Glass 3D printing is an advanced manufacturing technology that uses a working principle similar to fused deposition molding (FDM). This technology has remarkable features, as it can print molten lines layer by layer, providing scientists and artists with a new way to explore customized glass manufacturing. Next, we will explore in detail the working principle of glass 3D printing, the components of the printer, and gain a deeper understanding of its applications in different industries.

3D printed glass: the basics

The manufacturing process of glass 3D printing is relatively complex, unlike long fibers filled with wood or metal, glass cannot be easily dispersed in the material like they are. At present, mainstream glass 3D printers still use FDM printing technology and require the use of pure glass for printing.

The entire manufacturing process involves grinding glass, melting glass, and producing the silk required for printers. Many professionals engaged in glass 3D printing typically prepare their own material inventory. Subsequently, the molten glass was printed layer by layer into a linear form using a 3D printer. Although the entire process is similar to FDM, the most significant difference is that glass 3D printers require higher heat. The printing temperature can reach 1300 ° C, while the chamber temperature can reach up to 400 ° C, which is equivalent to an extremely high temperature hot nozzle.

This high-temperature environment requires a precise temperature control system to ensure that the glass can melt and solidify at the appropriate temperature, achieving successful 3D printing. The advancement of this technology requires professional knowledge to ensure the stability and success of the entire manufacturing process.

3D printing materials

There are various types of glass, including sodium calcium glass, artistic glass, crystal glass, borosilicate glass, etc. Different types of glass have their own unique performance characteristics.

Sodium calcium glass: This type of glass usually contains high levels of sodium oxide and calcium oxide, and has good resistance to chemical erosion, making it suitable for the manufacture of laboratory instruments and glassware.

Art glass: Art glass is known for its rich colors and textures, suitable for fields such as art and decoration, providing unique visual effects.

Crystal glass: Crystal glass with high transparency and optical refractive index is commonly used to make tableware, jewelry, and decorations, giving products a noble appearance.

Borosilicate glass: containing boron and silicon elements, with a low coefficient of thermal expansion, suitable for applications in high-temperature environments, such as thermal batteries and nuclear industry.

Materials Guide

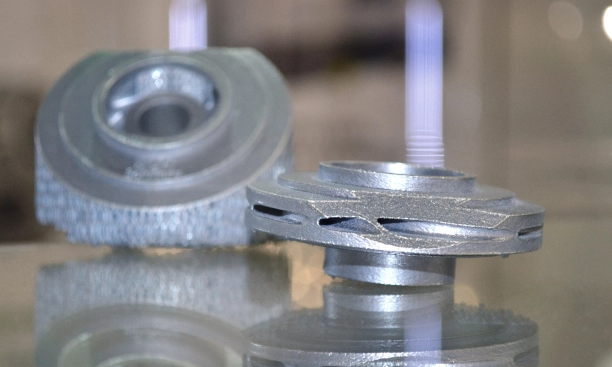

The glass 3D printer uses glass rods as raw materials. Various types of glass rods are inserted into the 3D printer through the holes on the top of the device, flowing towards the heating element, and then transported to the nozzle. After being processed by a crusher, the discarded glass enters the processing equipment and is transformed into glass rods after treatment. This device is capable of stretching molten glass into rods with a diameter between 3.5 and 6 millimeters, for use in glass 3D printers. Through this technology, flexible applications of different types of glass have been achieved, thereby expanding the wide range of applications of glass 3D printing.

Glass 3D printing process

Glass 3D printing is a complex and precise process that includes the following steps:

Raw material preparation: Different types of glass are processed into glass rods. This may involve steps such as melting, forming, and stretching the glass to ensure that the glass rod has the appropriate diameter and quality.

Feeding system: The glass rod enters the 3D printer through the hole on the top of the device. This step requires ensuring the continuous supply and stable feeding of raw materials to avoid interruptions during the printing process.

Heating element: The glass rod flows towards the heating element, usually a high-temperature furnace or melting chamber. Here, the glass rod is heated to a sufficiently high temperature to make it malleable and easy to shape.

Nozzle system: The heated glass is transported to the working area of the 3D printer through the nozzle system. The design of the nozzle system is related to the accuracy and speed of printing, usually requiring consideration of material fluidity and nozzle temperature control.

Printing process: The 3D printer stacks glass layer by layer according to the predetermined model and path. This process requires highly precise mechanical systems and advanced control technology. Glass is precisely positioned and stacked on each layer to form the final component.

Cooling and Curing: The printed glass parts need to gradually solidify during the cooling process. The control in this stage affects the internal structure and performance of the parts. The cooling process needs to be carefully controlled to avoid cracks and deformation.

Post processing: After printing, glass parts may require post-processing steps, such as removing supporting structures, surface finishing, or sintering, to meet design and quality requirements.

The entire process of 3D printing on glass requires a high-temperature environment, advanced sensors, and precise control systems to ensure that each step can be completed accurately and efficiently.

Glass 3D printing application

The application fields of glass 3D printing technology are constantly expanding, providing innovative solutions for various industries. Here are some application examples of glass 3D printing technology:

1.Architectural design and decoration

Glass 3D printing can be used to create unique architectural elements such as decorative walls, art pieces and Windows. Custom art structures, sculptures and architectural details can be achieved through glass 3D printing, giving the building a unique look and style.

2.Medical equipment and laboratory equipment

Glass 3D printing can be used to manufacture medical devices and laboratory equipment, such as micro-reactors, laboratory containers, customized medical sensors and optical inspection equipment. This provides more precise and personalized solutions for the medical and scientific fields.

3.Electronic device packaging

In electronics manufacturing, glass 3D printing can be used to create customized electronic device packages. This provides higher protection and temperature stability, suitable for electronic components in some special environments.

4.Transparent parts in the automotive sector

Glass 3D printing technology can be used to make transparent parts in cars, such as Windows and lamps. This provides more flexible design options, making the car look more unique and personal.

5.Glass fiber reinforced material

Using glass 3D printing technology, it is possible to manufacture composite materials with glass fiber reinforcement. Applications of this material in the field of communication, such as the manufacture of high-performance fiber optic connectors and optical devices.

Conclusion

In summary, glass 3D printing technology is still in its early stages but shows tremendous growth potential, especially in terms of technology adoption. With efforts from commercial equipment sales companies, we anticipate glass 3D printing becoming more efficient and user-friendly in the future, further expanding and advancing. This will provide more possibilities for innovation across various fields, and with the continuous reduction in 3D printing costs, bring new opportunities and challenges to the glass manufacturing industry.

FAQ

3D printing with glass involves innovative techniques such as using glass-infused filaments in FDM, sintering glass powder with SLS, and utilizing glass resin in SLA/DLP methods. Researchers are exploring ways to directly 3D print with molten glass, facing challenges related to its high melting point and thermal stresses. Although not as prevalent as other materials, glass 3D printing showcases promising applications, offering the potential for creating intricate and transparent structures through layer-by-layer fabrication. Ongoing research continues to address technical hurdles and push the boundaries of glass-based additive manufacturing.

Some glass based materials can be used for 3D printing, such as glass fiber reinforced polymers. These materials can be printed using the same method as plastic materials, but they still require special equipment and materials to print.