The work of CNC machine operators is directly related to the manufacturing of high-precision parts and the improvement of production efficiency. This job not only requires proficiency in complex mechanical operations, but also a profound understanding of digital programming and automated processing.

What is a CNC machine operator?

CNC machine operator is a professional technical position mainly responsible for operating CNC machine tools for machining and manufacturing work. CNC machine tool is a type of machine tool that controls tools through pre-set programs and can automatically complete complex machining tasks.

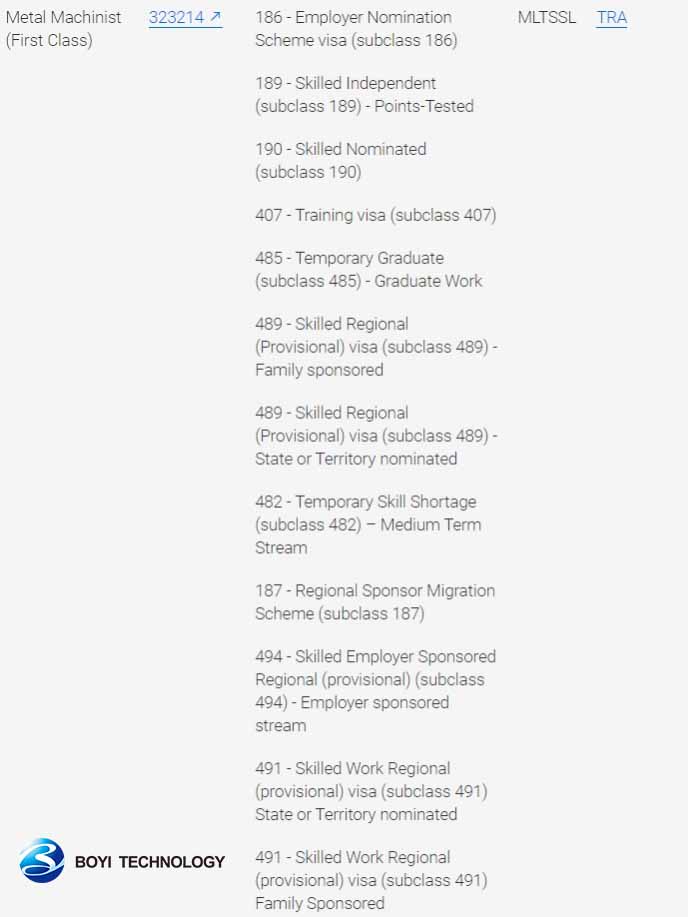

The CNC machine operator this is a blue collar job that leans towards machinery, such as in the local manufacturing industry in Australia, where CNC machine tool operators are very popular. CNC machine tool operators can go through technical immigration programs 189, 190, and 491, as well as employer guarantee programs 186, 482, and 494.

Is it hard to be a CNC operator?

Becoming a CNC operator requires learning specific skills and gaining experience, but it’s not necessarily hard for everyone. Like any profession, it depends on individual aptitude, training, and experience. Some people may find the technical aspects challenging, such as understanding machine programming and troubleshooting, while others may excel in these areas.

CNC machine operator job description

As a CNC (Computer Numerical Control) Machine Operator, you will be responsible for setting up, operating, and maintaining CNC machines to produce precision parts and components according to specifications. You will work in manufacturing environments, ensuring the efficient and accurate operation of CNC equipment to meet production targets and quality standards.

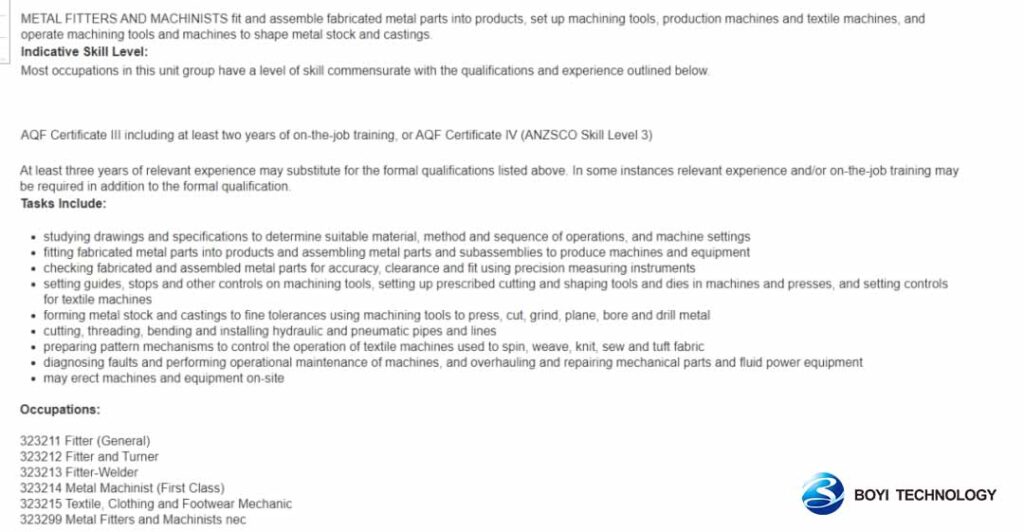

1.Study drawings and specifications

CNC machine operators are first responsible for carefully studying technical drawings and specifications. They need to determine the appropriate materials, operation methods and sequences, and the correct machine setup. This includes understanding the product’s design requirements and manufacturing processes.

2.Assemble metal parts

Operators assemble metal parts into the final product. This may involve assembling metal parts and sub-assemblies to produce precision parts for various machines and equipment. The precision and accuracy of the assembly are crucial to the quality of the product.

3.Use precision measuring instruments to check parts

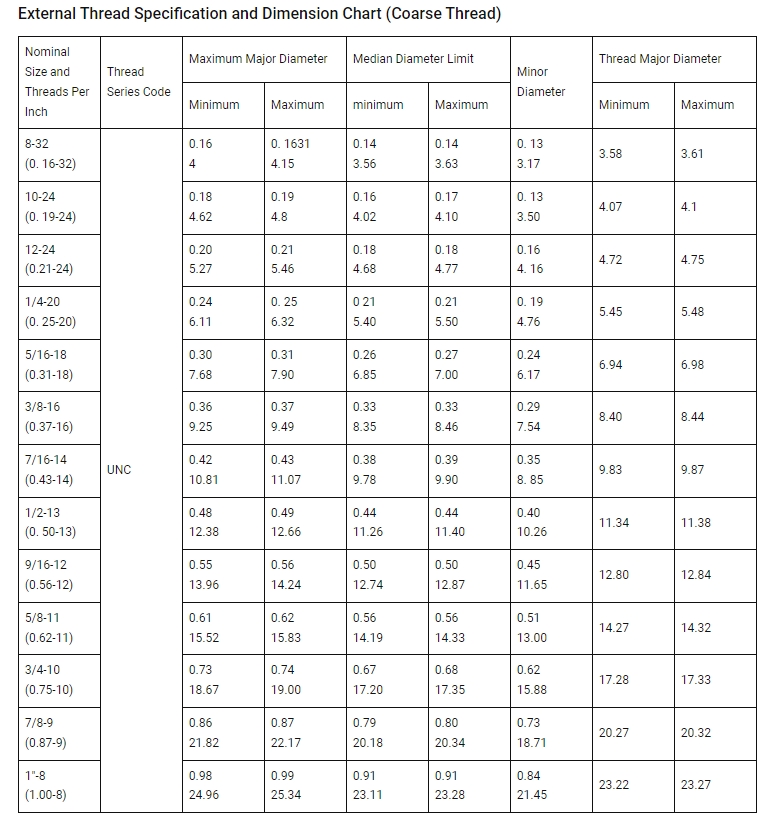

To ensure product accuracy, clearance and fit, CNC machine operators use precision measuring instruments to carry out detailed inspections of fabricated and assembled metal parts. This helps to ensure that products meet strict quality standards.

4.Set up machining tools and controls

The operator is responsible for setting rails, stops and other controls on the machining tools. They also set the prescribed cutting and forming tools and dies in the machine and press, as well as set the controls of the textile machinery to ensure that the entire process is carried out according to the predetermined requirements.

5.Develop metal forming

Using machining tools, operators shape metal blanks and castings to fine tolerances. This may include pressing, cutting, grinding, planing, drilling and drilling metal. These processes require a high degree of technical skill and attention.

6.Install hydraulic and pneumatic piping

CNC machine operators are responsible for cutting, threading, bending and installing hydraulic and pneumatic pipes. These pipes and pipes are essential for the proper operation of machines and equipment, and operators need to ensure that they are installed in accordance with technical specifications.

7.Fault diagnosis and maintenance

CNC machine operators are responsible for diagnosing faults during machine operation and performing necessary operational maintenance. They are also involved in the overhaul and repair of mechanical parts and fluid power equipment, ensuring the normal operation of equipment for a long time.

8.Erection of machinery and equipment on site

Sometimes, operators may need to set up machines and equipment in the field. This includes installing and commissioning the mechanical system to ensure that it functions properly in the actual working environment.

Salary of CNC machine operators

The salary level of CNC machine operators is influenced by various factors, including work experience, skill level, location, and industry demand. In general, the CNC machine operators salary is relatively high because it is a technology intensive job.

In some developed countries, the annual salary of CNC machine tool operators usually ranges from $30000 to $60000, and the specific figures may vary. Meanwhile, operators with richer work experience and higher skills often receive higher salaries.

Qualification requirements for CNC machine operators

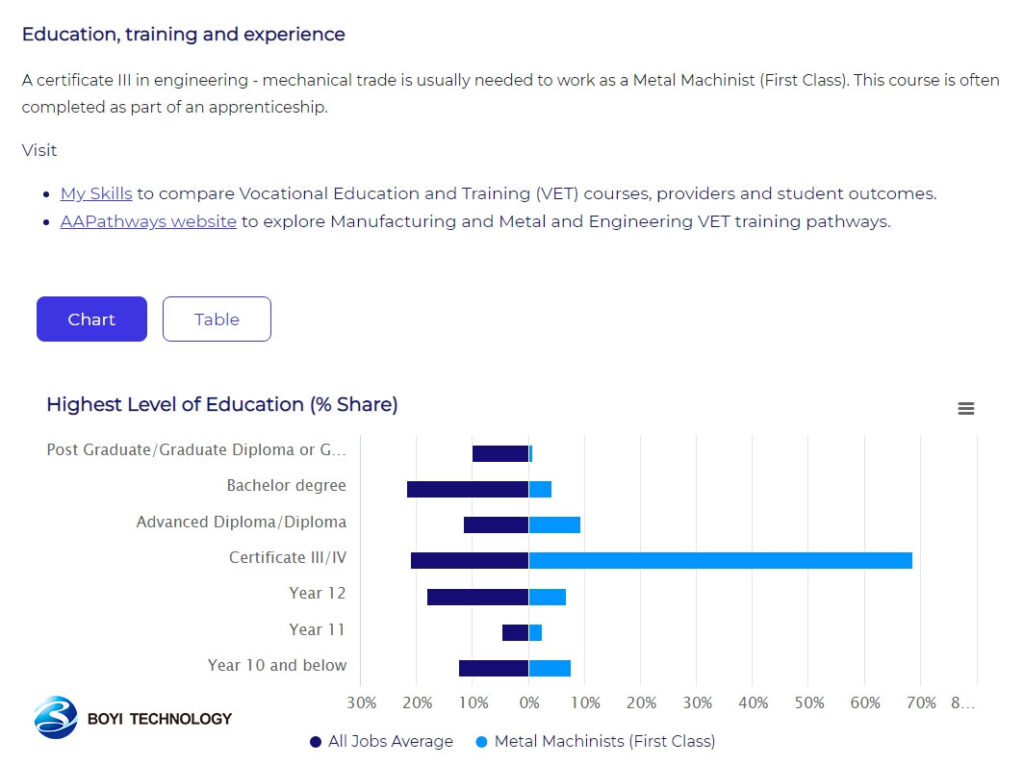

Working as a machine tool operator usually requires a Level 3 certificate in engineering machinery training and at least a secondary education level, usually a high school diploma or equivalent. Training in construction machinery is also required, covering knowledge of CNC machine operation, programming, tool settings, and machine maintenance. During the training period, students may learn skills related to metal processing, mechanical assembly, etc. But this course is usually completed as part of the apprenticeship.

How to become a CNC machine operator?

For those who are new to CNC machine tools, mastering certain CNC machine operation skills is very important. On the one hand, they can avoid machine tool collision accidents, which can lead to machine tool damage; The second is to be able to quickly improve the operator’s CNC machine operation skills and be competent in their job in a relatively short period of time.

1.Understand basic knowledge and theory

CNC machine operation is not just a simple button pressing process. In order to operate CNC machine tools effectively, it is first necessary to have a deep understanding of the basic knowledge of CNC technology. This includes but is not limited to:

Principle of CNC: Understand how CNC works, from its basic input-output relationship to complex interpolation algorithms.

Mechanical structure and kinematics: Understand the mechanical structure of CNC machine tools, including the working principles of each axis, and how they work together to complete machining tasks.

Fundamentals of Materials Science: In order to better select cutting tools and optimize machining parameters, it is necessary to have a basic understanding of materials science knowledge.

Fundamentals of Computer Science: As modern CNC systems are mostly based on computer technology, a basic understanding of computer systems is also necessary.

You can acquire these basic knowledge by reading relevant textbooks, attending training courses, or using online learning resources.

2.Proficient in CNC machine operation skills

You need to master the operation skills of CNC machine tools proficiently. This includes controlling the movement of various CNC axes of the machine tool, as well as mastering the methods of program editing and parameter compensation proficiently. This step not only involves basic operation of the machine tool, but also involves a deep understanding and mastery of the machining process, safety regulations, and problem-solving methods.

This helps to:

Familiar with operating interface: Each CNC machine tool has its unique operating interface and toolbar. Through practical operation, operators can quickly familiarize themselves with these interfaces, understand the functions of various buttons and knobs, and how to perform basic machine operations.

Master the basic operation process: from starting the CNC machine tool, importing the machining program, calibrating the origin to starting the machining, each step has its own specific operation process. Through multiple practices, operators can proficiently master these processes to ensure the smooth progress of the processing.

Safety simulation training: In the simulation environment, operators can simulate various unexpected situations, such as tool breakage, workpiece flying out, etc., and learn how to safely and quickly respond to these situations, ensuring that they can calmly handle various problems in actual processing.

Processing process simulation: Through simulation software, operators can simulate the complete processing process, from raw materials to finished products, and each step can be simulated. This helps operators to identify potential issues in advance and optimize them.

3.Improve processing skills

In the actual processing process, you need to constantly improve your processing skills. This includes careful preparation, understanding drawings, confirming machining accuracy tolerances, and understanding the tool characteristics of different materials, as well as how to choose suitable tools according to machining requirements.

Nowadays, most advanced CNC machine tools are equipped with PC workstations for programming or simulation. So beginners can first perform software editing and machine tool cutting simulation learning on the workstation.

4.Keep learning and improving

Finally, becoming a good CNC machine operator requires continuous learning and improvement. With the constant updating and development of technology, you need to always keep learning attitude and master the latest technology and knowledge. You can keep up with the latest technologies and developments by attending professional forums, attending academic conferences, or reading the latest professional journals. At the same time, you also need to improve your skills and abilities through continuous practice and review.

By leveraging these methods, you can easily find CNC machine shops near you to fulfill your manufacturing needs.

What is the difference between CNC machinist and CNC machine operator?

There are some differences between a CNC mechanic and a CNC machine operator, and although there is some overlap between the two positions, their job responsibilities and skill requirements are different.

The CNC machine operator is mainly responsible for operating the CNC machine to ensure that the parts are produced to meet the requirements. They need to understand the basic principles and operation methods of CNC machine tools, be able to program and adjust according to processing requirements, and ensure the normal operation of machine tools and the stability of processing quality.

However, CNC machinists not only need to have the basic skills of CNC machine operators, but also need to have a deeper knowledge of machining and manufacturing. They are usually responsible for a wider range of machine building and machining tasks, including design, process formulation, machining and inspection. In addition, CNC mechanics also need to have a high level of problem solving and troubleshooting skills, able to deal with complex mechanical manufacturing and processing problems.

However, in contrast, it is relatively easy to learn the operation of CNC machine tools, because it mainly involves the basic operation and processing process of CNC machine tools. Numerical control mechanics need to have more in-depth knowledge of mechanical manufacturing and processing, as well as higher problem-solving ability and practical experience, so the learning difficulty is relatively large.

Conclusion

Overall, to become an excellent CNC machine tool operator, it is still necessary to master certain basic knowledge, operational skills, and machining skills. Through continuous learning and practice, as well as continuous training and improvement, CNC machine tool operators can continuously improve their skills and abilities, creating more value for the company and customers.

FAQ

Yes, being a CNC operator can be a good career choice due to high demand, job security, good pay, opportunities for advancement, skill development, and job satisfaction.

The basic knowledge that CNC machine tool operators need to learn includes mechanical drawing, mechanical manufacturing fundamentals, metal materials and heat treatment, tolerance fitting and measurement technology, CNC machining technology, etc.

CNC machine operators set up, operate, and maintain computer-controlled machines for manufacturing. They load materials, run programs, monitor operations, check quality, and perform basic maintenance.