Plastic bevel gears are a crucial component in many mechanical transmission systems, particularly in industries where lightweight, low-noise, and cost-effective solutions are required. These gears offer smooth power transfer and can be customized to fit a wide range of applications. Let’s dive into a quick guide on how plastic bevel gears for transmission are made.

Understanding Plastic Bevel Gears

First off, let’s get the basics straight. Bevel gears are a type of gear with teeth that are set at an angle to the axis of rotation. This design allows for power transmission between two intersecting axes, making them ideal for applications where the drive direction needs to be changed. Plastic bevel gears, as the name suggests, are made from plastic materials like nylon, polycarbonate, or high-performance polymers.

How Are Plastic Bevel Gears Made?

Here’s a look at how these gears are made.

Step 1: Material Selection

The first step in making plastic bevel gears is selecting the right material. Common plastics used in the manufacturing of bevel gears include ABS, nylon, PP (polypropylene), PC (polycarbonate), and PVC. Factors like load capacity, operating temperature, and lubrication requirements are considered when choosing the material.

Here are the specific examples and applicable scenarios for several commonly used plastic materials:

- ABS is suitable for low-cost and general strength requirements.

- Nylon, due to its superior performance, is applicable in high-load and complex environments.

- PP is suitable for low-load and low-cost applications.

- PC is often used in situations requiring high transparency and good impact resistance.

- PVC, with relatively low wear resistance, is applied in simple transmission devices.

Step 2: Design and Engineering

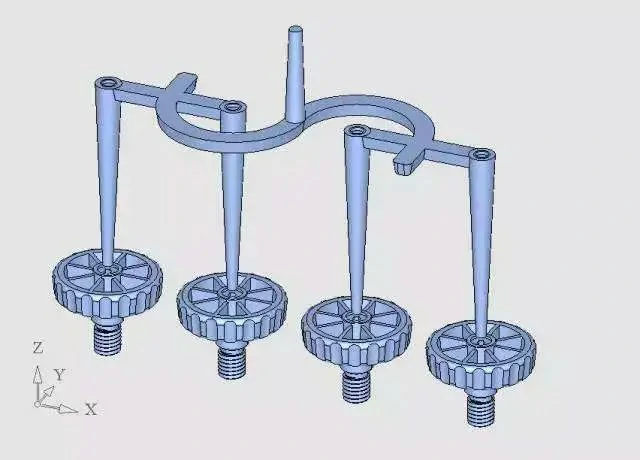

Engineers carefully plan the specifications of the bevel gear, including its size, shape, material, and tooth profile. The design must take into account factors like torque capacity, speed, and backlash reduction to ensure optimal performance. CAD (Computer-Aided Design) software is often used to create detailed 3D models of the gear.

Step 3: Tooling and Mold Making

After the design and material are decided, the next step is to create the mold or tooling used for injection molding. This process involves precision machining to create the negative image of the gear, which will later be used to form the plastic part. Manufacturers often invest heavily in high-precision machinery and skilled technicians to ensure the molds are flawless.

Step 3: Molding

Once the design is finalized and the material selected, the manufacturing process begins with molding. Plastic bevel gears are commonly made using injection molding.

Here’s a step-by-step look at this process:

- The selected plastic material is fed into an injection molding machine, where it’s heated to a molten state.

- The molten plastic is then injected under high pressure into the precision-made mold.

- Once the plastic fills the mold cavity, it’s allowed to cool and solidify.

- After the plastic has solidified, the mold opens, and the newly formed bevel gear is ejected from the mold.

Step 4: Post-Processing

After molding, the gears undergo post-processing steps to enhance their performance and durability. Some gears may also require heat treatment to improve their hardness and wear resistance.

These steps might include:

- Removing excess plastic from the part’s edges or gates.

- Removing sharp edges or burrs left behind from the molding process.

- Checking the gear’s dimensions, tooth profiles, and overall quality using precision measurement tools.

- If the gear is part of a larger assembly, it might be combined with other components at this stage.

Step 5: Quality Control

Quality control is a vital step in the production process. Each gear is inspected for dimensional accuracy, tooth profile, and surface finish. Advanced measurement tools like CMMs (Coordinate Measuring Machines) and laser scanners are used to ensure that the gears meet the required specifications. View BOYI’s quality control flow.

Step 6: Assembly and Testing

Once the gears are manufactured and inspected, they’re ready for assembly into the transmission system. Depending on the application, they may be combined with other gears, bearings, and shafts to form a complete transmission assembly. Before being shipped to customers, the assembly is tested to ensure that it operates smoothly and efficiently.

Applications of Plastic Bevel Gears

Plastic bevel gears find widespread application in various industries, including:

Automotive

In addition to electric vehicles, power steering systems, and transmissions, plastic bevel gears can also be found in small motor applications like window regulators, door locks, and seat adjusters. Their lightweight design contributes to improved fuel efficiency and reduced overall vehicle weight.

Consumer Electronics

Portable devices like smartphones, tablets, and laptops increasingly incorporate small motors and actuators for features like vibration feedback, camera stabilization, and auto-focusing. Plastic bevel gears, due to their compactness and efficiency, are well-suited for these applications.

Industrial Automation

Plastic bevel gears are favored in automation systems due to their resistance to wear and tear, even under heavy loads and high-speed operation. They are also used in packaging machinery, printing presses, and textile machinery, where precision alignment and smooth power transmission are key to efficient production.

What are the Advantages and Disadvantages of Bevel Gears?

Here’s a table presenting the advantages and disadvantages of plastic gears:

| Advantages | Disadvantages |

|---|---|

| Lightweight, reduces load | Limited load capacity, not suitable for high loads |

| Good wear resistance, long life | Poor thermal stability, prone to deformation at high temperatures |

| Self-lubricating, reduces noise | Low surface hardness, susceptible to scratches or wear |

| Corrosion-resistant, suitable for harsh environments | May crack under environmental stress |

| Low processing cost, easy to produce | High coefficient of thermal expansion, affects transmission accuracy |

| Eco-friendly, recyclable | May have lower precision and stiffness compared to metal gears |

| Vibration damping, improves comfort | Not suitable for all transmission systems or scenarios |

| Design flexibility, customizable | May be affected by certain chemical solvents |

What are the Three Types of Bevel Gears?

The three key types of bevel gears are:

- Hypoid Gears – Characterized by an offset axis design, enabling high torque transfer in compact spaces.

- Straight Bevel Gears – Simple, robust design for low-speed, high-torque applications.

- Helical Bevel Gears – Offer smoother operation and quieter meshing due to their spiral tooth arrangement.

What Transmission Uses Bevel Gears?

Differential drives use bevel gears. Differential drives allow the wheels of a vehicle to rotate at different speeds while maintaining traction and stability.

Why are Bevel Gears so Expensive?

The high cost of bevel gears is due to their complex design, the precision required in manufacturing, the use of high-quality materials, and the careful assembly and inspection processes.

Customization and OEM Services

Many manufacturers offer customization and OEM (Original Equipment Manufacturer) services to meet specific customer requirements. This includes designing and producing custom gears based on customer drawings, samples, or specifications. With these services, customers can get precisely what they need, whether it’s a unique tooth profile, specific material, or a particular size.

BOYI provides comprehensive injection molding services and mold manufacturing services to meet the diverse needs of its customers. Customers can collaborate with BOYI’s experienced team to develop custom molds tailored to their specific product requirements, ensuring precise replication of parts with consistent quality and dimensional accuracy.

Ready for Your Project?

Try BOYI TECHNOLOGY Now!

Upload your 3D models or 2D drawings to get one on one support

FAQ

Plastic gears offer several advantages over metal gears, including reduced weight and lower inertia, thanks to the lower density of the material. This makes plastic gears ideal for applications where weight savings and energy efficiency are critical.

The straight bevel gear is the most commonly used type of bevel gear. It features straight teeth and is widely preferred in applications where low speeds and lower torque are required.

No, bevel gears are not always 90 degrees. While bevel gears are commonly used in 90-degree angle configurations, they can be designed for other angles as well. The angle between the shafts of bevel gears can vary, typically ranging from 0 to 180 degrees.

Plastic gears are better for lightweight, low-noise, and cost-sensitive applications. Metal gears are better suited for high-strength, high-load, and high-temperature environments.

For most general applications, acetal (POM) and nylon (PA) are the best materials due to their balance of mechanical properties, wear resistance, and ease of manufacturing.

Using WD-40 on plastic gears is generally not recommended. While WD-40 is a versatile lubricant and solvent, it can have adverse effects on certain types of plastic.

Catalog: Injection Molding Guide

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.