The surface finish symbol provides a standardized way in engineering and manufacturing to convey the required surface texture of parts or products. In this article, we will delve into everything you need to know about surface finish symbols, including their meanings, usage, and importance in various industries.

What are symbols of surface finish?

Surface finish symbols are graphical representations used on technical drawings to specify the texture of a surface. They consist of a symbol or series of symbols placed adjacent to the surface feature they describe.

These symbols are standardized by various organizations, such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), to ensure consistency and clarity in engineering drawings worldwide.

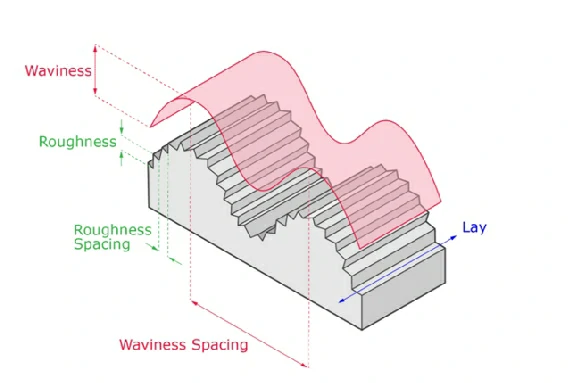

The three elements that make up surface finish: roughness, waviness, lay

1.Roughness:

- Roughness refers to the small-scale deviations from the ideal surface profile of a component. These deviations typically occur due to the machining process used to manufacture the part or other factors such as wear and corrosion.

- Roughness is quantified by parameters such as Ra (arithmetical mean roughness), Rz (maximum height of the roughness profile), Rt (total height of the roughness profile), and others.

- Ra, in particular, is a widely used parameter representing the average deviation of the surface heights from the mean line within a specified sampling length.

2.Waviness:

- Waviness refers to the larger-scale deviations from the ideal surface profile that occur over longer wavelengths compared to roughness. These deviations may result from factors such as tool chatter, machine vibrations, or inherent material properties.

- Unlike roughness, which represents small irregularities, waviness encompasses more significant undulations or patterns on the surface.

- Waviness is characterized by parameters such as Wt (total waviness height) and Wc (waviness cycle wavelength), which quantify the amplitude and frequency of the waves, respectively.

- While roughness affects the functional characteristics and performance of a part at a microscopic level, waviness can influence its macroscopic properties and appearance.

3.Lay:

- Lay refers to the direction or orientation of the predominant surface pattern or texture resulting from the machining process. It represents the alignment of tool marks, grain structure, or other surface features relative to a reference direction.

- The lay of a surface can significantly impact its functional properties, such as friction, wear resistance, and paint adhesion.

- Commonly used lay symbols include arrows or lines indicating the direction of predominant surface texture, such as longitudinal, transverse, or isotropic.

Common surface finish symbols and their meaning

Here are some common surface finish symbols along with their meanings:

Table 1: Surface finish symbols and their meanings

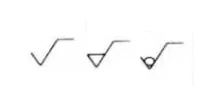

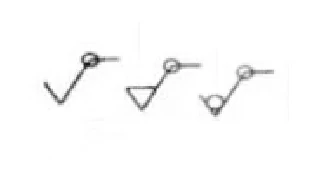

| Symbol | Meaning and explanation |

| Basic symbol, indicating that the surface can be obtained by any method, when no roughness parameter values or related descriptions (e.g., surface finishing, local heat treatment status, etc.) are added, only for simplified code marking |

| The basic symbol plus a dash indicates that the surface was obtained by removing the material. For example: turning, milling, drilling, grinding, cutting, cutting, polishing, corrosion, EDM, gas cutting, etc |

| The basic symbol plus a small circle indicates that the surface was obtained without removing the material. For example: casting, forging, stamping deformation, hot rolling, cold rolling, powder metallurgy and so on. Or a surface used to maintain the original supply condition (including maintaining the condition of the previous process) |

| A horizontal line can be added to the long edge of the above three symbols to mark the relevant parameters and descriptions |

| A small circle can be added to each of the above three symbols to indicate that all surfaces have the same surface finish requirements |

Table 2: Labeling of surface finish height parameters

| Ra | Rz, Ry | ||

| Symbol | Significance | Symbol | Significance |

| The upper limit of Ra for surface finish obtained by any method is 3.2μm |  | The upper limit of Ry for surface finish obtained by any method is 3.2μm |

| The upper limit of Ra for surface finish obtained by material removal is 3.2μm |  | The upper limit of Rz for surface finish obtained without material removal is 200μm |

| The upper limit of Ra for surface finish obtained without material removal is 3.2μm |  | The surface finish obtained by material removal has an upper limit of 3.2μm and a lower limit of 1.6μm for Rz |

| The upper limit of Ra and lower limit of Ra for surface finish obtained by material removal are 3.2μm and 1.6μm respectively |  | The upper limit of the surface finish obtained by the material removal method is 3.2μm for Ra and 12.5μm for Rz |

| The maximum surface finish of Ra obtained by any method is 3.2μm |  | The surface finish obtained by any method has a maximum Ry of 3.2μm |

| The maximum surface finish of Ra obtained by material removal is 3.2μm |  | Surface finish obtained without material removal has a maximum Ry of 200μm |

| For surface finish obtained without material removal, the maximum value of Ra is 3.2μm |  | The maximum and minimum Rz values of surface finish obtained by material removal are 3.2μm and 1.6μm |

| The maximum value of Ra and the minimum value of Ra were 3.2μm and 1.6μm respectively for the surface finish obtained by material removal |  | The surface finish obtained by material removal method has a maximum of 3.2μm for Ra and 12.5μm for Ry |

Note: When less than 16% of all the measured values of the surface finish parameter are allowed to exceed the specified value, the upper or lower limit value of the surface finish parameter should be marked on the drawing.

Affecting factors for surface finish

Surface finish, the quality of a surface texture, is influenced by various factors spanning material properties, machining processes, tooling, and environmental conditions. Here are some of the key factors that impact surface finish:

1.Material Properties

The type of material being used plays a significant role in determining surface finish. Different materials have unique properties such as hardness, ductility, and texture, which affect how they respond to manufacturing processes.

2.Manufacturing Process

The method used to create the product or part greatly impacts its surface finish. Processes like machining, grinding, polishing, casting, forging, and extrusion all have different effects on surface texture and quality.

3.Cutting Tools and Equipment

The quality and condition of cutting tools and equipment used in manufacturing processes can affect surface finish. Sharp tools with appropriate geometries can produce smoother surfaces, while dull or improper tools may result in rougher finishes.

4.Cutting Parameters

Parameters such as cutting speed, feed rate, depth of cut, and tool geometry can significantly influence surface finish. Optimizing these parameters for specific materials and processes is essential for achieving desired surface quality.

5.Workpiece Stability

The stability of the workpiece during machining or other manufacturing operations is critical for achieving consistent surface finish. Vibrations or movement can lead to irregularities in the surface texture.

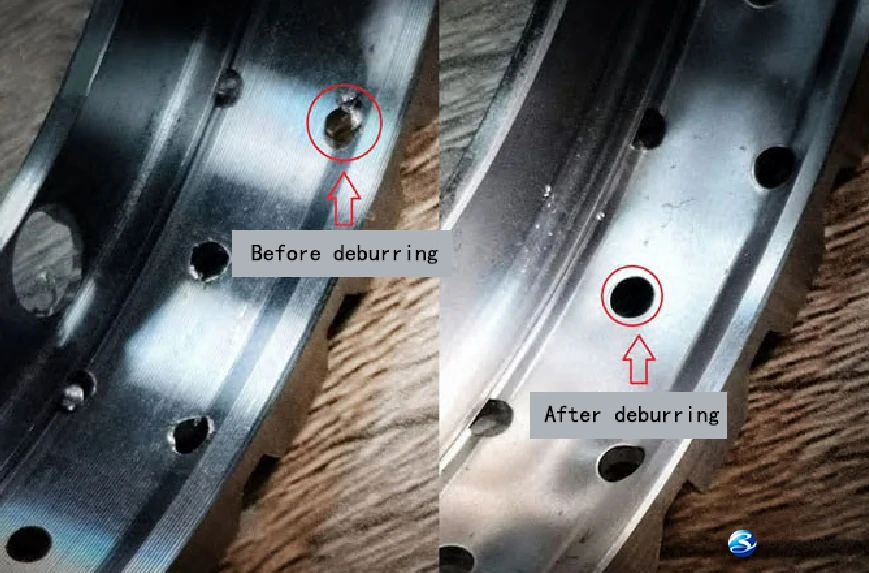

6.Surface Preparation

Pre-treatment of the workpiece, such as cleaning, deburring, and pre-finishing, can affect the final surface quality. Proper surface preparation ensures that the material is free from contaminants and defects before undergoing finishing processes.

How to measure surface finish

Several methods are commonly used to measure surface finish:

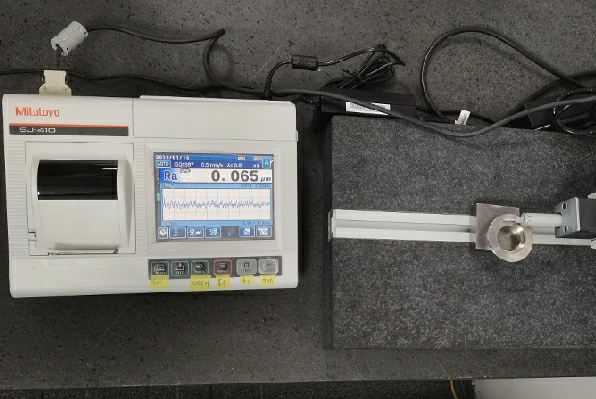

- Contact Profilometers: These instruments use a stylus or probe to physically trace the surface, measuring variations in height. The result is typically given in Ra (average roughness), Rz (maximum height of the profile), or Rt (total height of the profile).

- Non-Contact Profilometers: Laser or optical profilometers measure surface finish without touching the surface, providing fast and accurate results. They are suitable for delicate or sensitive materials.

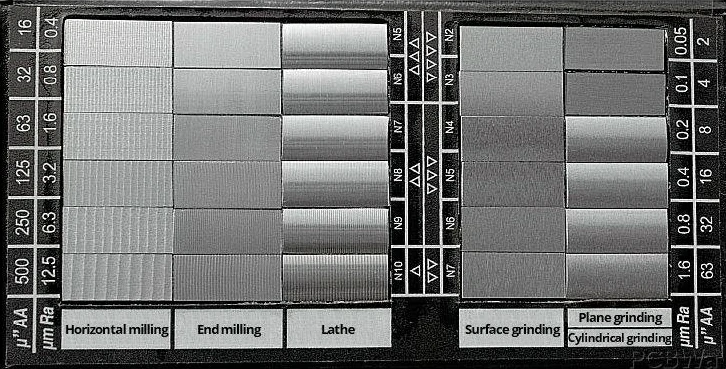

- Surface Roughness Comparators: These visual aids consist of a set of sample surfaces with varying roughness levels. Operators compare the surface of a workpiece against these standards to determine roughness visually.

- Atomic Force Microscopy (AFM): AFM provides extremely high-resolution imaging of surface features at the nanoscale level, making it suitable for research and development applications.

Inspecting Surface Finish

Inspecting surface finish involves evaluating the measured data against specified requirements or standards. Key considerations include:

- Specification Compliance: Verify whether the measured surface finish meets the specified requirements outlined in engineering drawings or industry standards.

- Defect Detection: Surface inspection may involve identifying defects such as scratches, pits, cracks, or irregularities that affect surface quality.

- Statistical Analysis: Analyze surface finish data statistically to ensure consistency and identify trends over time. Process capability indices such as Cp and Cpk can help assess manufacturing process performance.

- Visual Inspection: In addition to numerical measurements, visual inspection is often performed to assess surface finish quality, especially for aesthetic or cosmetic requirements.

Standards and Specifications

Several international standards and specifications govern surface finish measurement and inspection, including:

- ISO 25178: Geometrical product specifications (GPS) – Surface texture: A comprehensive standard covering parameters, filtration, and evaluation procedures for surface texture measurement.

- ANSI/ASME B46.1: Surface Texture (Surface Roughness, Waviness, and Lay): This standard provides guidelines for specifying and measuring surface texture parameters.

- ASTM E1444: Standard Practice for Magnetic Particle Testing: While not specific to surface finish measurement, this standard outlines procedures for detecting surface and near-surface flaws using magnetic particles.

Applications of surface finish

- Aerospace: Critical components like turbine blades and engine parts require precise surface finishes to ensure optimal performance and durability.

- Automotive: Engine blocks, cylinder heads, and transmission components demand specific surface finishes for functionality and longevity.

- Medical devices: Implants, prosthetics, and surgical instruments necessitate smooth surface finishes to minimize friction and prevent bacterial adhesion.

- Consumer electronics: Enclosures, connectors, and internal components require aesthetically pleasing surface finishes for consumer appeal and durability.

Conclusion

Understanding these symbols is essential for ensuring that manufactured components meet performance, functionality, and regulatory requirements. By leveraging appropriate measurement techniques and considering factors influencing surface finish, manufacturers can achieve consistent and precise surface textures in their products, thereby enhancing functionality, aesthetics, and overall quality

Boyi provides customers with high-quality surface finishing services at the most favorable prices. From anodizing, electroplating, sandblasting to polishing, we offer a variety of surface treatment options to meet the diverse needs of our customers.

Put your parts into production today

All uploads are secure and confidential.

FAQ

The purpose of the surface finish symbol, often seen on engineering drawings, is to specify the desired surface texture or roughness for a particular part or component. This symbol provides important information to manufacturers and machinists about the required quality of the surface finish, which can affect the part’s functionality, appearance, and compatibility with other components.

Surface finish can be identified through visual inspection, tactile examination, or by using instruments like profilometers that measure roughness quantitatively. These methods ensure the surface meets desired specifications for quality and functionality.

Surface finishes typically come in several types, including but not limited to machining, grinding, polishing, and sandblasting. Each type has distinct characteristics and suitability for various applications. Choosing the appropriate surface treatment method is crucial based on design requirements and manufacturing processes.