluminum welds, including surface porosity, dispersed porosity, localized dense porosity, single large pores, root chain porosity, and columnar porosity.

The presence of porosity reduces the density of the weld, decreases the load-bearing area of the joint, and lowers the strength and ductility of the joint. The reduction is particularly noticeable in cold bending angles and impact toughness, so measures must be taken to prevent its occurrence.

Causes:

a. Poor gas shielding, impure shielding gas;

b. Contamination of the welding wire and surface of the workpiece;

c. Excessive absolute humidity in the atmosphere;

d. Unstable arc, excessively long arc length;

e. Excessive extension length of the welding wire, excessive distance between the nozzle and the workpiece;

f. Improper selection of welding wire diameter and groove form; g. Repeated arc starting at the same location, excessive welding of joints.

Prevention measures:

a. Ensure good quality of shielding gas, appropriately increase shielding gas flow to purge the air from the welding area, and ensure uniform flow of shielding gas;

b. Thoroughly clean the welding wire and surface of the workpiece before welding to remove oil, dirt, rust, scale, and oxide film, and choose welding wire with higher deoxidizer content;

c. Choose welding locations reasonably, avoiding environments with excessively high atmospheric humidity;

d. Properly shorten the arc length;

e. Control the distance between the nozzle and the workpiece;

f. Choose thicker welding wire as much as possible and increase the thickness of the blunt edge of the workpiece groove to reduce the proportion of welding wire, thereby reducing the porosity rate;

g. Avoid repeated arc starting at the same location. If repeated arc starting is necessary, the welding area should be ground or cleaned, and the number of joints should be minimized to ensure a certain overlap of the weld seam at the joint.

Put your parts into production today

3.Weld Spatter

Weld spatter is the expulsion of molten metal droplets during the welding process. These droplets can land on surrounding surfaces, causing surface contamination. Removing spatter often requires additional cleaning efforts, which can be time-consuming and labor-intensive. Spatter not only affects the appearance of the weld but can also interfere with subsequent operations or coatings applied to the welded surface.

Causes:

a.Poor welding parameter settings, such as excessive voltage or overly fast wire feed speed, can lead to excessive spatter during the welding process.

b.Use of low-quality welding wire with unclean surfaces or improper diameters can result in increased spatter formation.

c.Incorrect welding gun angles or excessively fast welding speeds can cause instability in the weld pool, leading to spatter.

d.Surface contaminants such as oil, dirt, or rust on the welding base material can also contribute to increased spatter generation.

Preventive measures:

a.Optimize welding parameters to ensure appropriate voltage and wire feed speed settings, minimizing spatter formation.

b.Use high-quality welding wire with clean surfaces and suitable diameters to reduce spatter occurrence.

c.Maintain proper welding gun angles and control welding speed to keep the weld pool stable and minimize spatter.

d.Apply anti-spatter agents or coatings on the welding base material surface to prevent spatter adhesion, facilitate cleaning, and reduce surface contamination.

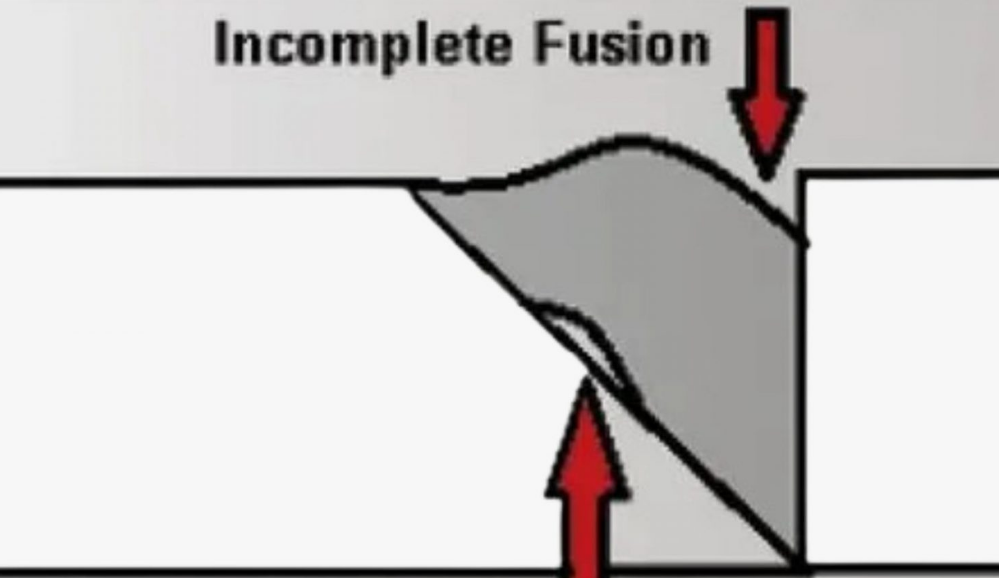

4.Incomplete Fusion or Penetration

Incomplete fusion or penetration in welding occurs when the weld metal fails to fully fuse with the base metal or when the weld does not penetrate to the desired depth. This can lead to weak weld joints with insufficient strength and integrity, compromising the overall structural integrity of the welded component.

Causes:

a.Incorrect welding parameters: Inadequate heat input due to incorrect settings of welding parameters such as voltage, wire feed speed, and travel speed can result in incomplete fusion or penetration.

b.Improper welding technique: Incorrect welding techniques, such as incorrect arc length, angle, or manipulation of the welding torch, can hinder proper fusion and penetration of the weld metal into the base metal.

c.Poor joint fit-up: Misalignment or excessive gap between the base metals being welded can prevent proper fusion and penetration of the weld metal.

d.Insufficient pre-cleaning or preparation: Contaminants such as oil, grease, rust, or mill scale on the surface of the base metal can hinder proper fusion and penetration of the weld metal.

Preventive measures:

a.Ensure correct welding parameters: Properly set welding parameters, including voltage, wire feed speed, and travel speed, are essential to achieve adequate heat input for proper fusion and penetration.

b.Use proper welding technique: Employ correct welding techniques, including maintaining the appropriate arc length, angle, and torch manipulation, to ensure proper fusion and penetration of the weld metal.

c.Ensure good joint fit-up: Properly align and fit the base metals to be welded to minimize gaps and ensure sufficient contact between the mating surfaces for proper fusion and penetration.

d.Pre-clean and prepare the base metal: Thoroughly clean and prepare the base metal surfaces by removing any contaminants, such as oil, grease, rust, or mill scale, to facilitate proper fusion and penetration of the weld metal.

Tips for MIG Welding Aluminum

By following these tips, you can improve your skills and achieve high-quality aluminum welds with MIG welding.

1.Cleanliness is Key

Before welding, ensure that the aluminum surfaces are clean and free from any contaminants such as oil, grease, or oxide layers. Use a stainless steel brush or a dedicated aluminum cleaning solution to remove any impurities.

2.Use the Right Wire and Gas

Choose a wire specifically designed for MIG welding aluminum, such as ER4043 or ER5356. These wires have additives that help to improve arc stability and reduce the formation of porosity. Additionally, use a shielding gas with high argon content (typically 100% argon or a mix with helium) to provide adequate protection and minimize oxidation.

3.Proper Wire Feeding

Aluminum wire is softer and more prone to bird-nesting or tangling compared to steel wire. Use a spool gun or a push-pull gun with a smooth, consistent wire feeding mechanism to prevent feeding issues and ensure a stable arc.

4.Adjust the Welding Parameters

Aluminum requires higher welding currents and voltages compared to steel due to its lower conductivity and higher thermal expansion coefficient. Experiment with different settings for wire feed speed, voltage, and travel speed to find the optimal parameters for your specific application.

Preheating the aluminum to around 150-200°C (300-400°F) can help reduce thermal distortion and improve weldability, especially for thicker materials.

5.Employ Proper Technique

Maintain a slight push angle (approximately 10-15 degrees) and a short arc length while welding aluminum. This helps to minimize heat input and reduce the risk of burn-through or distortion. Additionally, use a weaving motion or stitch welding technique to distribute heat evenly and prevent overheating.

Information:https://www.mig-welding.co.uk/forum/threads/straight-line-on-the-root-aluminum-mig-tig-welding.135642/

Precautions for MIG Welding Aluminum

By following these precautions, you can improve your skills and achieve high-quality aluminum welds with MIG welding.

1.Avoid Contamination

Aluminum is highly reactive with oxygen, so it is essential to protect the weld pool from exposure to air. Weld in a clean, well-ventilated area free from drafts, and use a gas lens or trailing shield to provide additional gas coverage and prevent contamination.

2.Preheat and Post-heat as Needed

In some cases, preheating the aluminum workpiece can help to reduce thermal stress and prevent cracking. Similarly, post-heating may be necessary to slow down the cooling rate and minimize distortion. Follow the recommendations provided by the welding procedure specification (WPS) or consult with a welding engineer for guidance.

3.Use Proper PPE

Always wear appropriate personal protective equipment (PPE), including a welding helmet with a shade suitable for aluminum welding, heat-resistant gloves, and protective clothing. Additionally, ensure adequate ventilation to prevent exposure to welding fumes and gases.

Conclusion

Mastering MIG welding aluminum requires a combination of proper technique, equipment, and precautions. By following the tips and precautions outlined in this article, welders can achieve high-quality aluminum welds with minimal defects and distortion.

Boyi provides reliable MIG welding services. With our powerful facilities and strict quality inspection processes, we ensure the production of high-quality welded parts. Contact us now to start your project!

Put your parts into production today

FAQ

Yes, you can weld aluminum with a MIG (Metal Inert Gas) welder, but it requires a few considerations and specific equipment. Welding aluminum with a MIG welder typically involves using a spool gun rather than a traditional MIG gun. This is because aluminum wire is softer and more prone to tangling than steel wire, and feeding it through a conventional MIG gun can be difficult.

MIG welding wire used for aluminum has specific alloy compositions, typically including aluminum alloys such as 4043, 5356, and 5554. These wires are relatively soft to prevent tangling during welding. The choice of wire diameter depends on the thickness of the aluminum and welding parameters. Aluminum MIG welding wire must be able to feed smoothly through MIG welding systems, including spool guns, to ensure continuity and stability during welding.

Yes, you need shielding gas to MIG weld aluminum. Shielding gas is essential for protecting the weld pool from atmospheric contamination during the welding process. When welding aluminum with a MIG welder, a mixture of inert gases, typically argon and helium, is used as shielding gas.