Metal Injection Molding (MIM) is a new powder metallurgy near net forming technology that has emerged from the plastic injection molding industry. It is well known that plastic injection molding technology produces various complex shaped products at a low price, but plastic products have low strength. To improve their performance, metal or ceramic powder can be added to plastics to obtain products with high strength and good wear resistance.

In recent years, this idea has evolved to maximize the content of solid particles and completely remove the binder and densify the formed billet during subsequent sintering processes. This new powder metallurgy forming method is called metal injection molding.

What is metal injection molding?

Metal injection molding, also known as composite forming technology, is a processing technique that involves injecting metal materials into specific molds under liquid or gas pressure. The process includes a series of steps such as heating, cooling, and forming, ultimately producing various specialized parts and components according to the design drawings of the molds.

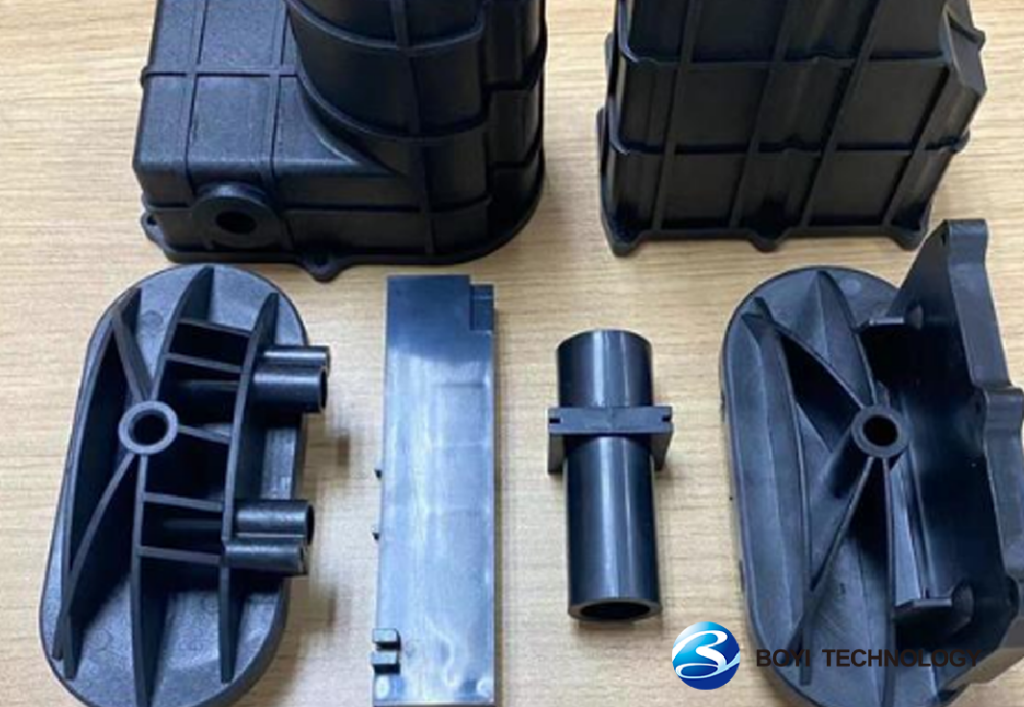

Furthermore, metal injection molding can also refer to the mixing of fine metal powder with a binder material to create a “feedstock,” which is then solidified using injection molding. This molding process can create large-volume, complex parts. After molding, the components undergo adjustments to remove the binder and densify the powder. The finished small parts can be applied in various industries.

Why use metal injection molding?

The attractiveness of metal injection molding lies in its excellent performance in producing small and complex metal components. It allows for the manufacture of highly precise and complex components, whose shape and details are difficult to achieve through traditional metal processing methods. This technology can produce parts with approximate final shapes by injecting a mixture of metal powder and adhesive, followed by injection molding, degreasing, and sintering, thereby reducing subsequent processing steps.

Secondly, metal injection molding provides a high degree of design flexibility, allowing engineers to achieve complex geometric shapes and micro structures without sacrificing material performance. And it can also improve production efficiency, reduce subsequent processing and cutting processes, and reduce waste generation. This has significant advantages in saving resources, improving production efficiency, and reducing manufacturing costs.

Metal injection molding process

The MIM manufacturing process generally includes: mixing granulation, injection molding, degreasing, sintering, and secondary treatment. The equipment involved includes a mixing and granulation integrated machine, MIM specialized injection molding machine, degreasing furnace, sintering furnace, and various detection and secondary processing equipment.

1.Preparation of metal powder

Metal powder injection molding has high requirements for raw material powder, including powder morphology, particle size, particle size composition, specific surface area, loose density, etc.

There are two main methods for raw material powder used in metal powder injection molding: hydroxyl method and atomization method. Metal powder injection molding requires very fine raw material powder, so the requirements for metal powder injection molding are very high.

2.Binder

Adhesives are the core of metal injection molding (MIM) technology. In MIM, adhesives have two basic functions: enhancing flowability to fit injection molding and maintaining the shape of the billet. In addition, they should also have characteristics such as easy removal, no pollution, non toxicity, and reasonable cost. As a result, various types of adhesives have emerged, and in recent years, they are gradually shifting from selecting based solely on experience to meeting the requirements of degreasing methods and binder functions, The development direction of designing adhesive systems with targeted approaches.

The requirements for binder in metal powder injection molding include: small contact angle with the powder and strong adhesion; No two-phase separation occurs with the powder; After cooling, it should have a certain strength; When degreasing, it will not cause serious defects such as cracking and bubbling of the green body; The viscosity of pure binder at injection temperature should be less than 0.1Pa · s.

3.Mixing

Mixing is the process of mixing metal powder with a binder to obtain a uniform feed. The process of mixing and effectively stirring the raw material powder and binder to homogenize and meet the injection requirements. The nature of the feed determines the performance of the final product. This process step has currently remained at the level of experience exploration, and an important indicator for evaluating the quality of the mixing process is the uniformity and consistency of the obtained feed.

So, the mixing process has become very important, which will involve various factors such as the way and sequence of adding binders and powders, the mixing temperature, the characteristics of the mixing device, etc. Ultimately, an important indicator for evaluating the quality of the mixing process is the uniformity and consistency of the feed obtained.

The commonly used mixing devices for metal injection molding (MIM) include double screw extruders, Z-shaped impeller mixers, single screw extruders, plunger extruders, double planetary mixers, double cam mixers, etc. These mixing devices are all suitable for preparing mixtures with viscosity within the range of 1-1000Pa · s.

4.Injection molding

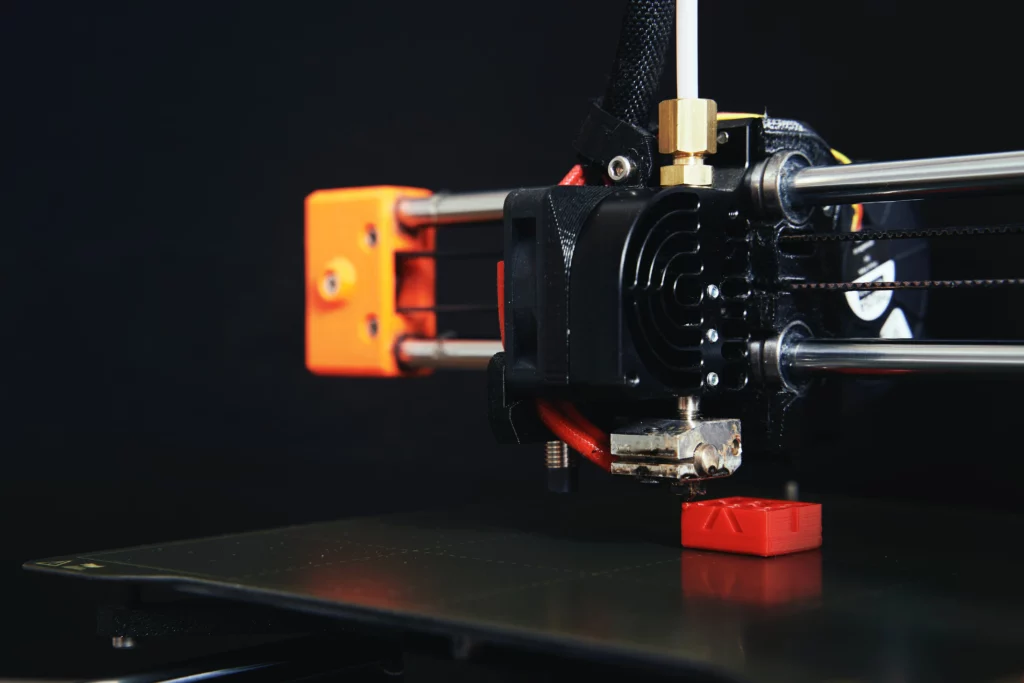

In the powder injection molding process, injection molding is an important process that determines the production of qualified green billets. The mixture is heated by screw stirring in the injection molding machine, and the plasticized mixture is injected into the mold cavity through the injection molding machine feeding system, and maintained under pressure to compensate for cooling shrinkage.

After cooling and solidification, when the part has sufficient strength, open the mold and use a ejector pin to push the part out to obtain a green body.

5.Defatting

The green body is manually and regularly placed on the ceramic plate, and then waiting to enter the degreasing furnace for degreasing.

From the degreasing steps, all degreasing methods can be roughly divided into two categories: one is the two-step degreasing method. The two-step degreasing method includes solvent degreasing+thermal degreasing, siphon degreasing – thermal degreasing, etc. The one-step degreasing method is mainly the one-step thermal degreasing method, and currently the most advanced is the amaetamold method.

6.Sintering

Sintering is an important process in powder metallurgy and also the final step in the metal powder injection molding process.

By sintering, metal powder injection molded products can achieve full density or near full densification. In the sintering stage, it is necessary to control the change in sintering temperature to obtain high-density metal parts, avoid any surface cracks, and maintain the original shape of the parts with the same size shrinkage rate.

7.Secondary treatment

After sintering, sintered parts usually have certain burrs. The main part of the burrs can be removed by laser first, and then the remaining part can be removed by sandblasting, etc.

Sandblasting is a technique that uses the impact of high-speed sand flow to clean burrs and roughen surfaces. Sandblasting generally includes copper ore, quartz sand, diamond sand, iron sand, Hainan sand, etc. Sandblasting can not only achieve a matte effect on the surface of the product, but also deburring.

What are the advantages of injection molding?

Metal Injection Molding (MIM) has multiple advantages, and the following are some of the main benefits:

1.Complexity

Metal injection molding (MIM) has almost no limitations in shape design, making it an ideal choice for combining various independent parts into highly complex and multifunctional products. The design rules are similar to injection molding, which means that almost all types of products can benefit from this advanced process.

2.Precision

Metal injection molding can achieve high precision. The variation in size is usually within the range of ± 0.1, and some characteristics can even reach ± 0.005. This high level of precision makes metal injection molding the preferred process for pursuing high-quality and precision components.

3.Weight and dimensions

Metal injection molding performs particularly well in handling small components, especially for components weighing less than 80 grams, with the lowest range being below 40 grams. Metal injection molding reduces the weight of components by adopting new technologies, thereby minimizing raw material costs to the greatest extent possible.

4.Thinning

For components with a wall thickness less than 5 millimeters, metal injection molding is the most suitable choice. Of course, thicker outer walls can also be treated, although it may lead to increased processing time and additional material costs.

5.Production capacity

Metal injection molding is suitable for products with annual demand ranging from thousands to millions, achieving economical and efficient production. However, for small batch products, customers may need to invest in molds and tools, which may have a certain impact on costs.

6.Multiple material selection

Metal injection molding, as a multifunctional process, can handle various metal materials, including ferroalloys, superalloys, titanium alloys, copper alloys, etc. Although non-ferrous alloys such as aluminum and copper are also technically feasible, other more economical processing methods such as die casting or CNC machining are usually chosen.

Materials Guide

What are the disadvantages of injection molding?

The disadvantages of metal injection molding mainly include the following points:

1.High cost

The metal injection molding cost is high because it requires higher equipment and mold costs, as well as higher raw material costs, resulting in relatively high production costs.

Understand Injection Molding Cost and How to Estimate It

2.High process difficulty

Metal injection molding requires precise control of process parameters such as temperature, pressure, and time, otherwise it is prone to problems such as insufficient filling, overflow, and warping, requiring high process requirements.

3.Limited application scope

Metal injection molding is suitable for the production of small and complex shaped metal parts. For large or simple metal parts, traditional metal processing methods may be more suitable.

4.The utilization rate of metal powder is not high

Due to the poor fluidity of metal powder, it is easy to encounter uneven filling and waste of metal powder during the metal injection molding process.

Application of metal injection molding

Metal injection molding is suitable for applications that require high precision, shape, and material properties, such as:

Automotive manufacturing industry: Metal injection molding can be used to produce automotive engine parts, transmission parts, intake manifolds, etc. These parts need to have high precision, high strength, and high temperature resistance.

Medical device industry: Metal injection molding can be used to produce precision parts in medical devices, such as dental implants, surgical instruments, etc. These parts need to have high precision, non-toxic and sterile characteristics.

Aerospace field: Metal injection molding can be used to produce aircraft components, rocket engine parts, etc. These parts need to have high strength, high precision, and lightweight characteristics.

Electronic products industry: Metal injection molding can be used to produce precision parts in electronic products such as mobile phones, tablets, etc., such as camera brackets, antennas, etc. These parts need to have high precision and lightweight characteristics.

What is the difference between metal injection molding and plastic injection molding?

Metal injection molding and plastic injection molding are two different processes, and the main difference between them lies in the materials and process used.

Material selection: Metal injection molding mainly uses metal powder or metal alloys, such as aluminum alloy, magnesium alloy, zinc alloy, copper alloy, etc., and is processed through injection molding at high temperature and high pressure. Plastic injection molding mainly uses various plastic materials, such as ABS, PC, POM, PVC, etc.

Injection molding process: Metal injection molding usually uses die-casting technology, which requires higher injection pressure and longer injection time. Plastic injection molding, on the other hand, adopts a compression molding process, which requires shorter process time and lower process pressure.

Product application: Parts manufactured by metal injection molding process have the characteristics of high density, high precision, and high strength, which are suitable for producing complex shaped parts, especially some parts that are difficult to process through mechanical processing and other process methods. Plastic injection molding has a wider range of applications and can be used to produce parts of various shapes and sizes.

Conclusion

Overall, metal injection molding technology has become one of the highly favored advanced manufacturing technologies in today’s manufacturing industry due to its flexibility, high precision, economy, and suitability for various metal materials. By fully utilizing this process, manufacturers can achieve more complex, precise, and economical production of metal components, driving continuous innovation and development in product design and manufacturing.

FAQ

Yes, Injection molding is a manufacturing process primarily used for producing plastic parts, and it involves injecting molten plastic material into a mold cavity. While this process is not commonly used for metals, there is a similar process called metal injection molding (MIM) that allows for the production of small, complex metal parts.

Various metals and alloys can be used in metal injection molding (MIM), depending on the specific requirements of the application. Common metals include stainless steels, tool steels, low-alloy steels, and other ferrous materials. Additionally, non-ferrous metals like titanium, copper, and nickel-based alloys are also suitable for MIM. The metal powder used in the process is often finely ground to ensure proper flow and packing during injection molding. The choice of metal depends on factors such as the desired properties of the final part, its intended application, and cost considerations. Stainless steels are frequently used for their corrosion resistance, while tool steels are chosen for their hardness and wear resistance.

Generally, metal injection molding machines are a significant investment, and prices can range from hundreds of thousands to millions of dollars. The cost may also be influenced by additional factors such as the complexity of the machine’s design, automation features, and the level of precision and control it offers.