Injection molding is an ideal process for economically and efficiently mass-producing plastic parts. If you are planning to launch a new plastic injection molding project, understanding the cost structure of injection molding and how to accurately estimate costs becomes crucial. This not only helps ensure the economic viability of the project but also allows you to establish a reasonable market pricing for your product.

This article will delve into the cost components of injection molding and analyze the key factors influencing these costs. By understanding these factors, you will be able to more accurately estimate the costs of your injection molding project and develop a sensible pricing strategy for your product.

Injection molding cost: Overview

Injection molding is also divided into metal injection molding and plastic injection molding, in the manufacturing process of plastic products, it efficiently produces plastic products with complex shapes and precise dimensions, but it also involves higher costs.

For example, when a company needs to produce phone cases using injection molding technology, they may choose PC (polycarbonate) plastic, which is known for its strength, durability, and impact resistance. However, the cost of PC materials is relatively high ($2.3 per pound), resulting in material costs accounting for a significant portion of the total cost. To reduce costs, we would suggest considering using ABS material instead of PC ($1.3 per pound). ABS is a high-strength, general-purpose engineering plastic.

The key factors constituting the cost of injection molding

The cost of injection molding involves multiple aspects, and to maintain competitiveness in the market, businesses need to have a thorough understanding of the cost components of injection molding and implement effective measures for cost control. Here are the key factors you need to pay attention to:

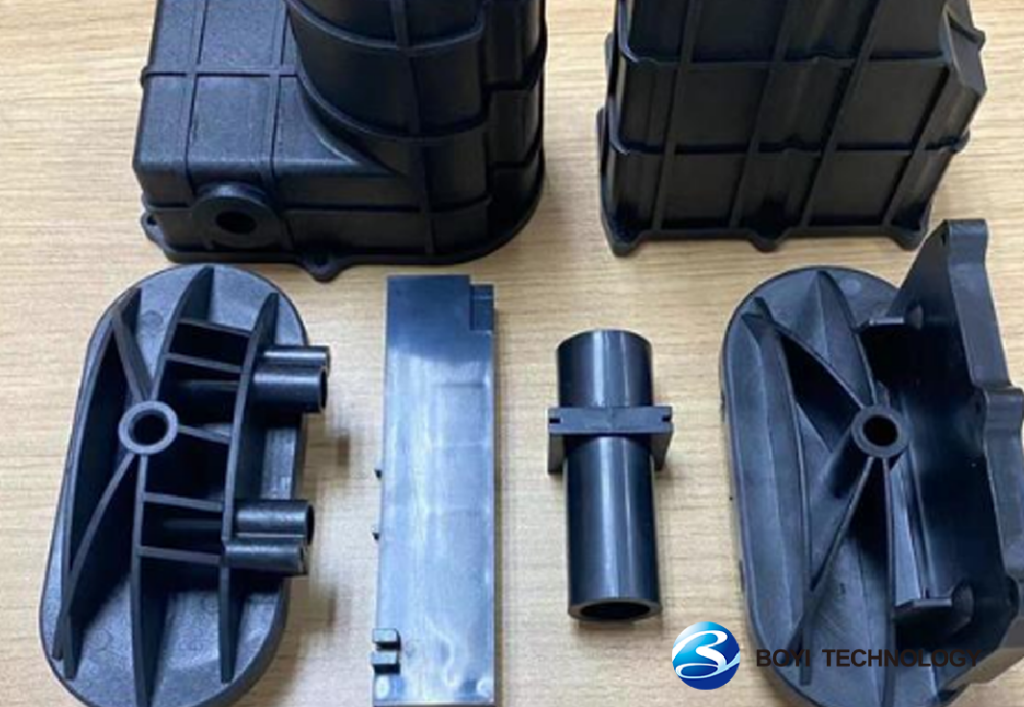

1.Cost of plastic parts

The cost of plastic parts is affected by a number of factors, of which size, design, production and volume are the most critical factors. Understanding how these factors affect injection molding costs helps us better optimize project costs.

Part size

The larger the plastic part to be made, the larger the mold to hold the plastic part, and larger mold designs are usually more expensive than making smaller molds of the same design. Among other things, they require more materials, finer processes, and longer manufacturing times

Part design

Part designs with complex geometries require more complex molds to produce. Mold design usually includes A side and B side. The A-side, also known as the decorative surface, is the surface that the user sees directly and is usually required to be smooth and beautiful. The B side contains the hidden structure used to support the parts, and is usually rougher in finish than the A side. For molds with complex A-side and B-side designs, their manufacturing costs are usually higher. In addition, if the part design includes bottom cut features, additional sliding side action and core may be required, which will also increase the cost of the mold.

Production capacity

When parts are produced using the injection molding process, the cost of the individual part is usually reduced when the volume of production is very large, because the fixed costs (such as mold manufacturing and the rental/purchase of the injection molding machine) are spread more widely. However, for small batch projects, the cost of individual parts can be high because economies of scale cannot be fully exploited.

Part volume

The volume of the part determines the amount of plastic required and the cooling time, which affects energy consumption and production time. Larger parts require more plastic and longer cooling times, which can lead to higher material costs and longer production cycles.

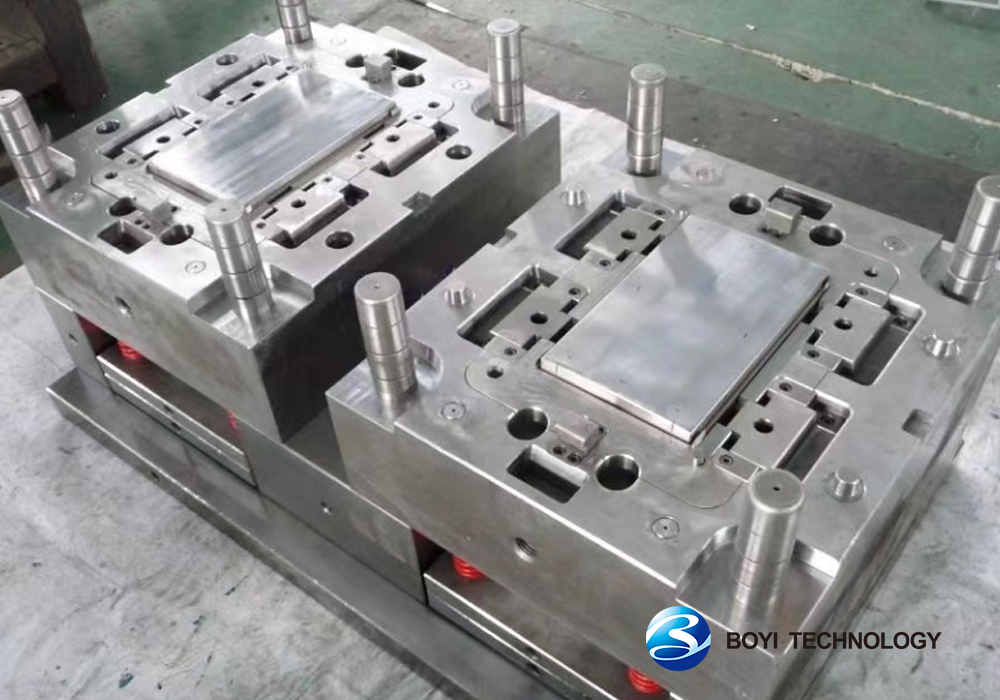

2.Mold tooling cost

The cost of molds depends on the complexity and size of the parts, which are two important factors. If the parts have complex geometric shapes or dense walls, it may be necessary to use more expensive special machines to manufacture molds, which can lead to an increase in mold costs. The specific breakdown of mold costs is as follows:

Material costs

The commonly used mold materials include steel, aluminum alloy, etc., and their prices are influenced by factors such as market supply and demand, production costs, etc. The price of steel is relatively high, but it has high hardness and wear resistance, making it suitable for manufacturing molds for long-term use. The price of aluminum alloy is relatively low, but its hardness is low and it is prone to wear and tear, making it suitable for manufacturing short-term or disposable molds.

Gating system

It can be divided into cold runner molds and hot runner molds. Cold runner molds may have injection residue in the runner, resulting in a certain amount of production waste. Hot runner is a method of heating to ensure that the plastic in the runner and gate remains in a molten state. After shutdown, it is generally not necessary to open the runner to remove the condensate. When restarting, only the runner needs to be heated to the desired temperature.

Mold structure

It can be divided into two plate molds and three plate molds. The two plate mold has a large water outlet, while the three plate mold has a small water outlet. Two plate mold opening is directly from the parting surface, and the product is ejected; Relatively speaking, the cost of mold manufacturing is low, but the cost of water outlet recycling is high. When the three board mold is opened, the product and the sprue will be separated, and each template will be separated by a certain distance. The adhesive part will fall from the distance between the two templates on the mold surface, while the cold sprue will fall from another space distance; Relatively speaking, the cost of mold manufacturing is high, but the product automatically separates and falls off, resulting in high efficiency.

Mold type

According to the shape and function of injection molds, mold types can be divided into the following:

Single cavity mold:The mold cost of a single cavity mold is relatively low, but because only one part can be produced per cycle, production efficiency is low, which may lead to higher production costs. This is particularly evident when mass production is required.

Multi cavity mold:A multi cavity mold has multiple cavities and can manufacture multiple parts simultaneously. The initial cost of multi cavity molds is usually higher due to the need for more steel and more complex designs. However, due to its high production efficiency, these costs can be quickly recovered. In long-term production, multi cavity molds can significantly reduce the cost of individual parts.

Injection Mold Tooling

4.Injection molding machine cost

Here are some common injection molding machine types and their impact on cost:

All-electric injection molding machine

This type of injection molding machine uses electricity instead of hydraulic oil and has the characteristics of high precision, high speed and high efficiency. All-electric injection molding machines are commonly used to produce high-quality, small and precision plastic parts. Although the initial purchase cost is high, its long-term operating costs are relatively low and it is more environmentally friendly.

Hydraulic injection molding machine

Hydraulic injection molding machines use hydraulic oil to drive injection and mold locking mechanisms, and are usually used to produce large, heavy or plastic parts with low precision requirements. The initial purchase cost of a hydraulic injection molding machine is low, but operating costs are high and there may be oil leakage and contamination issues. For example, the use of more expensive engineering plastics can increase manufacturing costs, while the use of less expensive ordinary plastic materials can reduce costs.

Vertical injection molding machine

The injection mechanism and the mold are fixed in the same vertical direction, which is suitable for the production of small, precise or complex plastic parts. Vertical injection molding machines usually have higher production efficiency and accuracy, but the initial purchase cost and operating costs are also higher. For example, large and heavy injection molding machines typically require a higher investment, but they are also more productive and can reduce the cost of individual parts.

Horizontal injection molding machine

The injection mechanism and mold of the horizontal injection molding machine are fixed in the horizontal and vertical directions respectively, which is suitable for the production of large, heavy or plastic parts with low precision requirements. In contrast, small injection molding machines may have a lower initial investment but a higher cost to produce individual parts.

5.Injection molding material cost

The amount of materials used in plastic injection molding directly affects production costs. Due to the different characteristics, applications, availability, and prices of injection molding raw materials, their costs also vary significantly.

| Material | Type | Unique Features | Common Applications | Price per Pound (USD) |

|---|---|---|---|---|

| ABS | Thermoplastic | Durable, lightweight | Electronics, keyboards, phone hardware, LEGO blocks, drainage systems, kitchenware | 1.30 |

| Polyethylene | Thermoplastic | Flexible, impact-resistant, water-resistant, moisture-resistant, recyclable | Food packaging, baby bottles, toys | 1.20 |

| Polypropylene | Thermoplastic | Water-resistant, flexible | Tupperware, children’s pools, toys, tableware, car batteries | 0.90 |

| Polystyrene | Thermoplastic | Warpage-resistant, shrinkage-resistant, impact-resistant | CD/DVD cases, packaging applications, household appliances | 1.00 |

| Polycarbonate | Thermoplastic | Impact-resistant, optically transparent, susceptible to chemicals | Auto headlights, bulletproof glass, eyeglasses, greenhouses, DVDs, cell phones | 2.30 |

| PVC (Polyvinyl Chloride) | Thermoplastic | Excellent electrical insulation, corrosion-resistant, fire-resistant | Electrical cables, pipes, windows, doors, building materials, clothing, toys etc. | 1.00 |

| PMMA (Poly(methyl methacrylate)) (Lucite) | Thermoplastic | High transparency, weather-resistant, UV and chemical resistant | Windows, light fixtures, billboards, vehicle windshields, airplane windows etc. | 2.50 |

| PTFE (Polytetrafluoroethylene) (Teflon) | Thermoplastic | Excellent heat resistance, chemical resistance, low friction coefficient | Nonstick coating for cookware, gasket material, piping systems, lining of chemical reactors etc. | 10.00 |

| PA (Polyamide) (Nylon) | Thermoplastic | High strength, wear resistance, heat and chemical resistance | Auto parts, machinery parts, electronic components etc. | 1.50 |

| PI (Polyimide) (Kapton) | Thermoplastic | High heat resistance, electrical insulation, chemical resistance and radiation resistance | High temperature electrical insulation materials, aerospace materials etc. | 5.00 |

Materials Guide

Comparing injection molding costs for different production volumes

Low-volume, medium volume, and high volume production are the three important stages in the injection molding process, each of which faces different challenges and cost factors. From the high cost of small batch production to the economies of scale of medium batch production, and then to the low cost and high efficiency of large batch production, enterprises need to respond flexibly and adopt effective strategies to reduce costs and improve production efficiency

| Production scale | Number of parts | Mold cost | Material cost per part | Total material cost | Labor cost per part | Total labor cost | Total injection molding cost | Cost per part (USD) |

|---|---|---|---|---|---|---|---|---|

| Low-Volume Manufacturing | 100 | $100 USD | $0.50 USD | $50 USD | $3 USD | $300 USD | $450 USD | $4.50 USD |

| Medium Volume production | 5,000 | $2,500 USD | $0.50 USD | $2,500 USD | $2 USD | $10,000 USD | $15,000 USD | $3.00 USD |

| High Volume Production | 100,000 | $25,000 USD | $0.50 USD | $50,000 USD | $1 USD | $100,000 USD | $175,000 USD | $1.75 USD |

How to save injection molding costs?

The strategy to save injection molding costs can be approached from multiple aspects, and the following are some suggestions:

Optimize product design: Reduce mold costs by simplifying design, reducing part count and optimizing mold structure. At the same time, consider using standardized parts and assemblies to reduce production and inventory costs.

Reasonable selection of materials: According to production needs, choose the right materials to avoid waste. At the same time, reasonable use of material properties, reduce unnecessary reinforcement materials.

Control the production process: Through accurate injection molding machine control and adjustment, reduce the overflow, lack of materials and defective products and other problems. At the same time, keep the mold and equipment in good condition, regular maintenance and maintenance.

Reduce energy costs: Optimize parameters such as temperature, pressure and time in the production process to reduce energy consumption. At the same time, consider the use of energy-saving technologies and equipment, such as high-efficiency injection molding machines, energy-saving cooling systems and LED lighting.

Increase production efficiency: Improve production efficiency through the introduction of automation and smart manufacturing technologies. For example, the use of robots, automated inspection equipment and intelligent controllers.

How to estimate the cost of injection molding?

The steps to estimate the cost of injection molding typically include the following:

Determine material cost: Calculate the cost of the required plastic raw materials based on the type, density and weight of the plastic required. This takes into account the purchase price of raw materials, transportation costs, processing costs and other related expenses.

Calculation of mold cost: According to the complexity of the mold, the size of the area, the thickness of the material and other factors, determine the design and manufacturing costs of the mold. Mold cost is an important part of injection molding cost, so sufficient attention should be paid to the estimation.

Analyze production process costs: This includes equipment costs, labor costs, energy costs, overhead costs, etc. Equipment costs include the purchase or lease of injection molding machines, maintenance and maintenance costs, etc.; Labor costs include the wages and benefits of operating workers; Energy costs include the cost of electricity, water and other required resources; Indirect costs include production management, quality control, equipment depreciation and other costs.

Calculation of other expenses: including the cost of packaging materials, transportation costs, taxes and other related expenses. These expenses may also have an impact on the total cost and should therefore be taken into account when estimating.

Injection molding cost calculator

The injection molding cost calculator can help you quickly estimate the cost of injection molding specific parts. By using an online injection molding cost estimator or consulting with an injection molding service provider, you can obtain benchmark prices and understand relevant cost factors.

The injection molding cost calculator usually provides the following options to help you calculate:

Step 1: You can choose the desired part type, size, and material, and then calculate the required cost.

Step 2: You can upload the 3D model to the calculator and obtain an estimated injection molding cost.

Step 3: You can choose the required services and then calculate the cost.

In addition, injection molding service providers typically use a cost comparison table to provide potential customers with a rough estimate of the process. This comparison table can help you understand the impact of different factors on injection molding costs, such as material type, part size, quantity, mold type, etc.

Obtain high-quality injection molding services at BoYi at the lowest price

Boyi Company provides a comprehensive injection molding service, from low-cost injection molding to mass production, to a variety of material options, to meet the needs of different customers. By choosing to work with Boyi, you have access to the professional services of a world-class team of engineers and the use of state-of-the-art equipment for manufacturing. This mode of cooperation ensures the high quality of parts and the efficiency of production.

For any injection molding project, no matter its complexity, Boyi Company is able to provide professional services. Whether it is a simple injection molding project or a project overmolding or insert molding, Boyi has the appropriate solutions and experience.

If you are looking for professional injection molding services, partnering with Boyi is a wise choice. Contact Boyi today to get the right injection molding quote for your project, so that your project can get the most professional support and help.

Conclusion

In summary, understanding injection molding costs and estimation methods is of great significance for controlling production costs, improving production efficiency, and product quality. Enterprises can choose appropriate estimation methods and tools based on actual situations to obtain accurate injection molding cost estimation results, and based on this, develop effective cost control measures.

FAQ

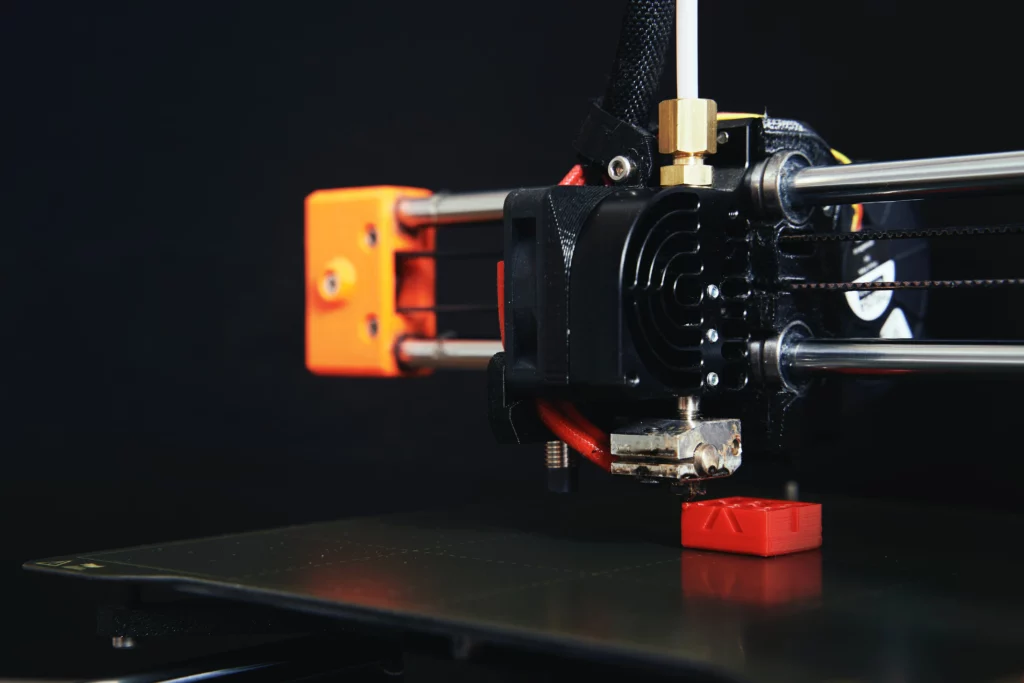

When considering alternatives to injection molding, there are several options to consider. First, 3D printing can quickly and accurately produce complex shaped parts, which is an economical and convenient alternative to injection molding. Secondly, hot pressing and compression molding are also alternatives to be considered, and these two processes have certain advantages in terms of material cost and production efficiency

Not all plastics can be injection molded. Injection molding requires a certain fluidity and processability of the plastic to fill the mold and form the desired shape. However, some plastics may not be suitable for injection molding due to their special properties or processing requirements, such as the melting point of the plastic is too high or too low, or sensitive to heat and pressure. Therefore, when selecting injection molding as a manufacturing method, it is necessary to evaluate the suitability of plastics and select suitable plastic materials for injection molding.

Hourly rate for injection molding can vary depending on several factors such as the size and complexity of the mold, the type of machine used, the materials being molded, and the experience and expertise of the injection molder. In general, however, the hourly rate for injection molding can range from a few hundred dollars to several thousand dollars per hour, depending on the specific circumstances. It’s important to note that this rate is not a fixed cost and can be affected by various factors such as machine maintenance, operator efficiency, and production volume. Therefore, it’s essential to work with a qualified injection molder who can provide a detailed quote based on your specific requirements and project parameters.