Ever noticed those cool mesh-like metal sheets around? You know, the ones that seem to be everywhere from industrial floors to fancy architectural designs? They’re called expanded metal sheets, and they’re way more than just metal with holes. These expanded metal sheet are used in all sorts of places, from heavy-duty industrial floors to adding a touch of style to buildings.

In this article, we’ll chat about where they’re used, what they’re made of, and why they’re so darn awesome.

What is Expanded Metal Sheet?

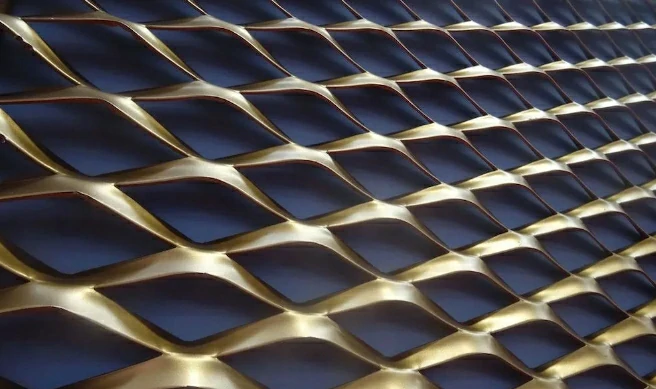

Expanded metal sheet, also known as expanded metal mesh, is a type of sheet metal that has been cut and stretched to form a pattern of open spaces.The slits are oriented perpendicular to the direction of the stretch, resulting in an array of holes that give the material its mesh-like form. This process allows for the creation of a strong and lightweight material that is suitable for various applications.

The concept of expanded metal sheet arises from the understanding that metals have the ability to change their size—expanding and contracting—under different conditions. These changes are primarily influenced by the chemical properties of the metal and the behavior of its atoms.

Expanded metal is distinct from other types of metal sheets, such as perforated metal sheets.

Perforation involves punching holes into a metal sheet, which results in a perforated sheet. While some sheets that can be perforated can also be expanded, there are key differences between the two processes.

Perforation is a subtractive process that removes material from the sheet, which can be considered a disadvantage as it generates waste. On the other hand, expanded metal does not involve the removal of material but rather the stretching of the metal to create the mesh structure.

For more information on perforated metal sheet, please read this article: What is a Perforated Metal Sheet? Uses, Type, and Benefits

Materials of Expanded Metal Sheet

Expanded metal sheets can be made from various materials such as steel, aluminum, stainless steel, copper, or other alloys.

- Steel: Durable, and have high strength properties, making them suitable for heavy-duty applications.

- Aluminum: Corrosion-resistant, and ideal for applications where weight is a concern.

- Stainless Steel: Offer excellent corrosion resistance and are suitable for applications requiring hygiene and cleanliness.

- Copper: Provide excellent conductivity and antimicrobial properties, making them ideal for electrical and HVAC applications, as well as architectural accents.

How is Expanded Metal Sheet Manufactured?

Expanded metal is made from thin metal sheets through mechanical processes such as stretching, and flattening. The modern commonly used method for this is CNC punching and shearing.

CNC punching is a popular method where thin and flexible metal sheets are chosen as raw materials. The punching and shearing process is rapid and efficient, enabling the mass production of high-quality expanded metal. The resulting expanded metal resembles soft textile due to its flexibility and versatility.

Type of Expanded Metal Sheet

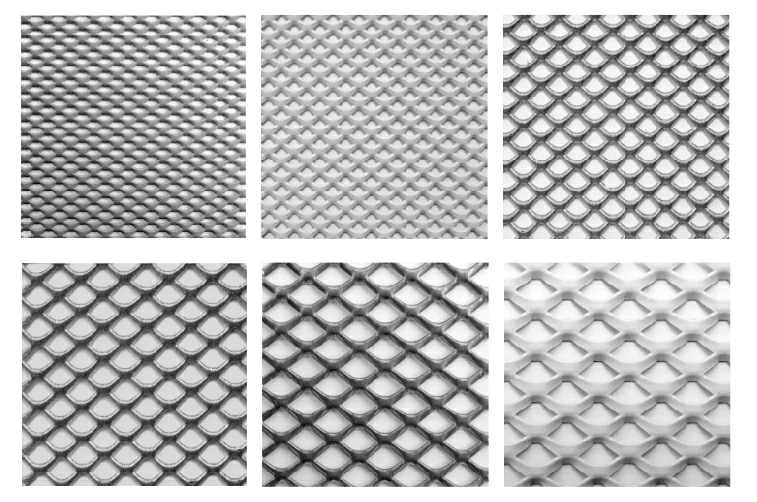

Expanded metal sheet in various types, primarily determined by its material, purpose, and design characteristics:

Classification by Material:

- Aluminum expanded metal sheet.

- Aluminum foil expanded metal sheet.

- Brass expanded metal sheet.

- Copper expanded metal sheet.

- Stainless steel expanded metal sheet.

- Nickel expanded metal sheet.

Classification by Purpose and Specification:

- Small-sized expanded metal sheet.

- Medium-sized expanded metal sheet.

- Heavy-duty expanded metal sheet.

Classification by Grid Type:

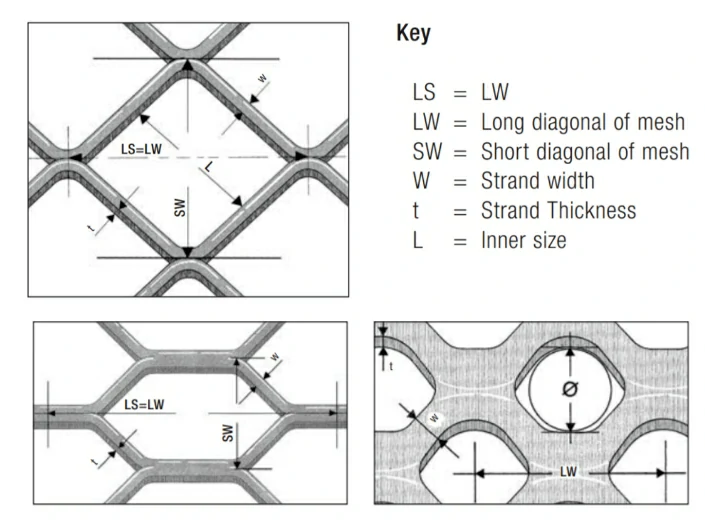

- Square mesh (LS)

- Diamond mesh (LD)

- Other grid types such as hexagonal mesh, circular mesh, decorative mesh, etc.

Surface Finishing of Expanded Metal Sheet

The surface finishing of expanded metal sheets is a critical step that enhances their appearance, corrosion resistance, and longevity.

Common surface finishing processes include PVC coating (spraying, dipping), hot-dip galvanizing, electroplating, anodizing, rust-proof paint spraying, and more.

PVC Coating

This process involves applying PVC powder onto the surface of expanded metal sheets through physical techniques. PVC coating provides excellent waterproofing, chemical resistance, and heat sealing capabilities, while preserving the excellent properties of the raw material polyethylene and offering a controlled release effect.

Hot-Dip Galvanizing

This process entails immersing expanded metal sheets into molten zinc, forming a layer of zinc coating on the surface. This coating effectively protects the expanded metal sheets from corrosion.

The zinc coating features fine, uniform crystallization without porosity, offering excellent corrosion resistance and an elegant appearance, thus adding a decorative touch.

Electroplating

Usually, electroplating involves forming a layer of zinc coating on the surface of expanded metal sheets through an electrolytic process. Similar to hot-dip galvanizing, electroplating also provides good corrosion resistance.

Anodizing

This is an electrolytic process where expanded metal sheets are placed in an electrolyte solution, forming an oxide film on the surface under the action of an external electric current. This oxide film exhibits good hardness, corrosion resistance, and decorative properties.

Anodizing is commonly applied to metals such as aluminum, magnesium, and titanium.

Rust-Proof Paint Spraying

Rust-proof paint is primarily used to prevent expanded metal sheets from rusting and corroding, especially suitable for steel components that have already rusted. It produces a thin protective layer, suitable for rust prevention treatment on high-precision components and fitness equipment surfaces without affecting their precision and normal operation.

Rust-proof paint is an acid-based formula that can quickly and thoroughly penetrate rusted areas. It is water-based, environmentally friendly, and harmless.

Advantages of Expanded Metal Sheet

Expanded metal sheet offers several advantages over other materials, including:

- Lightweight.

- Extremely high strength and durability.

- Elegant and aesthetic appearance.

- Excellent ventilation and transparency.

- Simple installation process.

- Excellent corrosion resistance.

- Recyclable.

- Lower manufacturing costs compared to solid metal sheets.

What Are Some Uses of Expanded Metal Sheet?

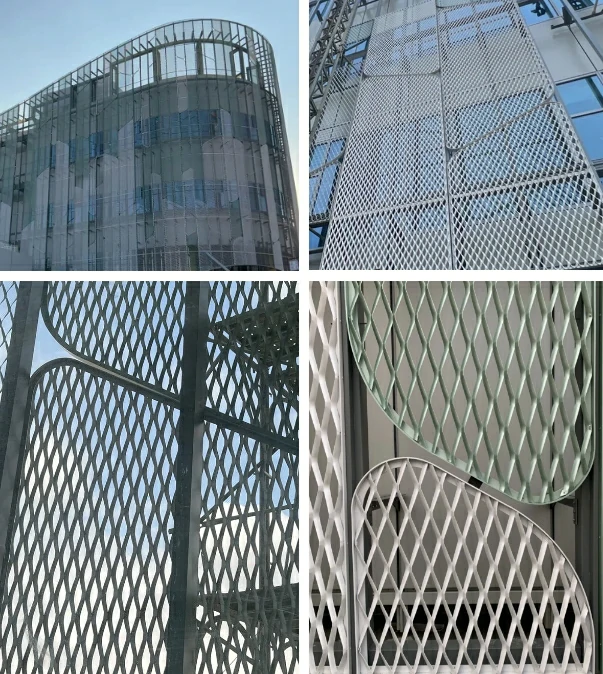

Expanded metal sheet is widely used in space division, wall decoration, screens, windows, and can also be applied to building facades. It possesses unique flexibility and sheen, with a rich and colorful palette, exuding a strong sense of artistic beauty.

Application case:

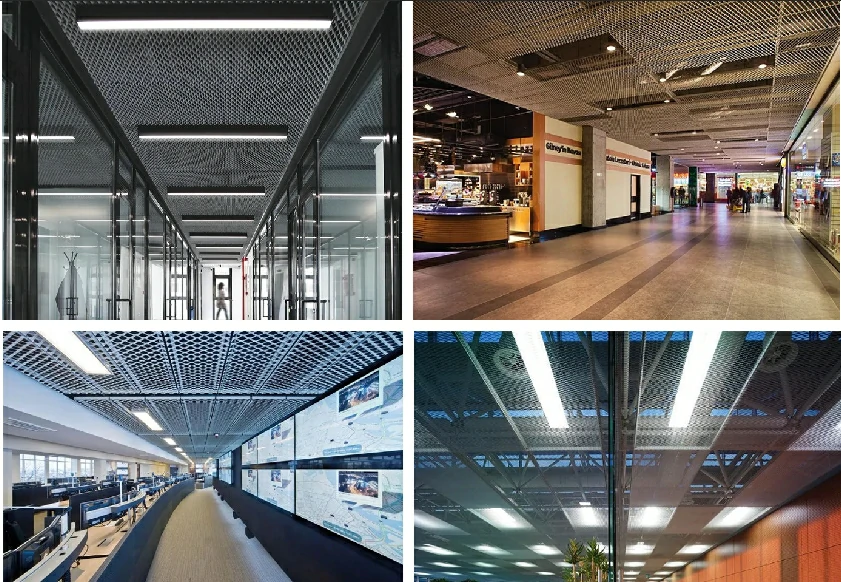

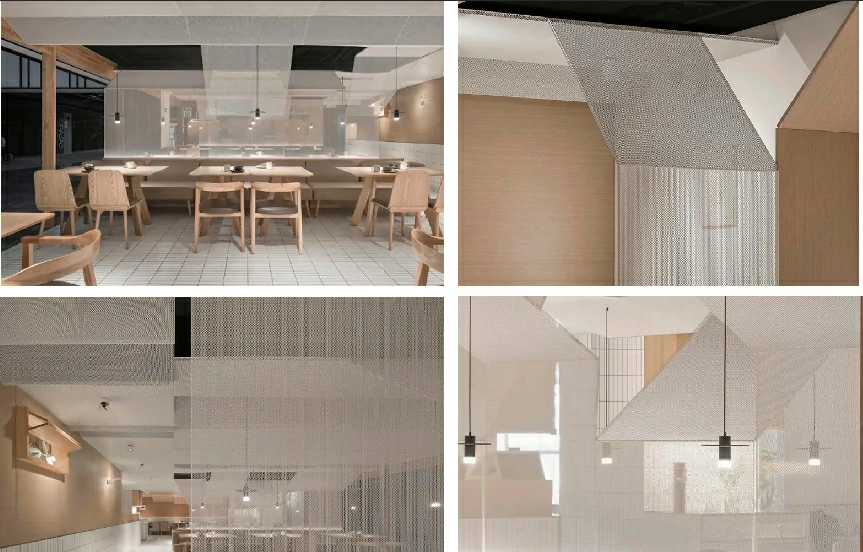

1.Ceiling Decoration

The ceiling is made of stainless steel expanded metal sheet, which is both functional and aesthetically pleasing. Provide protective barriers to prevent damage to hanging lights, exposed wooden ceiling structures.

2.Curtain Wall Decoration

The hollow metal stretching net gives a transparent visual feeling.

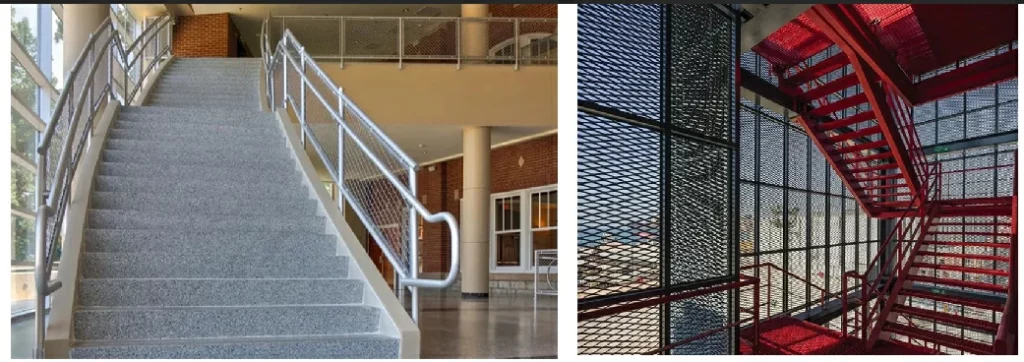

3.Stairs, Balcony Railings

Expanded metal sheet for stair railings is beautiful, low maintenance, cost effective, selected filling materials, flexible, and finishes are available in a variety of different patterns, colors and textures.

4.Interior Decoration

Inside the restaurant, the white expanded metal sheet preserves the permeability of the space, allowing for the shape to be unobstructed from the surrounding view.

BOYI – Your Expert in Expanded Metal Sheet Manufacturing by Your Side

Do you need to purchase an expanded metal sheet? BoYi provides customized expanded metal sheet manufacturing services for you.

BoYi possesses advanced production equipment and a professional technical team, capable of customizing various specifications, mesh sizes, and sheet thicknesses of expanded metal sheets according to your specific requirements.

We promise to fulfill all your needs with the highest quality service and the most reasonable prices. Please contact BoYi now to learn more about our products and services. We are also happy to provide obligation-free quotations.

Put your parts into production today

All uploads are secure and confidential.

Conclusion

In conclusion, expanded metal sheets are versatile materials with a wide range of applications across various industries. Their unique combination of strength, versatility, and cost-effectiveness makes them a preferred choice for numerous structural, functional, and decorative purposes.

FAQ

The common size of an expanded metal sheet is 4 feet (width) x 10 feet (length). This size is very common in many application scenarios, especially in construction, industrial, and commercial applications.

The cost of a 4×8 sheet of expanded metal made from standard materials such as steel or aluminum typically ranges from $50 to $150 USD. However, costs may vary depending on factors such as the material used, thickness, and supplier.

Expanded metal is formed by cutting and stretching a solid sheet of metal, creating a mesh-like pattern of interconnected diamond-shaped openings. In contrast, perforated metal starts as a solid sheet that is fed into a machine to punch holes in a predetermined pattern, typically straight or staggered lines.

Tagged: Sheet Metal Fabrication Guide