Perforated metal sheet are metal panels that consist of a pattern of small holes or shapes throughout the surface, also known by various other names such as perforated sheet, perforated plate, or perforated screen, is a unique type of sheet metal that stands apart from its counterparts due to its distinctive and functional characteristics.

This metal sheet undergoes a meticulous process of either manual or mechanical stamping or punching, often utilizing advanced CNC technology or, in certain instances, precision laser cutting. These processes allow for the creation of a diverse array of hole sizes, shapes, shapes include circles, squares, rectangles, and even more complex designs..

The allure and utility of perforated metal sheets stem from their ability to combine strength with aesthetic appeal. The holes not only provide visual interest but also serve a range of functional purposes.They can enhance airflow, allow light to pass through, or act as filters, depending on the application.This type of sheet metal has a wide range of applications in fields such as construction, decoration, filtration, ventilation, and more.

In this article, we will delve deeper into the world of perforated metal sheets, exploring their manufacturing processes, applications, and the benefits they bring to diverse industries.

Is Perforated Metal Sheet Expensive?

Perforated metal sheet typically does come at a higher price point compared to non-perforated metal panels due to the additional manufacturing processes involved in creating the perforations. Expect to pay anywhere from 50% more to double the cost of non-perforated options.

Factors that can influence the cost include the type of metal used, the size and pattern of the perforations, and the thickness of the metal. Additionally, any special finishes or coatings applied to the perforated metal can also affect the overall cost, reflecting their premium status and added value. Its unique aesthetic appeal and functional benefits often justify the investment for specific applications.

How Are Perforated Metal Panels Made?

The production of perforated metal sheets primarily relies on three common methods: punch press, rotary piercing, and laser cutting. Each of these methods has its unique characteristics and is suitable for creating different configurations, shapes, and forms.

Punch Press

Punch press is a traditional and effective method for fabricating perforated metal sheets. By using precision-designed punches and dies, the machine applies significant pressure to the metal sheet, replicating the hole patterns on the sheet. This method is suitable for mass production, offering high efficiency and relatively low costs. Punch press can create holes of various shapes and sizes, and the arrangement and distribution of the holes can be customized according to specific needs.

Rotary Piercing

Rotary piercing is a highly flexible perforation method. It involves a rotating wheel with multiple pins that continuously impact the metal sheet, creating dense holes. This method excels in fabricating metal sheets with complex patterns and irregular holes. The advantage of rotary piercing lies in its ability to achieve a mixed arrangement of various holes on a single sheet, with adjustable hole diameters and spacings to meet diverse design requirements.

Laser Cutting

Laser cutting is a high-precision and efficient perforation method. It utilizes a high-power laser beam to precisely burn holes in the metal sheet. Laser cutting can create extremely small holes and offers a high level of customization in terms of hole shape and size. Additionally, it is suitable for fabricating metal sheets with complex contours and curves. Although laser cutting equipment can be costly, its precision and flexibility make it an ideal choice for fabricating high-precision perforated metal sheets.

Perforation Methods

The most common perforation method involves the use of CNC and turret punch presses, suitable for mass production and repetitive patterns. Water jet or laser cutting is an ideal choice for creating customized perforations and patterns, offering a variety of hole sizes and unique shapes.

Custom perforation patterns and shapes, produced using millimeter-precision machines and other advanced manufacturing technologies, can also achieve an infinite variety of folded and perforated panel designs.

Type of Perforated Metal Sheet

Perforated metal plates come in the following types:

Classified By Material

According to the different materials used in perforated metal, it can be divided into perforated aluminum, perforated steel, perforated copper, and perforated iron.

Among them, perforated aluminum is the most common, which can undergo surface treatments such as electroplating, spraying, and wire drawing, as well as customization in different colors.

Classified By Perforation Form

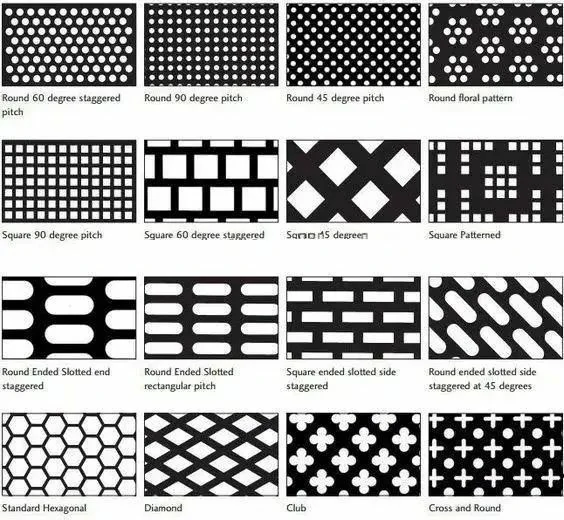

If classified according to the perforation form, perforated panels can be divided into various types such as uniform perforation, gradient perforation, and pattern perforation.

The hole size and pattern design of perforated panels can be finely processed and designed according to actual needs. Different hole sizes, densities, and shapes can create unique semi-transparent visual effects, adding layers and dynamics to the space.

Common hole specifications include: rectangular holes, square holes, diamond-shaped holes, round holes, elongated holes, hexagonal holes, irregular holes, and irregular holes, among other shapes. The arrangement of these holes can also be divided into various layout forms such as orthogonal and diagonal.

With the support of modern CNC machining technology, BoYi can easily draw various special gradient patterns on the sheet. This enables patterned perforated panels to be widely used in architectural design.

Put your parts into production today

All uploads are secure and confidential.

More and more architectural projects use patterned perforated panels as cladding materials, not only enhancing the aesthetics of the buildings but also increasing their artistic and uniqueness.

For example, the new headquarters building of Seoul’s popular music adopts dynamic linear design, as well as perforated patterns and alternating designs of aluminum panels and glass, creating a visual effect of the building’s internal functions and activities appearing and disappearing.

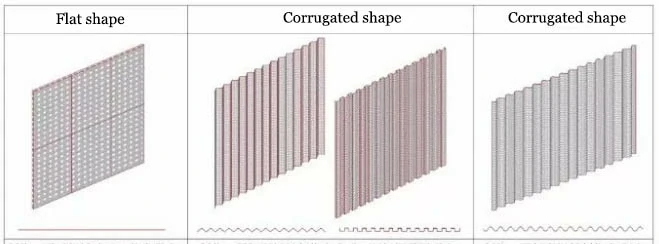

Classified By Sheet Shape

Classified by sheet shape, perforated panels are mainly divided into three types: flat shape, irregular shape, and corrugated (bent) shape.

Flat shape are the most common shape for perforated metal sheet, with relatively simple manufacturing processes and lower material costs.

Corrugated shape are perforated metal sheet that have been bent to form concave-convex or serrated folded panels.

Corrugated shape have a unique visual effect. They can create a more hazy and ambiguous semi-transparent atmosphere, and their softened interface contours blend more easily into the natural environment, giving people a sense of inclusiveness and softness.

What Are The Benefits of Perforated Metal Sheet?

Perforated metal sheet, as a versatile, aesthetically pleasing, and practical building material, possess numerous significant advantages. Here are its main advantages:

Aesthetic Appeal

Perforated metal sheet can be customized to create various shapes and sizes of holes, resulting in visually appealing and artistic effects. Their surface can undergo various treatments such as electroplating, spraying, and brushing, allowing for customization of different colors to meet various design needs.

Additionally, through different grooves and angles, various attractive lines and patterns can be formed, greatly enhancing the building’s aesthetic appeal and visual effects.

Breathability and Heat Dissipation

The small holes on perforated metal sheet can effectively increase the permeability of air and light, ensuring sufficient indoor lighting and good ventilation, thereby contributing to the optimization of indoor environments.

Moreover, the perforations in the panels can also facilitate heat dissipation, improving heat dissipation efficiency and helping maintain stable indoor temperatures.

Sound Insulation and Noise Reduction

Perforated metal sheet exhibit good sound absorption and sound insulation performance, effectively reducing noise levels. In environments where noise disturbance needs to be minimized, perforated metal panels are widely used in decorative materials, indoor soundproofing panels, speaker grille covers, and other fields to enhance acoustic performance.

Strength and Stability

After perforation processing, perforated metal sheet are less prone to scratches and marks on the surface, and they have high load-bearing capacity. Corrugated or bent panels can greatly increase the strength of the panels by increasing the structural thickness, meeting various usage requirements.

Weather Resistance and Corrosion Resistance

Perforated metal sheet , especially perforated aluminum, exhibit excellent weather resistance and corrosion resistance, resisting erosion from elements such as rain, sunlight, etc., maintaining long-lasting aesthetics and performance.

While perforated metal sheet have many advantages, they also have some drawbacks that may affect their effectiveness in certain situations. Here are some main disadvantages:

- Limited lifespan.

- High cost.

- Difficulty in maintenance.

- Limitations in application environments.

What Are Perforated Metal Sheet Used For?

Perforated metal sheet , due to their unique performance and aesthetics, are suitable for various applications. Here are their main application areas:

Construction Industry

Perforated metal sheet can be used for decoration and isolation of building exterior walls, balconies, facades, ceilings, stair handrails, and other parts.

With a variety of appearance designs and colors, perforated metal panels can meet the personalized needs of different customers, adding a unique aesthetic to buildings. Additionally, their good permeability and sound insulation performance contribute to optimizing indoor environments.

Example:

The inner layer is made of aluminum alloy insulated glass, and the outer layer is covered with a perforated aluminum sheet made of imitation stone for shading, which not only achieves the effect of facade texture but also meets the indoor lighting and ventilation needs.

Adopting double-layer perforated aluminum sheet , integrating floodlights while achieving a unified visual effect both inside and outside the building.

The innovative design of the balcony in this apartment below uses perforated aluminum sheet , and the panel system has been fully completed when delivered to the site. It can be installed very quickly and simply, not only with good lighting and ventilation, but also with privacy and anti fall protection guaranteed.

Decorative Building Materials

Perforated metal sheet can serve as various wall materials, including exterior wall insulation materials, indoor ceilings, interior and exterior wall veneers, and background wall veneers. The porous structure of their surface allows light and air to pass through, providing natural lighting and ventilation indoors.

Moreover, perforated metal sheet can be used in various furniture designs, such as office furniture and bedroom furniture, enhancing both aesthetics and practicality.

Example:

The top of the atrium is suspended with perforated aluminum sheet in the shape of clouds, creating a subtle light diffusion effect like thin gauze.

It can filter sunlight while integrating evening lighting. There is a maintenance platform above the ceiling panel, where workers can clean the glass ceiling above or wear safety equipment to replace the lighting fixtures below.

The perforated aluminum sheet on the top of the lobby, combined with a tree shaped projection design, fully embody the philosophy of life and experience an immeasurable sense of life ceremony.

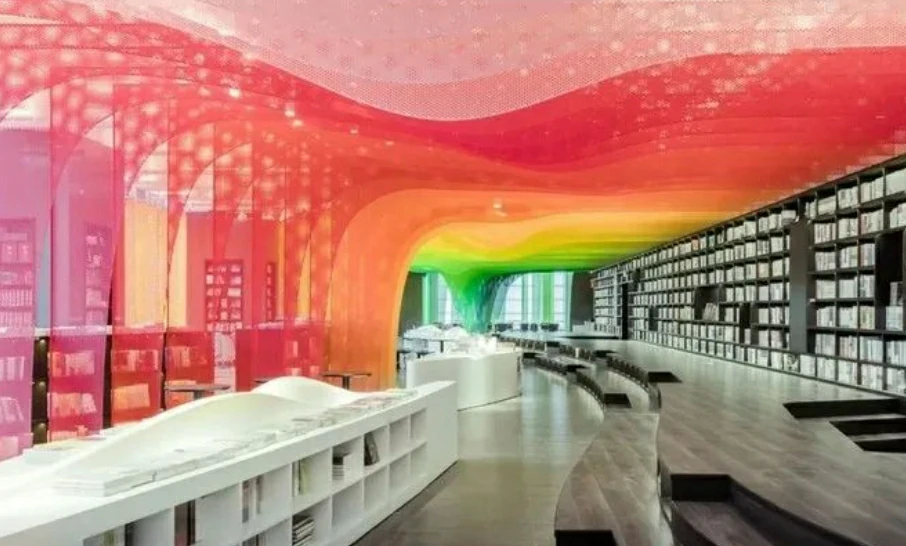

The interior “rainbow” is formed by perforated aluminum sheet with petal patterns. When the perforation rate exceeds 50%, the aluminum sheet visually loses the texture that the metal should have, and the multi-level aluminum sheet is stacked together, like a veil of many layers.

Filtration and Screening

Perforated metal sheet can be used in air filters, gas filters, water filters, and other fields. The hole size and shape can be customized to achieve precise filtration and screening effects.

Other Industries

Perforated metal sheet are also applicable in industries such as electronics, nuclear energy equipment, and automotive manufacturing. In these fields, perforated metal panels are primarily used to achieve functions such as filtration, separation, and isolation, ensuring the normal operation of various equipment.

What is the Alternative to Perforated Metal Sheet?

One of the alternatives to perforated metal sheet is expanded metal. Unlike perforated metal panels, expanded metal is formed by cutting and stretching metal sheet rather than punching holes. This manufacturing method allows expanded metal to minimize waste of raw materials to the greatest extent during production.

Additionally, expanded metal shares similar practical advantages with perforated metal panels, such as good breathability and strength, making it a viable alternative to perforated metal panels.

It’s worth noting that due to differences in manufacturing processes, the appearance and hole shapes of expanded metal may differ from those of perforated metal sheet . Therefore, the selection of which to use should be evaluated based on specific needs.

For more information on expanded metal sheet, please read this article: What is a Expanded Metal Sheet? Uses, Materials, and Advantages

Request a Quotation for Perforated Metal Sheet

Are you ready to kickstart your new project? BoYi perforated metal products will bring you exceptional quality and endless creative possibilities.

With our advanced processing equipment and professional technical team, we can precisely meet your personalized requirements and create unique perforated metal products for you. Start your project now and request our free quotation. Let BoYi be your successful partner! We promise to provide the most competitive prices and the highest quality sheet metal fabrication service to ensure the smooth completion of your project.

Put your parts into production today

All uploads are secure and confidential.

Conclusion

With the continuous advancement of technology and the diversification of demands, the application prospects of perforated metal sheet will be even broader. In the future, they are expected to play a more important role in various fields, bringing more innovation and possibilities to industries.

FAQ

Perforated metal panels are typically cut to size according to application requirements and do not have fixed standard dimensions. Common standard sizes include 48 inches x 96 inches and 60 inches x 120 inches. However, customization is also possible to meet specific design and engineering requirements.

Expanded metal is typically more cost-effective because it generates less waste during the manufacturing process. On the other hand, perforated metal, especially those with intricate and detailed designs, may be more expensive. Therefore, from a cost perspective, expanded metal is generally cheaper than perforated metal.

A wide variety of materials can be used to make perforated metal metal, including steel, aluminum, stainless steel, copper, and titanium, among others. The choice of these materials typically depends on specific application requirements, cost considerations, and desired mechanical and physical properties. For instance, aluminum and stainless steel are often used for outdoor applications due to their corrosion resistance and durability.

The main differences between perforated plate and mesh lie in the distribution of holes, manufacturing precision, and usage. Mesh typically has more openings per square inch, while perforated plate has smaller opening areas, which may affect the throughput. Additionally, perforated plate usually has looser tolerance control compared to mesh. When choosing between them, it is necessary to consider application requirements and scenarios comprehensively.

Perforated metal sheet are lightweight and have high strength. The metal sheet with a thickness of 3.0mm weighs approximately 8kg per square meter, making it lightweight and easy to construct. It has high strength and is safe to use.

Tagged: Sheet Metal Fabrication Guide