When it comes to parts production, the strength and weight of materials become crucial factors to consider. These directly determine the durability and portability of the parts, making the choice between titanium and aluminum particularly important for industries seeking high performance and lightweight solutions.

Nowadays, with intensified market competition, industries are seeking rapid, efficient, and cost-effective methods to drive product innovation. In this process, selecting metal materials with low energy consumption and high processing efficiency is essential. Titanium and aluminum, as two lightweight materials, each have their own characteristics suitable for different industries and applications.

So, what are the differences between titanium and aluminum? What are their respective advantages and disadvantages in terms of performance? How can you choose the appropriate material based on your specific needs? This article will delve into the characteristics, strengths, weaknesses, and applications of titanium and aluminum, aiding you in making informed decisions when selecting materials.

Performance Comparison: Titanium vs. Aluminum

Due to their excellent combination of low density and structural strength, both titanium and aluminum are extensively utilized in fields such as aerospace, automotive, and mechanical manufacturing, whether through 3D printing or CNC machining.

Given that both materials boast high strength and low density, other differentiating factors must be considered when determining which alloy to use.

Let’s compare the characteristics of these two materials.

Element Composition

The elemental composition often directly determines the suitability of titanium and aluminum in specific applications.

Titanium is a multi-element alloy primarily composed of titanium, but it also contains other elements such as hydrogen, nitrogen, oxygen, iron, carbon, nickel, among others. Although the content of these elements is relatively low, typically ranging from 0.013% to 0.5%, they play a crucial role in determining the performance of titanium. For example, certain elements can enhance the strength of titanium, while others may affect its corrosion resistance.

In contrast, the elemental composition of aluminum varies. Aluminum, as its primary component, also contains a variety of elements such as zirconium, zinc, chromium, silicon, magnesium, titanium, manganese, iron, copper, among others. This combination of elements imparts unique properties to aluminum, such as lightweight, good electrical conductivity, and thermal conductivity.

Density and Strength

The density of aluminum is 2.7g/cm³ (one-third that of iron and copper), with good ductility and electrical conductivity two-thirds that of copper wire, while its mass is only one-third, making it inexpensive. Pure aluminum has relatively low density, but aluminum alloy density and hardness are significantly increased.

Titanium has a density of 4.51g/cm3, which is 57% of steel’s density. Titanium is less than twice as heavy as aluminum but has three times the strength. The specific strength of titanium alloys (strength-to-density ratio) is 1.3 times that of aluminum alloys (see Table 1).

Table 1: Titanium vs. aluminum: Density and strength comparison

| / | Aluminum | Titanium |

| Density | 4.5 | 2.7 |

| Strength | 29 | 21 |

Corrosion Resistance

Both titanium and aluminum exhibit excellent corrosion resistance, but upon closer comparison, it becomes evident that titanium surpasses aluminum in this regard.

This is because the corrosion resistance of titanium depends on the presence of an oxide film, which performs much better in oxidizing environments than in reducing environments. Rapid corrosion occurs in reducing environments. Titanium is effectively protected from corrosion in some corrosive environments, especially in acidic, alkaline, and neutral saline solutions, as well as oxidative environments.

In comparison, aluminum is more susceptible to corrosion due to environmental influences. However, new types of food-grade environmentally friendly anti-corrosion coatings provide additional protection for aluminum, maintaining its dominance in industries such as food.

Heat Resistance

Aluminum loses its original properties at around 150°C, whereas titanium alloys maintain good mechanical performance at approximately 500°C. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages.

For example, When aircraft speeds reach 2.7 times the speed of sound, surface temperatures on the aircraft structure reach 230°C. Aluminum alloys become unsuitable at this temperature, while titanium alloys meet the requirements.

Thermal Conductivity

The thermal conductivity of titanium is small, only 1/13 of that of aluminum. Poor thermal conductivity is a disadvantage of titanium, but in some cases, this characteristic of titanium can be utilized (see Table 2).

Table 2: Comparison of thermal conductivity between titanium and aluminum

| / | Aluminum | Titanium Alloy | Pure Titanium |

| Thermal conductivity /W.(mK)-1 | 121 | 17 | 7.5 |

Electrical Conductivity

Electrical conductivity is an important indicator for measuring the electrical performance of materials. We typically use the electrical conductivity of copper as a benchmark to assess the electrical conductivity of other materials.

Titanium has a relatively low electrical conductivity, only about 3.1% of that of copper, meaning titanium’s electrical conductivity is not outstanding. Therefore, titanium is usually not the preferred material for applications requiring high electrical conductivity.

In contrast, aluminum exhibits better electrical conductivity compared to titanium, with a conductivity of 64% of that of copper. This makes aluminum a more suitable choice for projects requiring good electrical conductivity. Whether it’s wires, cables, or other electrical equipment, aluminum can provide reliable electrical conductivity to meet project requirements.

Overview of Titanium

Titanium possesses characteristics of high strength and low density, earning widespread acclaim for its unique corrosion resistance and excellent thermal conductivity.

Different industries leverage the unique properties of titanium in various ways.

After underground mining and refined extraction, titanium primarily manifests in two consumption forms.

With approximately 95% of titanium in the United States being extensively utilized in the form of titanium dioxide (TiO2). This titanium dioxide, renowned for its bright white color and excellent pigment properties, becomes the preferred material in numerous fields ranging from coatings to food coloring agents and cosmetics.

The remaining 5% of titanium is consumed in its metallic form. Although the proportion is small, its usage is highly specialized, meeting the specific demands for titanium metal in certain industries.

In practical applications, titanium samples with a purity of 99.9% have been considered commercial pure titanium, but this still cannot meet all requirements. Therefore, in order to improve the performance of titanium and reduce costs, people usually combine titanium with other elements to form various alloys.

Advantages of Titanium

- High strength, low density.

- Excellent corrosion resistance.

- Resistance to fracture or damage.

- Resistance to deformation or failure.

- Non-magnetic metal, does not interfere with electronic devices and magnetic fields.

- Suitable for manufacturing medical instruments and implants for the human body.

Disadvantages of Titanium

- Higher manufacturing difficulty and cost compared to aluminum.

- Lower modulus of elasticity, prone to deformation.

- Susceptible to hydrogen embrittlement.

Application of Titanium

Titanium is an element with various excellent properties, and therefore has a wide range of applications in various fields.

Aerospace Industry

Titanium alloys are utilized in the manufacturing of aircraft and engines, including components such as forged titanium fan blades, compressor discs and blades, engine cowls, exhaust systems, as well as structural frames like beams and bulkheads in aircraft. Titanium alloy sheet weldments are also employed in artificial satellites, lunar modules, manned spacecraft, and space shuttles.

Medical Industry

Due to its “biocompatibility,” titanium is resistant to corrosion from bodily secretions, non-toxic, and compatible with any sterilization method. It is widely used in artificial hip joints, knee joints, shoulder joints, elbow joints, cranial bones, artificial heart valves, orthopedic fixation clamps, and more.

Automobile Industry

Titanium alloys are used to manufacture chassis and suspension system components such as shock absorber arms, suspension links, and control arms to reduce the overall weight of vehicles, improve handling performance, and fuel efficiency. Additionally, titanium alloys can also be used to manufacture brake system components such as brake discs and calipers.

Consumer Electronics Industry

Used for borders and internal components of products such as mobile phones and watches. Improve the durability and stability of the product.

Overview of Aluminum

Aluminum is a metal that offers an excellent compromise between lightness and strength. It is typically soft, silver-white, and non-magnetic material. It is economical and easy to process, and can also be welded.

Aluminum alloys also possess a very good strength-to-weight ratio and excellent fatigue and corrosion resistance, making them suitable for many applications. Additionally, they have recyclability, thermal conductivity, and electrical conductivity, and are low in toxicity.

For example, aluminum’s strength actually increases without brittleness at low temperatures, making it an ideal material for low-temperature devices.

Advantages of Aluminum

- Compared to titanium, aluminum is more cost-effective.

- It has a low density and is lightweight.

- Excellent electrical and thermal conductivity.

- Aluminum is harmless to the human body.

- It has good sound absorption properties.

- Aluminum is easy to shape and can be used to create various complex shapes.

- Scrap aluminum products can be recycled through remelting.

Disadvantages of Aluminum

- Compared to titanium, aluminum has lower strength.

- Low hardness and easy to wear.

Application of Aluminum

Aluminum is a lightweight, rust proof, and highly conductive metal, which has been widely used in various fields. Here are some of the main applications of aluminum:

Construction Industry

Aluminum is easy to process, durable, and highly corrosion-resistant, and it’s lighter than steel. One of its earliest applications was in the construction industry. This is because aluminum boasts an excellent strength-to-weight ratio, making it a core material for building facade decoration, interior decoration, and door and window manufacturing.

Aluminum alloy frames are highly durable and cost-effective, making them a preferred choice for homes and offices. Using aluminum for window and door frames typically incurs lower maintenance costs than wood, is more affordable, and is more resistant to scratches, cracks, and damage.

Electricity-related applications

Due to its higher electrical conductivity, aluminum alloy conductors can effectively reduce energy loss and save energy.

Aluminum is an ideal material for power distribution networks because it has better electrical conductivity and weight ratio than copper. While aluminum’s conductivity is only slightly more than half that of copper, its weight is only 30% of copper. Aluminum is also cheaper than copper, making it more cost-effective.

Furthermore, aluminum alloy conductors can be used to manufacture rotors for generators and motors to improve motor efficiency.

Transportation Industry

The lightweight properties of aluminum help improve fuel economy. Aluminum materials are widely used in vehicles such as cars and bicycles to manufacture parts, such as the body, frame, wheels of cars, and the frame of bicycles.

Electronics Industry

Aluminum is indispensable in the manufacturing of consumer electronics such as smartphones, computers, as well as transportation vehicles like cars and aircraft. Aluminum combines aesthetics with practicality, appearing both sophisticated and reliable, meeting the basic requirements of electronic products.

Increasingly, manufacturers are turning to aluminum to replace steel and plastic. This is because aluminum is stronger and more reliable than plastic, yet lighter than steel. Coupled with its inherent heat absorption and dissipation capabilities, aluminum is favored by these electronics manufacturers.

Aluminum is primarily used to manufacture casings, brackets, heat sinks, and other components to provide excellent electrical conductivity, thermal conductivity, and aesthetic appeal.

Titanium vs Aluminum: Which Is the Best for Your Project?

Due to the strong and lightweight nature of these two materials, it is important to consider differentiation factors when deciding which alloy to use for manufacturing parts.

Cost

When selecting metals for machining purposes, aluminum offers significant advantages from a production cost perspective.

Both the price and processing costs of aluminum (including CNC machining, 3D printing, etc.) are comparatively low. Titanium, on the other hand, has higher prices and processing costs. However, lighter parts made from titanium can save transportation fuel, and titanium parts generally have a longer lifespan.

Of course, while considering costs, other factors also need to be taken into account. For example, while aluminum may be lower in cost, its strength and corrosion resistance may not match that of titanium.

Machinability Processes

The choice of materials for a project not only determines the final product’s geometric form but also directly influences the manufacturing processes and efficiency.

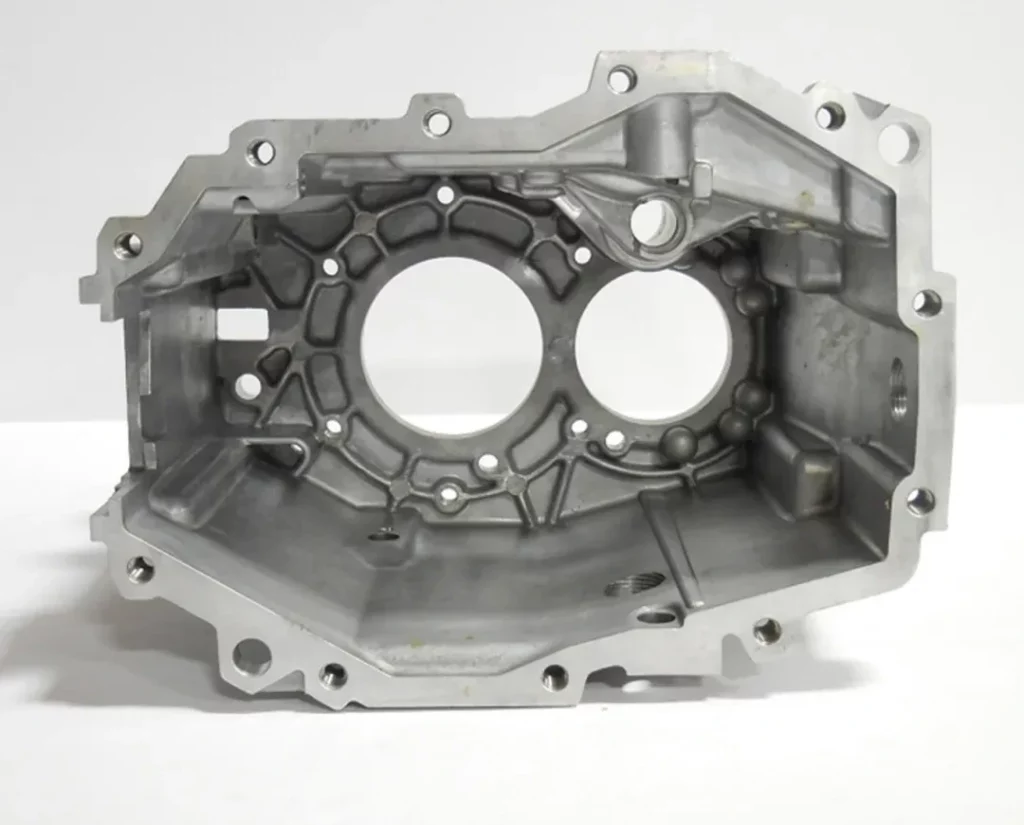

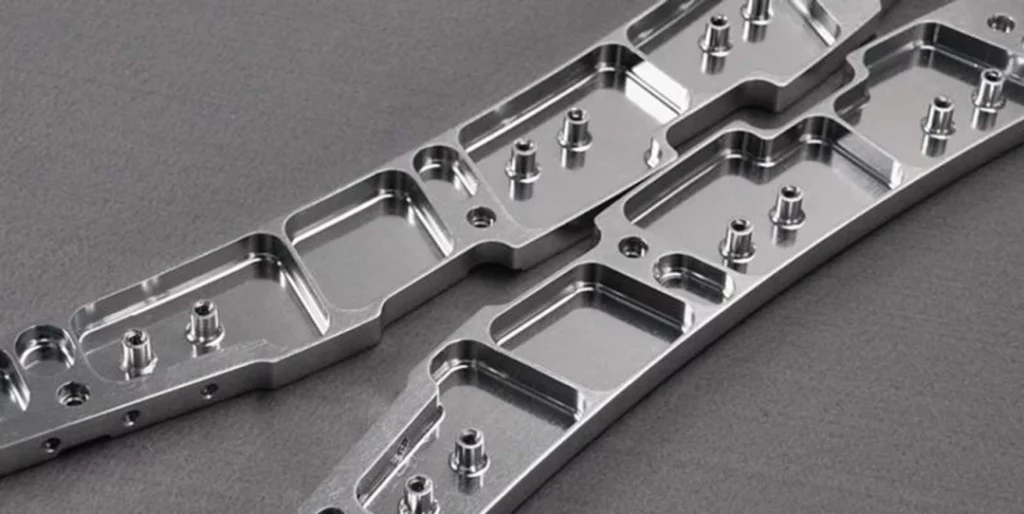

Taking CNC machining and 3D printing as examples, these two processes exhibit significant differences when working with aluminum and titanium metals.

In CNC machining, both aluminum and titanium parts can typically be manufactured in a relatively short time, with tolerances controlled within ±0.1 millimeters. However, CNC machining has certain limitations in geometric shapes, especially when dealing with complex shapes, which may pose challenges.

Additionally, CNC machining generates a certain amount of waste material. While this is not a major issue for the relatively low-cost aluminum, it undoubtedly increases production costs for the expensive titanium. Therefore, in practical applications, engineers should opt to manufacture prototypes using aluminum for testing before switching to titanium for mass production of parts.

In metal 3D printing, the application of titanium and aluminum is more focused on manufacturing complex structures. When parts have complex structures that are difficult to achieve with other processes, metal 3D printing becomes the ideal choice.

For example, complex geometries such as honeycomb and lattice structures are easily realized in metal 3D printing, and these structures often have better performance. Furthermore, when the demand for parts is low, the cost-effectiveness of metal 3D printing is highlighted because it eliminates the need for tooling and the production of large quantities of fixtures, reducing production costs compared to traditional machining processes.

Applications

When selecting metals, it’s essential to consider the product’s operating environment.

If parts need to endure harsh environmental conditions or meet specific strength or weight standards, then titanium may be the better choice. However, if cost is a key factor and the product’s performance requirements are not extremely high, then aluminum may be a more economical option. Additionally, aluminum is a good thermal conductor, making it ideal for use in heat sinks.

Strength and Weight

More importantly, does your product strive for high strength and lightweight?

When pursuing both robustness of components and the importance of every gram in weight, titanium is undoubtedly the preferred material. Especially in medical components, complex satellite parts, as well as fixtures and fastening devices.

Aesthetic Requirements

In project design, the surface finish of metal materials directly affects the final appearance and texture of the product.

Titanium is renowned for its unique silver color, which appears more profound under lighting, giving a sense of nobility and austerity. This characteristic makes titanium particularly popular in product designs that require a high-end, technological feel.

In contrast, aluminum surfaces typically exhibit a silver-white color, relatively uniform in appearance. However, through various surface finishing techniques such as anodizing and painting, aluminum can display a wide range of colors and textures, ranging from silver to dark gray. This versatility makes aluminum more advantageous in applications that require more color choices and personalized designs.

Conclusion

Titanium and aluminum, as two core metal materials in the prototype industry, each possess unique characteristics, hence being widely utilized across various industries. This article has thoroughly explored the differences between titanium and aluminum. If you still encounter questions or confusion during the material selection process, the BOYI team is ready to provide professional guidance and advice at any time. We have abundant experience and expertise to recommend the most suitable metal material based on your specific requirements. Please feel free to contact us anytime.

Put your parts into production today

All uploads are secure and confidential.

FAQ

The most common types of aluminum alloys are 6061, 7075, 5020 and 8020 aluminum. 6061 aluminum is the most widely used alloy, with a good balance of strength, corrosion resistance, and machinability.

Whether aluminum or titanium is better depends on specific project requirements. Aluminum offers superior thermal and electrical conductivity, as well as easier machinability, making it ideal for certain applications. Titanium, on the other hand, boasts exceptional corrosion resistance and a high strength-to-weight ratio, but its higher cost and machining difficulty can limit its use.

No, Titanium is significantly harder and more scratch-resistant than aluminum. With a hardness rating of 6 on the Mohs scale, titanium outperforms aluminum, which typically falls within a rating of 2.5 to 3. This means that titanium is more durable and less prone to scratching compared to aluminum. Therefore, if scratch resistance is a key concern, titanium would be the preferred choice.

Titanium generally lasts longer than aluminum. This is due to titanium’s superior strength, corrosion resistance, and durability. Titanium is often used in demanding applications such as aerospace, medical implants, and marine environments where its longevity and reliability are crucial.

Tagged: Materials Guide