Cutting tools for CNC lathes, as a critical component, come in a variety of types with diverse functions. They achieve precise machining of workpieces by accurately controlling cutting forces, cutting speeds, and cutting depths. Moreover, continuous innovations in materials, structures, and coating technologies of cutting tools provide strong support for the machining capabilities of CNC lathes.

This article systematically categorizes CNC lathe cutting tools, providing detailed descriptions of their respective functions and characteristics. It also explores application strategies in practical production.

What is a Lathe Tools?

A lathe tool, often simply referred to as a tool bit or cutting tool, is a specialized cutting implement used in lathe machines operations. Lathes are machine tools that rotate a workpiece on its axis while various cutting tools are applied to shape, cut, drill, or otherwise manipulate the material. Lathe tools come in a variety of shapes, sizes, and materials, each suited for specific machining tasks.

lathe cutting tools usually consist of a tool body and a blade. The blade body is the main body of a cutting tool, usually made of steel or hard alloy, used to fix the blade and transfer cutting force to the workpiece. The blade is the cutting part, usually made of high-speed steel, hard alloy or ceramic, and its shape and blade geometry are determined by the machining requirements and workpiece material.

Put your parts into production today

Types of Lathe Cutting Tools

Based on their purposes, lathe cutting tools can be broadly categorized into two types: those based on the method of tool usage and those based on the method of application feed.

Classification 1: Lathe Tools Based on Usage Methods

According to the usage of lathe cutting tools, the following are 10 common lathe cutting tools:

1.Thread tools

Thread lathe tools for lathes are specialized tools used for machining threads, and they can be classified into two types based on their purpose and machining method:

- External thread lathe tools: Also known as thread cutting tools, these are specifically designed for machining external threads on workpieces. These tools are engineered with specific thread profiles and dimensions to cut the required external threads on the lathe. External thread cutting tools typically feature one or more cutting edges to ensure precision and efficiency in thread machining.

- Internal thread lathe tools: Internal thread lathe tools are used for machining internal threads within the holes of workpieces. These tools often come in various shapes and sizes of cutting edges to form the desired internal threads inside the workpiece. Internal thread lathe tools include types such as thread taps and thread mills, which can be selected based on the material of the workpiece and thread requirements.

2.Chamfering tools

Chamfering lathe tools are used to create beveled edges or grooves on workpieces. They are employed to chamfer the corners of workpieces to enhance appearance, reduce sharp edges, and improve safety. Specific chamfering lathe tools with flank angles are required when extensive chamfering work is needed.

1.Application:

- Chamfering lathe tools are primarily utilized to chamfer the edges of workpieces, reducing sharp edges and enhancing appearance.

- They are commonly used in the manufacture of bolts, nuts, part edges, mechanical components, etc., to ensure the workpieces have the appropriate appearance and quality.

2.Features:

- Chamfering lathe tools typically feature specific tip designs to ensure chamfering accuracy and consistency.

- Depending on the machining requirements, chamfering lathe tools may have different cutting angles and tool shapes, such as 45-degree, 60-degree, or 90-degree chamfering tools.

3.Turning tools

Turning tools are tools used to perform turning operations on workpieces on lathes. Depending on their purpose and processing method, they can usually be divided into two main types:

1.Roughing turning tool:

- Roughing turning tools are primarily used to remove a large amount of metal in the shortest time possible.

- These tools typically have larger cutting angles and tool tip radii to withstand greater cutting forces and expedite rapid metal removal.

- Roughing turning tools have larger cutting angles and faster cutting speeds, suitable for preliminary rough machining of workpieces to prepare for subsequent finishing operations.

2.Finishing turning tool:

- Finishing turning tools are mainly used to remove small amounts of metal and produce extremely smooth and precise surfaces.

- These tools are meticulously polished, with finer cutting angles, providing higher surface quality and machining accuracy.

- Finishing turning tools have relatively smaller cutting angles and slower cutting speeds, suitable for fine machining of workpieces to improve surface quality and dimensional accuracy.

In CNC machining, roughing and finishing turning tools are often used in conjunction. Roughing turning tools are first used for rapid material removal, followed by finishing turning tools for precise dimensioning and surface finishing. This coordinated use ensures both machining efficiency and high-quality machining results.

4.Slotting tools

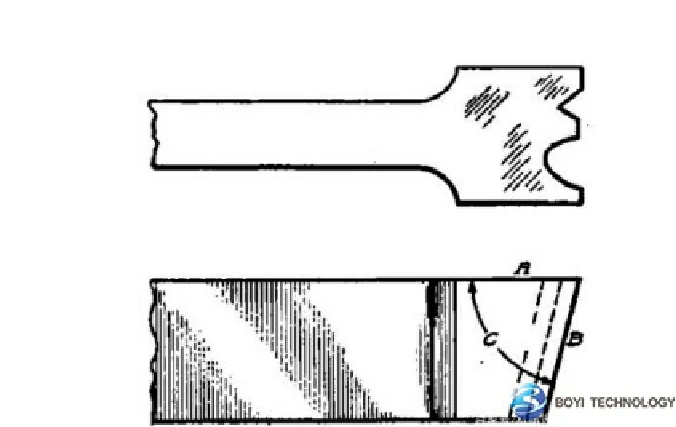

Slotting lathe tools are utilized to create narrow grooves or recesses of a certain depth on the cone, cylinder, or surface of a workpiece. During the machining process, they cut channels of a certain depth to provide necessary space or groove shapes to meet specific workpiece design or assembly requirements. They are commonly employed in manufacturing keyways, grooves, apertures, channels, or other specialized shapes of parts to fulfill mechanical assembly or other process requirements.

Depending on the shape of the required groove, slotting lathe tools with corresponding tool tip shapes can be selected. These tools may have square, circular, V-shaped, or other tip shapes to accommodate various groove machining needs.

5.Facing tools

Facing tools are used for machining on the end face of a workpiece. Facing tools are somewhat similar to milling tools in that they are both used for cutting operations on the surface of a workpiece. However, the design and operation of facing tools may vary depending on the specific machining equipment, but typically involve a cutting tool that can move horizontally along the end face of the workpiece to remove material and form the desired surface. Facing operations can be used to prepare the end face of a workpiece for further machining operations or to meet specific requirements for dimensions, flatness, and surface roughness.

You can learn more about milling information:https://www.boyiprototyping.com/cnc-machining-guide/up-milling-and-down-milling-difference/

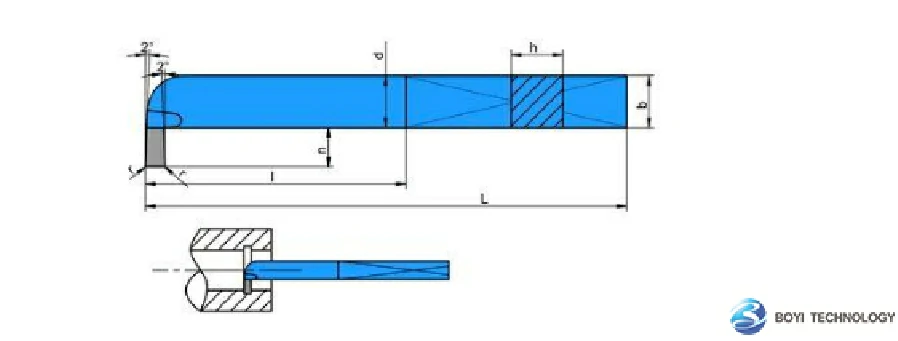

6.Boring tools

A boring tool is a type of machine tool used to enlarge holes. It typically consists of a tool body, a tool shank, and a cutting head. The tool body is the main component used to hold the tool shank and cutting head, while the tool shank is the part that connects the tool to the machine tool’s spindle. The cutting head is the actual part used to cut the workpiece and enlarge the hole diameter. When you want to enlarge an existing hole, you need to use a boring bar. The boring bar can easily drill into the pre-drilled hole and enlarge its diameter.

Here are some common types of boring tools:

- Manual boring tool: This type of boring tool requires the operator to manually rotate the boring bar to cut the workpiece and enlarge the hole diameter.

- Automatic boring tool: Automatic boring tools have automatic feed functions, allowing them to automatically process the workpiece after setting the cutting parameters, thus improving processing efficiency.

- CNC boring tool: This type of boring tool can be used with CNC machine tools, where the cutting process is controlled by CNC programs, enabling precise machining.

7.Molding tools

Molding tools are used to manufacture components of various shapes, and they are characterized by their ability to cut or shape according to the desired form. These tools are typically employed in the machining of materials such as metal, plastic, wood, etc., for the production of various parts, products, or components.

The design of molding tools can vary based on the desired shape of the workpiece, which may include internal contours, external contours, holes, slots, etc. During the manufacturing process, molding tools are usually fixed onto machining equipment using special covers or supports. Subsequently, cutting or shaping operations are performed at appropriate speeds and pressures.

8.Counterbore tools

Counterbore tools are tools used for machining holes in workpieces, typically employed to enlarge the aperture and create a flat bottom in the hole to accommodate the head of a screw or other component. They are commonly used in the following two scenarios:

- Creating counterbores in pre-drilled holes on the workpiece: In this case, there is already a hole present on the workpiece, but it needs to be enlarged to accommodate a larger diameter screw or bolt. Counterbore tools remove material from the inner surface of the hole, increasing its diameter.

- Counterboring on the workpiece: In this scenario, there may not be any holes on the workpiece, or there is a need to add a hole in a new location. Counterbore tools cut a new hole on the surface of the workpiece.

Counterbore tools typically have two radii, one for cutting the inner surface and another for cutting the outer surface. This ensures that the hole on the workpiece fits the screw or bolt correctly and is accurately positioned.

9.Reaming tools

A reaming tool is used for precision machining of existing drilled holes or holes drilled beforehand. In typical scenarios, there might be slight discrepancies in the dimensions of the drilled hole or the surface roughness may not meet requirements. In such cases, a reaming tool is employed to further refine the hole, ensuring its dimensional accuracy and surface quality. Reaming tools typically feature specialized designs and cutting edges that rotate within the hole wall to remove material, achieving precision machining. Utilizing a reaming tool enhances the geometric accuracy and surface finish of the hole, while also ensuring that its dimensional tolerance falls within permissible limits.

10.Bottoming tools

Bottoming tool is a cutting tool similar to a slotting tool. It is typically used to perform bottom cutting at a certain distance from the hole end to enlarge the hole diameter. This type of cutting is commonly applied on internal threads to achieve the desired clearance or dimension. Bottoming cutters are usually designed in various shapes and sizes to accommodate different types and sizes of holes. They may feature different cutting head designs to efficiently fulfill specific machining tasks. These tools may employ single or multiple blade designs, depending on the required cutting quality and efficiency.

Put your parts into production today

Classification 2: Lathe Tools Based on Applying Speed

Lathe tools can indeed be categorized based on the direction of feed during the machining process. Here are the three primary categories based on this criterion:

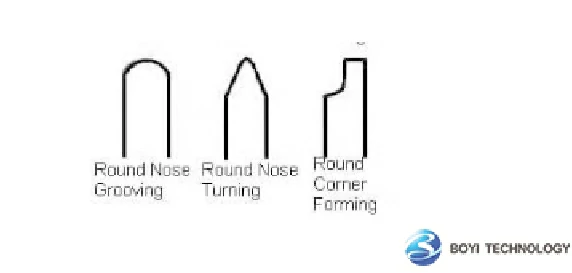

1.Round nose tools

The round nose tool, also known as the ball nose tool or spherical tool, is characterized by its cutting part shaped like an arc or a sphere. This design allows the tool to cut in multiple directions, not just in straight or arcuate paths. Without obvious side or back rake angles, the round nose tool can produce smoother surfaces during the machining process, reducing burrs and roughness. Due to its ability to cut in multiple directions, the round nose tool is particularly suitable for machining complex curved surfaces, such as spherical, convex, or concave surfaces.

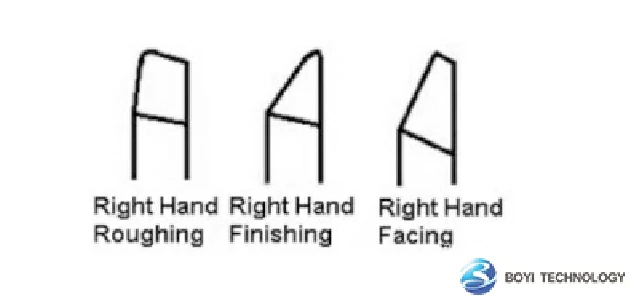

2.Right-hand tools

A right-hand cutting tool removes material when moving from right to left (requiring only a top view with the rake face facing upward). The nomenclature of “right-hand tool” is used based on an analogy with the human hand. Using the right hand as a reference, the thumb represents the direction of tool feed. Therefore, the main cutting edge of the tool is located on the left side of the tool.

In the context of lathe operations, a right-hand tool is designed for cutting operations where the tool is fed in a direction that corresponds to the natural movement of the right hand. This tool orientation ensures that the cutting forces act in a manner that promotes stability and efficiency during the machining process.

The main cutting edge of a right-hand tool is positioned such that it engages the workpiece in a way that facilitates material removal. As the tool moves from right to left, the cutting edge gradually removes a layer of material from the workpiece, creating a smooth and precise cut.

3.Left-hand tools

Unlike right-hand cutting tools, left-hand tools remove material when moving from left to right (with the rake face visible in a top view). Using the left hand as a reference, the thumb represents the direction of tool feed. Consequently, the main cutting edge of the tool is located on the right side of the tool.

In lathe operations, a left-hand tool is designed for those cutting applications where the tool needs to be fed in a direction that corresponds to the natural movement of the left hand. This orientation ensures that the cutting forces act in a way that promotes stability and efficiency during the machining process.

The positioning of the main cutting edge on a left-hand tool allows it to engage the workpiece in a manner that effectively removes material. As the tool moves from left to right, the cutting edge gradually peels away a layer of material from the workpiece, resulting in a smooth and accurate cut.

How to Use Lathe Tools?

Using lathe tools requires some skill and knowledge of the lathe machine and the various cutting tools available. Here’s a basic guide on how to use lathe tools:

1.Safety First: Before starting any work on the lathe, ensure that you’re wearing appropriate safety gear, including safety glasses and possibly ear protection.

2.Select the Right Tool: Lathe tools come in various shapes and sizes, each designed for specific tasks. Common lathe tools include gouges, scrapers, parting tools, and skew chisels. Choose the tool appropriate for the task you’re performing.

3.Tool Setup: Install the tool into the tool post or tool holder of the lathe. Make sure it’s securely tightened to prevent any accidents.

4.Tool Height: Adjust the height of the tool to the centerline of the workpiece. This ensures proper cutting action and prevents damage to the tool and workpiece.

5.Positioning: Position the tool close to the workpiece but without touching it. Use the lathe’s manual controls to move the tool into the desired position.

6.Tool Rest: If available, use a tool rest to support the tool during cutting. This provides stability and control, especially when making deeper cuts.

7.Cutting Technique: Depending on the type of lathe tool and the material you’re working with, there are various cutting techniques you can employ. Some general tips include:

- Start with light cuts and gradually increase the depth of cut as needed.

- Keep the tool rest close to the workpiece to minimize vibration.

- Use smooth, controlled movements to guide the tool across the workpiece.

- Maintain a consistent cutting speed to achieve a smooth finish.

- Pay attention to the sound of the cutting action. Adjust the speed or cutting depth if necessary.

8.Chip Clearance: Make sure there’s adequate clearance for chips and debris to avoid clogging the cutting area. Use a brush or air blast to remove chips as needed.

9.Coolant (if applicable): Depending on the material being cut and the type of lathe operation, you may need to use coolant or cutting fluid to lubricate the cutting action and dissipate heat.

10.Inspect and Adjust: Periodically stop cutting to inspect the workpiece and tool. Make any necessary adjustments to the tool position, cutting depth, or lathe speed to achieve the desired result.

11.Finish and Cleanup: Once you’ve completed the cutting operation, turn off the lathe and carefully remove the workpiece. Inspect it for any defects or imperfections and make any necessary adjustments.

12.Maintenance: After use, clean the lathe tools and return them to their storage location. Check for any signs of wear or damage and replace or repair as needed.

What Are the Applications of Lathe Tools?

The application of lathe tools is extremely versatile, as they can be used to process a variety of parts. Turning tools are primarily used for machining rotational parts, including inner and outer cylindrical surfaces, end faces, conical surfaces, profiled surfaces, and threads. Whether it’s the outer surface of a cylindrical workpiece, inner cylindrical surface, or flat workpiece, lathe tools can perform precise cutting operations.

Additionally, lathe tools can be used to machine various grooves, such as keyways, back grooves, dovetails, etc. For workpiece surfaces with special angles, such as conical surfaces, inclined planes, etc., there are specialized angle tools for machining. If it is necessary to cut off a workpiece or cut off a section from the workpiece, a cutoff tool is the ideal choice.

On a lathe, by using different types of lathe tools, parts of various shapes can be machined, such as straight shafts, discs, sleeve-type parts, etc. For parts with multiple axes, such as crankshafts, eccentric wheels, or disc camshafts, they can also be machined by changing the installation position of the workpiece or appropriately modifying the lathe.

BoYi Meets All Kinds of CNC Turning Machining Needs

BoYi offers comprehensive solutions to meet a wide range of CNC turning machining needs. With advanced technology and expertise, BoYi ensures precision and efficiency in every project. Whether it’s complex geometries, tight tolerances, or high-volume production, BoYi delivers superior CNC turning services. Our experienced team is dedicated to providing customized solutions tailored to meet the specific requirements of each client. From prototyping to mass production, BoYi is your trusted partner for all CNC turning machining needs.

Put your parts into production today

Welfare: More Tools Classified By Cutting Process

Machine tool according to the different cutting methods and processing technology can be divided into turning, milling, drilling, the three processing methods of turning and milling accounted for relatively high.

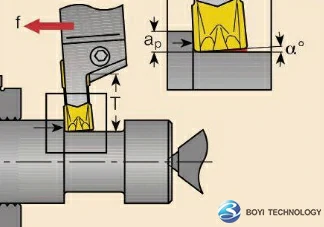

(1) Turning machining includes: outer circle, inner circle, section and other processing, shaft, ring and other parts of the grooving, copying or cutting processing, fastening joint thread processing, etc., mainly used in general machinery, automobiles, rail transit, precision bearings, high-end sanitary ware, petrochemical and other fields.

(2) Milling machining includes: profile, plane, square shoulder, copying, groove and other processing, mainly used in precision mold, energy equipment and other fields.

(3) Drilling machining includes: machining hole drilling processing, mainly used in construction machinery, new energy and other fields.

Table 1: According to the cutting method, the machine tool can be divided into: turning, milling, drilling

| Cutting method | Main machining structure | Main application field | Image example |

|---|---|---|---|

| Turning | Turning of outer circles, inner circles, and cross-sections; Cutting, profiling, or cutting of parts such as shafts and rings; Thread machining of fastening connectors | General machinery, automobile, rail transit, precision shaft water, high-end sanitary ware, petrochemical, etc |  |

| Milling | Milling machining of profiles, planes, shoulders, profiles, grooves, etc | Precision mold, energy equipment, etc |  |

| Drilling | Machining medium hole drilling | Construction machinery, new energy and so on |  |

Conclusion

By selecting the appropriate CNC lathe cutting tool and programming the CNC machine accordingly, manufacturers can achieve efficient and accurate machining of various workpieces across a wide range of industries.You can also find out more about our CNC machining guide.

FAQ

When using a wood lathe, there are several essential tools you’ll need, but the four basic ones are:

1.Lathe Chuck or Faceplate: These are used to secure the wood to the lathe spindle. A chuck grips the wood from the outside, while a faceplate attaches to the end of the wood blank.

2.Turning Tools: These are specialized cutting tools designed for shaping wood on a lathe. Common types include gouges, chisels, scrapers, and skew chisels. They come in various sizes and shapes for different cutting tasks.

3.Tool Rest: This is a support that mounts to the lathe bed and provides a stable platform for the turning tools. It’s adjustable in height and distance from the workpiece, allowing for precise control during shaping.

4.Safety Equipment: Safety goggles or a face shield are essential to protect your eyes from wood chips and debris that can fly off the spinning workpiece. Additionally, a dust mask or respirator is important to protect your lungs from wood dust generated during turning.

Using lathe tools is not difficult, but it requires some learning and practice. First, you need to understand the different types of lathe tools and their purposes, such as cutting tools, drilling tools, and so on. Then, learn how to properly secure the workpiece and adjust the lathe’s speed and feed rate to achieve the desired cutting effects. Additionally, mastering the correct cutting techniques and safe operating practices is crucial. Through step-by-step learning and practice, you can gradually become proficient in using lathe tools.