With the development of manufacturing, CNC machining technology has penetrated into various industries, especially the growing demand for high-end machine tools such as high-speed, high-precision, and five axis linkage machining. CNC machine tool host technology is moving towards high-speed, high-precision, high reliability, high stability, multi axis linkage and composite, flexibility, greenness, intelligence, and other directions.

Many people often face the dilemma of choosing overseas suppliers when searching for metal CNC machine shops near me. These suppliers promise low costs but cannot guarantee quality and timely delivery.

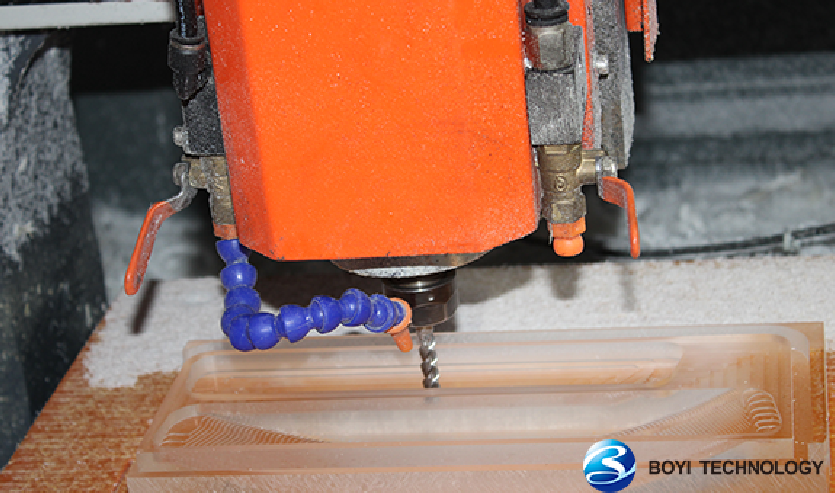

Boyi Technology has always been a leader in the field of high-quality metal and plastic CNC parts. With over 20 years of experience, we are located in Dongguan, Guangdong, China, covering an area of 8000 square meters and possessing a large number of advanced CNC machine tools. This means that when you need reliable and precise CNC parts, Boyi Technology can provide you with a fast and reliable delivery cycle.

We are not only a CNC machine shop, but also a team dedicated to providing customers with excellent solutions. Our craftsmanship is exquisite and the quality is reliable. Regardless of the scale of your project, we will treat it with a professional attitude to ensure that your needs are met.

Visit our CNC machine shop

In our CNC machine tool workshop, you will find a series of impeccably maintained machines, including tools for ultra precision cutting and excellent quality control equipment. We have numerous cutting-edge CNC machine tools, including CNC milling, CNC turning, CNC grinding, and CNC drilling functions.

The 5-axis CNC milling machine we have introduced has excellent processing capabilities, capable of handling complex geometric shapes, strict tolerance control (+/-. 01), and a surface finish of up to 125Ra. Whether it’s handling the toughest metals or advanced plastics, our CNC machines can easily handle them and can also process materials up to 158 inches in length.

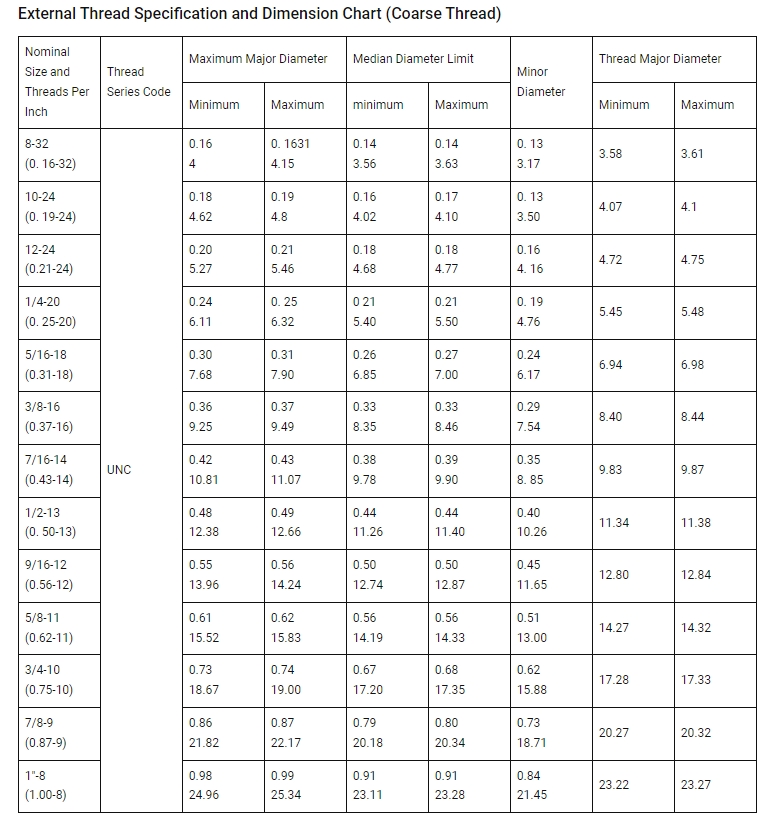

In terms of CNC turning, our multi axis lathe machining technology is particularly outstanding, capable of processing various threads. In addition to metals and plastics, iconic strict tolerances can also be achieved on the most advanced composite materials or wood.

We have experienced professionals who can evaluate your project and assist in making design changes to optimize performance. We also provide material selection recommendations to ensure that your CNC parts arrive on time with each delivery. For emergency situations, we provide emergency production and delivery services to ensure that your parts are assembled and ready for immediate use upon delivery.

By choosing us, you will receive highly precise and reliable CNC machining services to meet the various needs of your project. We are committed to providing customers with excellent solutions, whether in design support, quality control, or delivery services.

Boyi CNC machine equipment

Boyi’s CNC machine tool equipment is an efficient, high-precision, and highly reliable equipment that has been carefully designed and manufactured, capable of meeting the processing needs of various complex parts.

CNC milling

Our CNC milling machine is equipped with advanced CNC system and high-quality spindle motor, which can achieve high-speed cutting and efficient machining. And it can handle complex geometric shapes and meet strict tolerance requirements. They are typically used for processing metals and other hard materials to achieve the desired shape and size.

The characteristics of CNC milling:

Efficiency: Milling is an intermittent cutting method, where the thickness and area of each cutting edge during the milling process vary, resulting in a higher metal removal rate and high production efficiency.

Flexibility: Milling can process various materials, including metals, plastics, etc. It can also handle complex geometric shapes, such as inclined surfaces, curved surfaces, etc.

Strong applicability: Milling is widely used in the fields of molds, mechanical parts, aerospace, etc., and has good adaptability for complex or difficult to control size parts.

CNC turning

Our CNC lathe adopts high-precision ball screws and linear guides to ensure machining accuracy and surface quality. Capable of handling various threads, particularly outstanding in CNC turning.

The characteristics of CNC turning:

High precision: Turning machining has high machining accuracy and can meet the machining needs of workpieces with strict requirements for size, shape, and position.

Machinable complex surfaces: By changing the movement path and speed of the lathe coordinate axis, machining parameters such as cutting angle, depth, and speed can be effectively controlled, thereby achieving the machining of complex parts.

Widely applicable: Turning can process various materials, such as steel, non-ferrous metals, etc., and is suitable for processing different types of parts, such as shafts, discs, etc.

5 axis machining

Our 5-axis machining technology not only has the functions of conventional CNC machine tools, but also enables simultaneous control of five axes. This type of equipment is particularly suitable for handling large or irregularly shaped CNC parts.

Characteristics of 5-axis machining:

Ability to deal with complex geometry: 5-axis machining can carry out complex design and geometric detail processing, by rotating the table or the tool, to achieve multi-angle cutting, processing more complex geometry.

Improved machining accuracy: 5-axis machining reduces errors caused by multiple clamping and improves machining accuracy by machining parts in a single setting.

Shorten the processing cycle: Because multiple surfaces can be processed in a single clamping, the tool change and adjustment time is reduced, thus shortening the entire processing cycle.

Strong applicability: 5-axis machining is not only suitable for the processing of complex parts, but also for the processing of large or heavy parts, because it can reduce the number of clamping and transportation.

These CNC machining services are not only suitable for general parts production, but also widely used in aerospace, medical equipment, automotive manufacturing and other high-end fields. Based on our experienced team, advanced equipment and strict quality control, we provide our customers with high quality customized parts.

Seek CNC machine shop near you? Select Boyi

Boyi CNC Machine Shop provides excellent CNC machining services, dedicated to meeting a variety of complex and demanding machining needs. Our professional team and advanced equipment ensure that you get high quality, efficient CNC parts.

Whether you need to produce hundreds or thousands of high-performance CNC parts, or you need to work with state-of-the-art metal and plastic materials and complex geometrics-we have you covered. We use a strict quality control system, and all CNC parts are ISO quality checked before shipping to ensure full compliance with your specifications.

In order to provide you with an accurate quote, we need to know the following information:

Material type and specification: Different material types and specifications have an impact on the cost and difficulty of processing. Please provide the type and specifications of the materials you need to process so that we can better assess the cost and feasibility of processing.

Number of parts: The number of parts determines the processing time and cost. Providing part numbers helps us estimate machining time and cost.

Accuracy/tolerance requirements: Accuracy/tolerance requirements are key factors in CNC machining. Please provide detailed accuracy/tolerance requirements so that we can assess the difficulty of machining and ensure that your requirements are met.

Parts finishing: Parts finishing involves polishing, deburring and other treatments on parts to achieve high-quality surface effects. Please provide your part finishing requirements so that we can take care of the details for you and ensure that the final product meets your expectations.

Providing the above details in advance will help us respond to you with an accurate quote more quickly. Please rest assured that we will do our best to meet your needs and provide you with the best quality service.

If you have any questions about our services or need pricing, please feel free to send an email to [email protected] . Looking forward to working with you to provide excellent solutions for your project.

FAQ

The cost of CNC machining varies due to various factors, including material type, machining difficulty, number of parts, accuracy requirements, etc. Therefore, it is difficult to provide an accurate hourly processing cost.

Generally speaking, the cost of CNC machining includes equipment depreciation, tool costs, electricity consumption, worker wages, maintenance expenses, etc. In addition, processing complexity, material hardness, cutting speed, and cutting depth can also affect processing costs. Therefore, for specific CNC machining costs, it is necessary to comprehensively consider various factors and conduct detailed cost analysis and quotation

When considering whether it is worth buying a cheap CNC machine, here are some specific suggestions:

1.Clear requirements: First of all, you need to clarify your processing needs. If you only need to make simple straight cuts, an entry-level CNC machine may be sufficient. However, if you need to do complex surface machining or high-precision machining, then you need a more high-end CNC machine.

2.Research machine tool performance: When selecting CNC machine tools, it is necessary to carefully study the performance, accuracy, stability and other indicators of different models. These indicators will directly affect the quality and efficiency of your processing. If your budget allows, choosing a machine with stable performance and high accuracy is a better choice.

3.Compare price and value: The price of CNC machine tools varies depending on the brand, features, quality and other factors. When comparing prices, consider the value of the machine. Although some high-end CNC machine tools are more expensive, they usually have higher accuracy and longer service life, which will provide better protection for your long-term processing needs.

4.Consider later maintenance and upgrades: When purchasing a CNC machine, you also need to consider later maintenance and upgrades. Some brands of CNC machines may be more convenient and economical in terms of maintenance and upgrading. When purchasing, it is necessary to take into account the future development needs and choose the machine tool that can meet the future upgrade needs.

5.Refer to professional advice: If you are not familiar with CNC machine tools, consider consulting a professional mechanical engineer or CNC machining service provider. They can give you more specific advice and help to help you make more informed decisions.