In the realm of CNC machining, where precision and efficiency reign supreme, up milling and down milling are two techniques used in CNC (Computer Numerical Control) machining, especially in milling operations. These techniques refer to the direction of the cutting tool’s rotation in relation to the direction of the workpiece feed.

In this exploration, we delve into the fundamental differences between up milling and down milling, examining their respective advantages, limitations, and applications. You can also find out more about our cnc tips.

What is Up Milling?

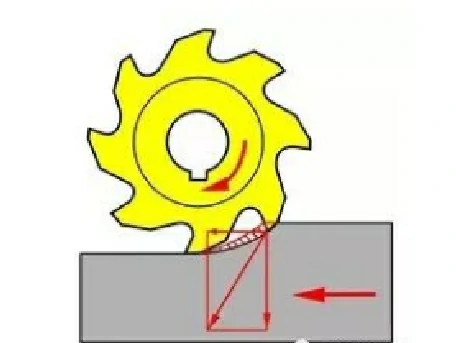

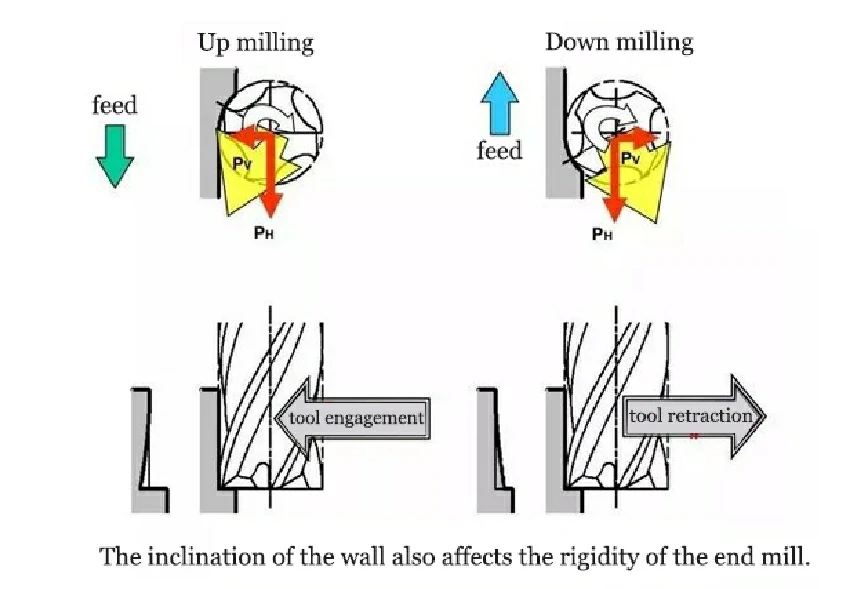

Up milling: refers to the cutting speed direction of the tool being opposite to the direction of workpiece movement.

Up milling, also known as conventional milling, in up milling, the thickness of the chips starts at zero and gradually increases until the end of the cut. The milling process includes a polishing effect. The cutting forces tend to lift the workpiece (there is a tendency to raise the workpiece).

Up milling is suitable for machining brittle materials and when cutting forces need to be minimized. However, it may not be as efficient as down milling in certain applications, especially when dealing with ductile materials or when higher material removal rates are required.

Up milling is characterized by the following features:

- Chip Formation: Up milling produces thick chips that start small and increase in size as the cutter advances through the material. These chips are often ejected away from the cutter and workpiece, reducing the likelihood of re-cutting and minimizing heat buildup.

- Tool Life: Since the cutter engages with the material gradually, up milling tends to prolong tool life. The cutting forces are distributed more evenly, resulting in reduced wear on the cutting edges.

- Workpiece Fixturing: Up milling is less demanding in terms of workpiece fixturing because the cutting forces tend to lift the workpiece onto the fixture, enhancing stability.

- Surface Finish: While up milling generally produces a satisfactory surface finish, it may exhibit minor irregularities due to the nature of chip formation.

However, up milling also has its drawbacks:

- Workpiece Fixturing: It requires sturdy workpiece fixturing to prevent the workpiece from lifting off the table due to cutting forces. This can be challenging for thin or flexible materials.

- Initial Impact: The initial impact of the cutter against the workpiece can cause more significant forces, potentially leading to workpiece deflection or tool breakage if not properly controlled.

What is Down Milling?

Down milling: refers to the cutting speed direction of the tool being the same as the direction of workpiece movement.

Down milling, also known as climb milling, in down milling, the thickness of the chips is at its maximum at the beginning, decreasing as the cut progresses, resulting in reduced chip deformation. The cutting forces are directed towards the workpiece.

For achieving good surface quality, we typically use down milling. Down milling is suitable for machining ductile materials and when high material removal rates are required. It can also be utilized for harder metals like titanium, vanadium titanium alloys, and metal ceramics. Throughout the machining process, it can execute various cutting forms including grooves, holes, boring, helical milling, recesses, and chamfers.

Down milling is characterized by the following attributes:

- Chip Formation: Down milling generates thin chips that start thick and decrease in size as the cutter progresses. These chips tend to stay in contact with the workpiece and cutter, increasing the likelihood of re-cutting and elevating temperatures at the cutting interface.

- Tool Life: Due to the sudden engagement of the cutter with the material, down milling typically results in shorter tool life compared to up milling. The cutting edges experience higher stress concentrations, leading to accelerated wear.

- Workpiece Fixturing: Down milling requires more rigid workpiece fixturing to counteract the tendency of the cutting forces to push the workpiece away from the fixture. Adequate clamping is essential to prevent chatter and maintain dimensional accuracy.

- Surface Finish: Down milling often yields a superior surface finish compared to up milling. The reduced thickness of the chips and the absence of irregularities contribute to smoother surface textures.

Despite its advantages, down milling also has some drawbacks:

- Increased Tool Wear: Down milling tends to cause more tool wear due to the cutting forces pushing the tool against the workpiece, leading to higher friction and heat generation.

- Heat Build-up: The increased friction in down milling can result in higher temperatures, which may affect tool life and surface finish, especially when machining heat-sensitive materials.

- Higher Power Consumption: Due to the higher cutting forces involved, down milling generally requires more power compared to up milling, making it less energy-efficient.

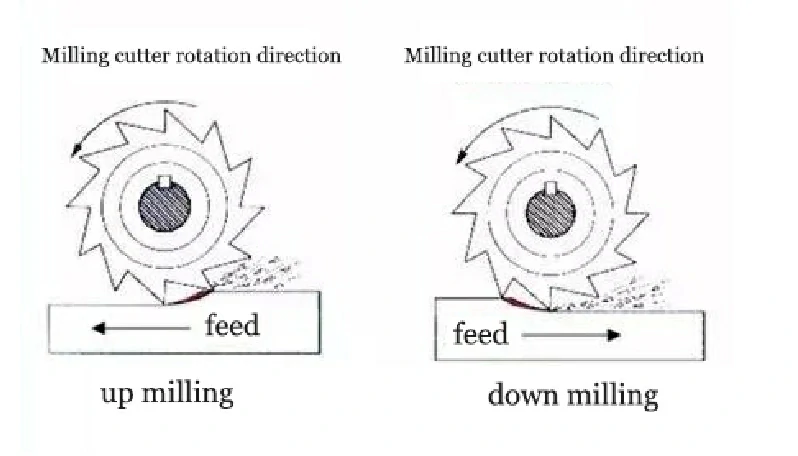

Up Milling and Down Milling Difference

Here’s a breakdown of their differences:

Difference 1: Cutting Method

The cutting method refers to the relative motion between the cutting tool and the workpiece during the machining process.

In up milling, the rotation direction of the cutting tool is opposite to the feed direction of the workpiece, resulting in cutting forces directed upwards and the chips gradually increasing from thin to thick. Conversely, in down milling, the rotation direction of the cutting tool aligns with the feed direction of the workpiece, causing cutting forces to be directed downwards and the chips decreasing gradually from thick to thin. These two cutting methods exhibit differences in cutting forces, surface quality, chip morphology, and tool wear, so the choice between them should consider factors such as material properties, surface roughness requirements, and machine tool performance.

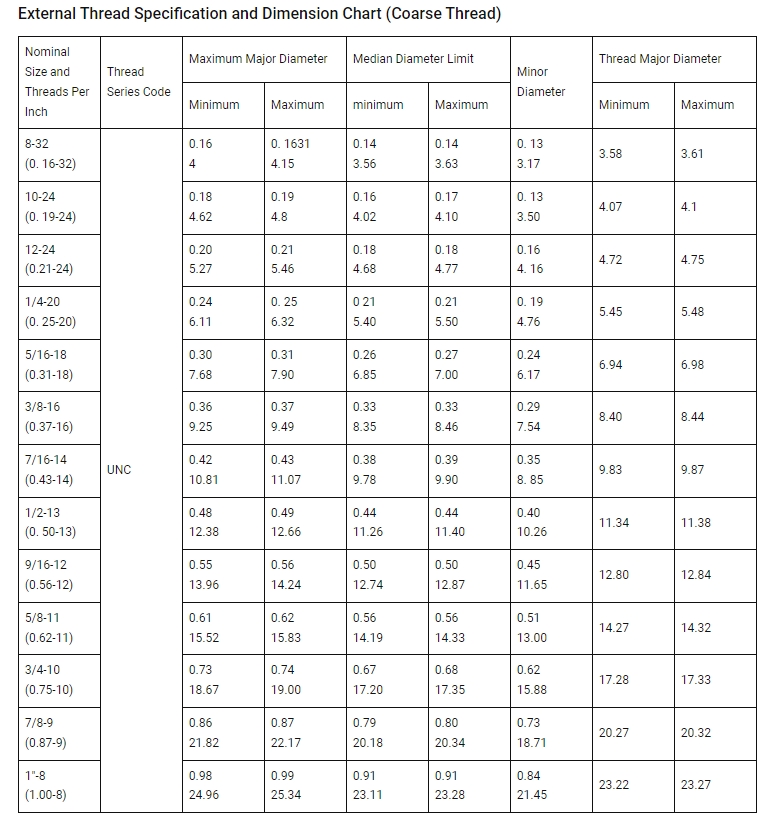

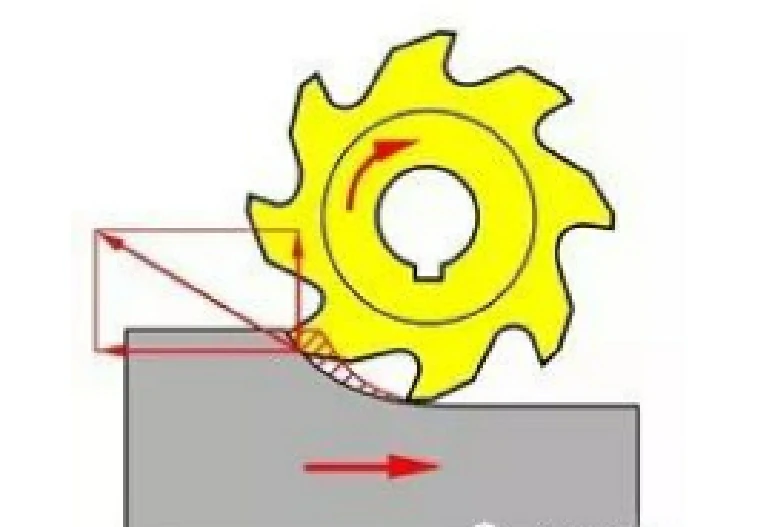

Table 1: Comparison of up milling and down milling cutting methods

| Movement of the cutting tool and workpiece | During side milling | During slot milling | |

| Up milling |  |  |  |

| Down milling |  |  |

Table 2: General performance comparison of up milling and down milling

| Down milling | Up milling | |

| Tool life | Long | Short |

| Surface roughness of the machined surface | Slightly poor | Relatively good |

| Machining precision (inclination) | Undercut | Overcut |

| Vibration damping effect | vibration-resistant | Prone to vibration |

| Chip evacuation | PSlightly poor | Relatively good |

Difference 1: Cutting Accuracy

The following are some differences in cutting accuracy between up milling and down milling:

Surface quality: up milling typically achieves higher surface quality because the cutting process is more stable, reducing the likelihood of vibration and workpiece lifting. This helps to reduce surface roughness and improve the surface finish of the workpiece.

Dimensional accuracy: In up milling, the direction of cutting forces helps to keep the workpiece stable, thus usually achieving better dimensional accuracy. In contrast, down milling may be affected by cutting forces causing workpiece lifting, which can result in larger dimensional deviations.

Cutting process stability: The cutting process in up milling is relatively stable, with chip evacuation being smoother, thereby reducing vibration and instability factors during machining, and enhancing machining precision.

Machining efficiency: Although up milling typically achieves higher precision, the cutting speed may be limited due to lower cutting forces, affecting machining efficiency. On the other hand, down milling, with its higher cutting forces, may be more suitable for applications requiring higher machining speeds.

Table 3: Machining accuracy of up milling and down milling

| The style of vertical milling cutte | Side cutting | Milling groove | ||||

|  | |||||

| Types | Number of flutes | Helix angle | Feed | Feed | ||

| 0.11mm/rev | 0.11mm/rev | |||||

| Way | Way | |||||

| Up milling | Down milling | Up milling | Down milling | |||

| SSM2080 | Two inserts | 30° |  |  |  | |

Conclusion: Chart of Difference Between Up Milling and Down Milling

In summary, while up milling and down milling achieve similar results in terms of material removal, they differ in terms of cutting forces, surface finish, and tool wear. The choice between them depends on factors such as the material being machined, the rigidity of the setup, desired surface finish, and the type of CNC machine being used.BOYI provides a chart to summarize and facilitate everyone’s decision-making.

Table 4: up milling and down milling Chart

| Up Milling | Down Milling |

|---|---|

| The direction of rotation of the milling cutter is opposite to the direction of the workpiece | The direction of rotation of the milling cutter is consistent with the feed direction of the workpiece |

| Up milling requires greater cutting force | The cutting force required for down milling is smaller than that required for up milling |

| The cutting thickness of the milling cutter is the maximum when zero is cut out | The cutting thickness is the largest when the cutter cuts in and the smallest when cutting out |

| The milling cutter has a tendency to pull the workpiece away from the table | The milling cutter gives the workpiece a force that pushes the workpiece towards the table |

| Special clamps are needed to hold the workpiece in place | The milling cutter will press the workpiece towards the table, so no special tooling is required to hold the workpiece |

| The chip remains in front of the cutter during cutting | Chips are left behind the cutter during cutting |

| Difficulty in cutting | Chip handling is easy |

| The cutting process does not produce a force to pull the workpiece towards the tool | There is a force that pulls the workpiece towards the tool during cutting |

| After the tool has a distance of slip on the machined surface, it can really cut in, and the surface roughness is poor | Compared with the up milling, the surface roughness is good |

| In up milling, the horizontal milling force borne by the workpiece is opposite to the direction of the feed speed, and the lead screw of the milling machine table is always in contact with the nut | When down milling, the horizontal milling force borne by the workpiece is the same as the feed speed. Because there is a gap between the screw nut, the milling cutter will drive the workpiece and the workbench to move, so that the milling feed is not uniform and it is easy to hit the knife |

| The up milling is generally only used for roughing and removing black skin | Down milling is suitable for finishing |

| Shorter life than down milling tool | Long tool life |

BoYi is Your Preferred Partner for CNC Milling Services

BoYi stands as an ideal partner for CNC milling services, delivering precision, efficiency, and reliability. With state-of-the-art equipment and a skilled team, BoYi ensures superior quality and accuracy in every project. Whether it’s rapid prototyping or high-volume production, BoYi commitment to excellence makes them a preferred choice for meeting diverse machining needs.

Put your parts into production today

All uploads are secure and confidential.

FAQ

It offers better chip evacuation, reduced cutting forces directed into the workpiece, potentially longer tool life, and smoother surface finish. These benefits contribute to improved machining efficiency and higher-quality finished parts.

Down milling is often considered better due to its advantages like improved chip evacuation, reduced cutting forces, potentially longer tool life, and smoother surface finish. However, the choice between up milling and down milling depends on factors like material, machine setup, and desired outcome.

Up milling (climb milling) offers reduced workpiece deflection and lower cutting temperatures but suffers from poor chip evacuation and higher cutting forces at the start. Down milling (conventional milling) provides better chip evacuation and lower cutting forces but may cause workpiece lift and higher cutting temperatures. The choice between the two depends on factors like material properties and machining requirements.