Metal 3D printing technology has important application prospects in the field of automotive manufacturing. It can not only rapidly manufacture prototypes, accelerate the new car development process, but also directly produce small batches of parts, shorten the supply chain and reduce costs, becoming a key complementary technology in the automotive industry.

In addition, the unique advantages of 3D printing in manufacturing complex parts help simplify the structure of automotive components, reduce weight, and save materials. Although technology has the potential to be faster, more economical, and manufacture more complex components, its widespread application in the field of automotive manufacturing is still limited so far. In the future, only technologies with more efficient, economical, and flexible manufacturing capabilities can truly become the mainstream way of automobile manufacturing.

3D printing in today’s automotive industry

In today’s automotive industry, 3D printing technology was not initially adopted directly by car manufacturers, but was first applied by their sponsored fleet. For decades, from Ford to Ferrari, many companies have viewed racing as an incubator for testing new technologies. Nowadays, many standard car features, such as regenerative braking systems, button ignition systems, and even rearview mirrors in hybrid vehicles, can be traced back to the innovations of these racing cars. The same applies to 3D printing technology, especially metal printing. Formula One teams, World Endurance Challenge teams, Formula E teams, and others have all experienced the benefits of additive manufacturing, including rapid design iterations, rapid prototyping, and lightweight components, all of which can improve vehicle performance on the track.

Despite having so many manufacturing advantages, why hasn’t 3D printing been widely adopted by car manufacturers? This may be because adopting new technologies involves complex adjustments and investments throughout the entire production process. However, with the continuous development and maturity of technology, it is expected that automobile manufacturers will gradually recognize the potential value of 3D printing, including faster and more flexible manufacturing processes, as well as the long-term benefits of optimized design and lightweight components. Therefore, it is expected to see a wider adoption of 3D printing technology in the automotive manufacturing industry in the future.

Currently, the types of materials compatible with 3D printing technology are relatively limited. Taking plastics as an example, most materials currently available for molding can only meet limited needs. For automotive manufacturers with higher requirements for applications, existing materials cannot even pass laboratory testing.

The raw material cost of technology is extremely high, even after experiencing significant price reductions, the price of metal powder still reaches hundreds or even thousands of yuan per kilogram, resulting in the cost of finished parts possibly reaching hundreds to thousands of yuan per kilogram. This is too costly for large-scale production.

Although 3D printing has achieved some success in the automotive industry, especially in racing where it can withstand the high cost of printing complex components to achieve victory, it can only be extended to a wider range of manufacturing processes with more cost-effective technology. Currently, most components are still produced using traditional methods such as die casting, CNC machining, and stamping.

Selective laser melting (SLM)

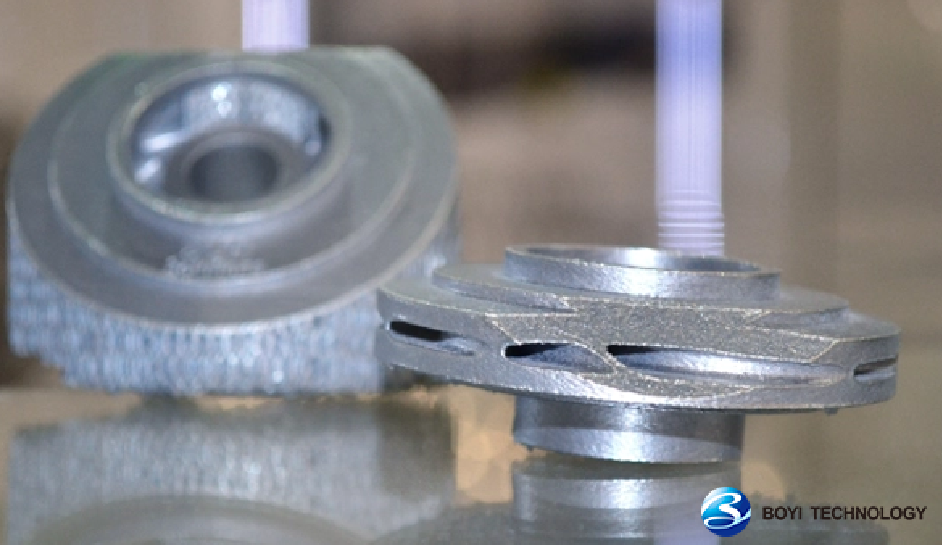

Selective laser melting technology is considered more suitable for small batch, high-value applications. This technology has been widely used in the field of automotive manufacturing by using laser to melt metal powder layer by layer, in order to quickly and accurately manufacture metal parts. Automobile manufacturing companies such as BMW, Ford, Volkswagen, and Mercedes Benz have all achieved significant success in adopting this technology, achieving mass production under certain conditions. However, most of these successful cases are limited to high-end brands, and the overall manufacturing volume is still limited.

This phenomenon can be traced back to the limitations of Selective laser melting technology in terms of cost, materials, and speed. The Selective Laser Melting equipment requires a huge upfront investment, with a complete system cost of up to $2 million or more. The scale of producing 1 ton of parts per year does not justify the cost. In addition, although 3D printing makes metal parts manufacturing more flexible, printing is only the first step in the entire manufacturing process, and subsequent post-processing processes such as support removal further increase the cost of the parts.

Although Selective laser melting technology has shown significant manufacturing advantages in the automotive field, such as integration, high precision, and complex manufacturing, a series of high-value applications have all originated from this technology. However, these applications are generally limited and mainly limited to high-end brands, making it difficult to meet the demand of the automotive manufacturing industry for low-cost, large-scale manufacturing.

Desktop metal 3d printing based on extrusion

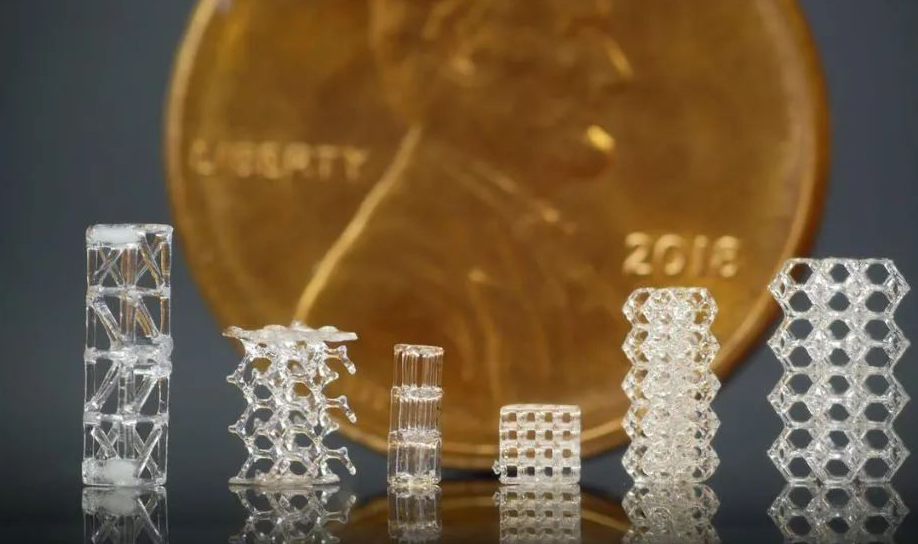

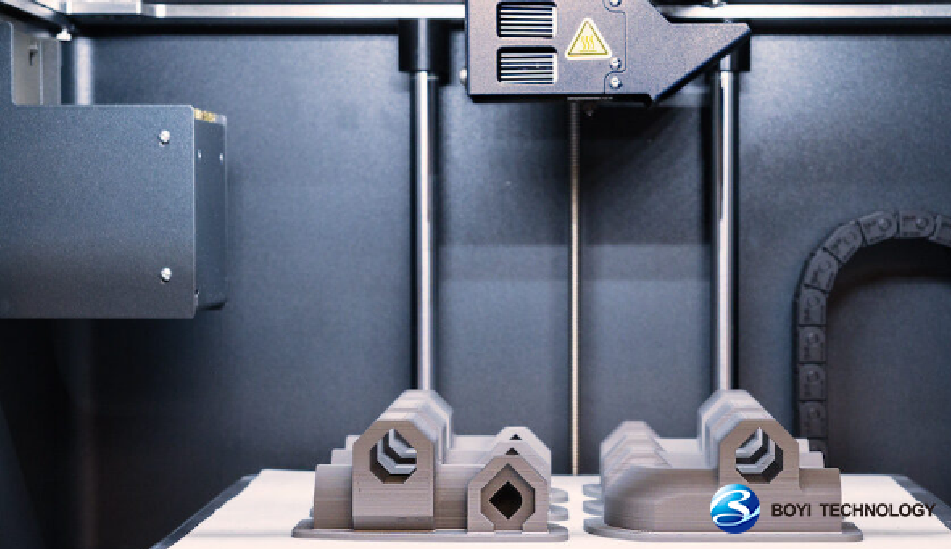

Desktop metal 3D printing technology is based on extruded desktop metal 3D printers, with a convenient design for office use, avoiding potential risks of dust and laser exposure, and providing a more user-friendly end-to-end solution.

For users in the early stages of new car design and manufacturing, desktop metal 3D printers are more cost-effective and convenient to operate compared to traditional powder bed equipment. This type of system can quickly produce a large number of prototype parts internally, quickly verify different design concepts, explore new structural possibilities, and thus save time and cost in the long and expensive design cycle. This not only reduces development costs, but also enables companies to transition more quickly from the design and validation phase to production, accelerating product launch. Flexible operability also helps to reduce costs, reduce material waste, and eliminate the need for specialized personnel to operate machines.

At present, brands such as Desktop Metal, Raise3D, Stratasys, MarkForged, Ultimaker, Prusa, etc. represent the technological level of desktop extrusion metal 3D printing.

Taking chassis components in the automotive industry as an example, such as the control arm of the suspension system. These control arms play a crucial role in vehicle movement, and their internal structure is complex. Traditional manufacturing requires the assembly of multiple components, while desktop metal 3D printers can print components in a single step, thereby shortening delivery time and reducing costs.

Binder jetting metal 3d printing

Binder jetting metal 3D printing technology has attracted attention due to its unique advantages in mass production of parts. One of the notable features of this process is its ability to achieve efficient mass production of metal 3D printing. Compared to traditional laser 3D printers, equipment based on the binder jetting process is not only more cost-effective, but also has faster printing speed, and can even reach dozens or even hundreds of times that of laser powder bed melting equipment.

Meanwhile, the material used is traditional Metal Injection Molding (MIM) powder, which is cheaper than spherical powder, significantly reducing the manufacturing cost of parts. Although the performance of the adhesive spraying process is slightly lower, it performs excellently in terms of cost-effectiveness and can reach a level comparable to injection molded parts. Therefore, this technology is more suitable for achieving the manufacturing of large-scale parts.

What is Metal Injection Moulding (MIM) Process?

At present, major automobile manufacturing companies are accelerating the adoption of binder jetting metal 3D printing technology. Some leading binder jetting metal 3D printing developers have partnered with major brands in the automotive industry.

So, how do these three 3D printing technologies achieve mass production of components from thousands to hundreds of thousands?

Before large-scale production, small-scale production is usually carried out for market testing. Binder jetting metal 3D printing technology has played a significant role in large-scale production through its advantages in mold free manufacturing, eliminating the need for molds. This enables engineers to efficiently use improved designs for production, with fast printing speeds and the ability to produce thousands of components at once. At the same time, Selective laser melting technology and extrusion based desktop metal 3D printing based on extrusion can meet small batch needs in the early stages of production by being adaptable to different scales of flexibility. Laser powder bed melting technology, due to its high precision and complex manufacturing characteristics, is suitable for producing high-end brand components, while desktop metal 3D printing based on extrusion plays a cheap and fast advantage in the early stages of new car design and manufacturing. Overall, the comprehensive application of these three technologies in large-scale component manufacturing provides flexible, efficient, and cost-effective solutions for the automotive industry.

FAQ

In the realm of 3D printing, commonly used metals include but are not limited to titanium, aluminum, stainless steel, and nickel alloys. These metals are favored for their specific properties, such as high strength, corrosion resistance, and lightweight characteristics, making them suitable for various applications across industries.

The primary 3D printing methods employed for printing metals include Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Binder Jetting. These methods utilize different approaches to achieve metal additive manufacturing, each with its own set of advantages and considerations.