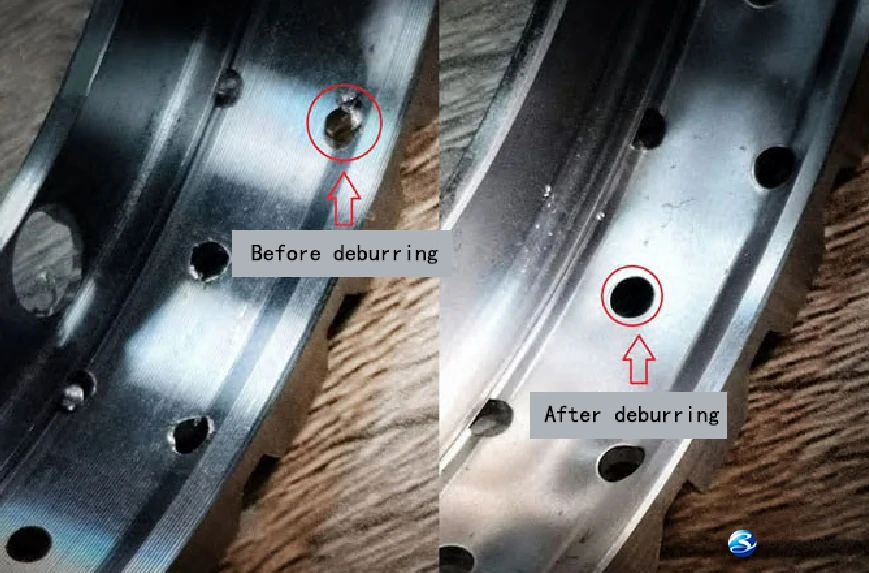

If you frequently purchase parts, you have likely encountered burrs on these parts and had to deal with the unwanted burrs on the parts. These defects can occur in various manufacturing processes such as drilling, milling, turning, grinding, or stamping, and if left untreated, they can compromise the functionality, safety, and aesthetics of the final product.

Therefore, deburring is a critical manufacturing process that involves the removal of unwanted burrs, sharp edges, or rough spots from a workpiece after it has been machined, cut, or formed. In this surface finishing guide, you will learn about the causes of burrs and how to remove them from parts.

What is Deburring And The Purpose Of Deburring?

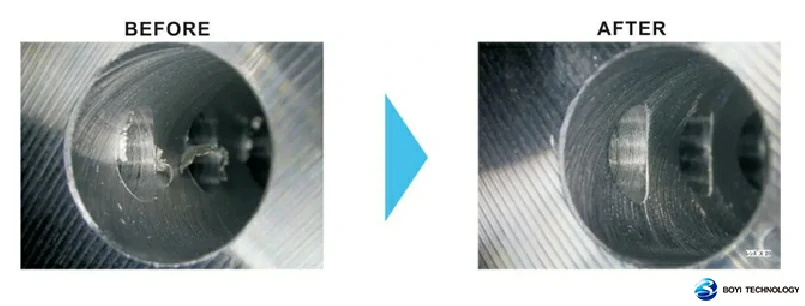

Deburring, in simple terms, is the process of removing small protrusions or sharp edges from parts. Why is this necessary? During the manufacturing process, parts may develop sharp edges or burrs due to cutting, grinding, or other operations. These burrs, though small, can pose significant hazards, affecting the performance of the part and potentially causing injury or damage to other equipment during use.

Therefore, the purpose of deburring is to make the parts smoother and more even, enhancing their quality and performance. This ensures that the parts operate smoothly and are less likely to malfunction. Additionally, removing burrs improves the aesthetic appearance of the parts, enhancing overall quality.

Imagine buying a new phone with rough edges that not only feel uncomfortable but also pose a risk of scratching your hands during use. In such cases, manufacturers need to deburr these edges to make the phone’s edges smooth and rounded.

Similarly, for mechanical parts, deburring is an essential step. Through deburring, we can ensure better quality and reliability of the parts, thereby improving the performance and reliability of the entire mechanical system.

10 Simple Deburring Processes and Methods

Deburring requires selecting different deburring methods and tools based on the material, shape, size, and characteristics of the parts. The following are some common deburring techniques:

1.Manual deburring

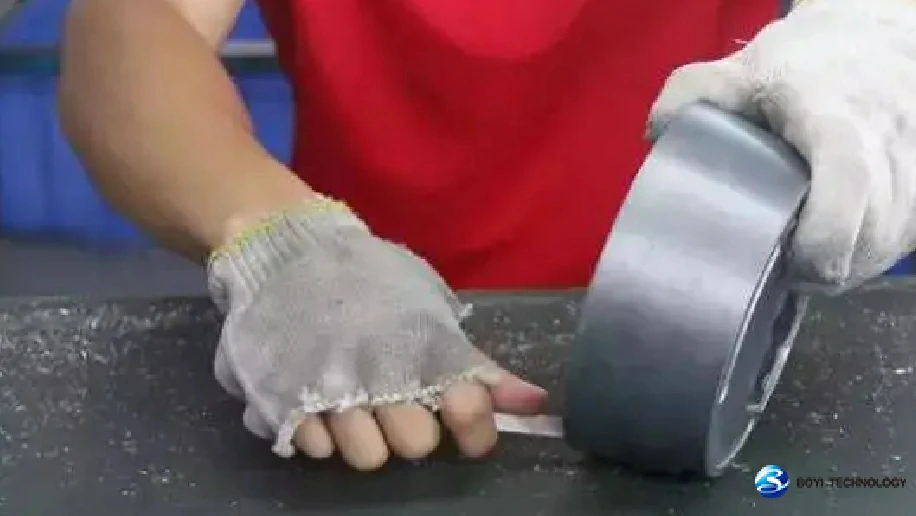

Manual deburring is one of the most traditional and common methods. This method relies on workers using hand tools such as sandpaper, files, or scrapers to finely process the surface of the product. Workers need to carefully inspect the product surface, identify and remove any unwanted burrs and edges to ensure a smooth and flawless surface.

When considering whether to use manual deburring, it’s essential to consider the actual situation and requirements of the product. If the quantity of products is small or the shapes are complex, manual deburring may be a more suitable choice.

- High cost: Hiring workers and paying labor costs is necessary.

- Low efficiency: Compared to automated methods, manual deburring is less efficient.

- Suitable for simple products: It is more suitable for products with fewer burrs and simple structures.

- Low technical requirements: Compared to other high-tech methods, manual deburring doesn’t require high technical skills from workers.

2.Punching die deburring

Punching die deburring is a widely used deburring technique in the manufacturing process. The core of this method lies in designing and producing specialized dies that can effectively remove burrs during product formation, greatly simplifying subsequent manual operations. Through punching die deburring, not only can production efficiency be improved and labor costs reduced, but product surface smoothness can also be ensured, enhancing product quality.

The advantages of punching die deburring lie in its efficiency and precision. Since the dies are custom-made according to the specific shape and size of the product, they can accurately remove burrs, avoiding damage to the product.

- Requires die fabrication: The cost of making dies may be relatively high.

- Suitable for simple products: Punching die deburring is an effective method for mass-producing simple products.

- High efficiency: Compared to manual deburring, punching die deburring is more efficient.

3.Grinding deburring

Grinding deburring is an efficient and commonly used deburring method that relies mainly on grinding tools such as grinding wheels, sandpaper, etc., to grind the surface of the product. By gradually removing surface irregularities and burrs, the product achieves a smooth finish.

This method is suitable for products made of various materials, whether metal, plastic, or others, can achieve a smooth surface through grinding deburring. At the same time, grinding deburring can also chamfer the edges and corners of the product, removing sharp edges, and improving product safety and aesthetics.

- Suitable for small products with large batches: Grinding deburring is a commonly used method for high volume production.

- May require subsequent manual processing: Grinding deburring may not completely remove burrs and may require manual processing of residual burrs.

4.Cryogenic deburring

Cryogenic deburring is a method that utilizes low-temperature environments to make materials brittle, thus facilitating the removal of burrs. During the cryogenic deburring process, the product is first placed in a low-temperature environment, such as by using liquid nitrogen for rapid cooling, which makes the burrs on the product’s surface brittle. Then, specialized tools such as pliers are used to gently tap or squeeze the product, causing the burrs to detach under external force.

This method is applicable to various materials, particularly products made of rubber and silicone. Because materials become brittle at low temperatures, deburring operations become easier without causing damage to the product itself. Additionally, cryogenic deburring can be finely tuned according to the shape and requirements of the product to ensure the removal of burrs while maintaining product integrity.

It is important to ensure uniform cooling of the product during cryogenic deburring to avoid stress concentration caused by temperature gradients. Moreover, selecting appropriate tools and methods is essential to avoid unnecessary damage to the product. Safety protocols should also be followed during operation to prevent frostbite from cold media such as liquid nitrogen.

- Suitable for situations with small burr thickness and small products: Cryogenic deburring is suitable for certain small-sized products, with better results for thin-walled burrs.

- High equipment costs: The equipment for cryogenic deburring may have a relatively high price.

5.Thermal deburring

Thermal deburring is a method used to remove surface burrs from products using a high-temperature heat source. The operation process mainly involves placing the product under a high-temperature heat source, such as using a flame or torch to heat the surface of the product, causing the burrs to reach a high-temperature state. Subsequently, the heated burrs are quickly dispersed or melted using airflow or other means, thereby achieving a smooth surface.

This method is relatively fast in deburring process due to the ability of high temperature to quickly soften or melt the burrs. Additionally, it is suitable for various materials, including metals, plastics, etc., and especially effective for hard burrs that are difficult to remove by other methods.

- Expensive equipment, high operational technical requirements: Thermal deburring equipment is expensive, and the operation requires high technical skills.

- Suitable for high-precision components: Primarily used in fields requiring high-precision deburring, such as automotive and aerospace industries.

Put your parts into production today

6.Engraving machine deburring

Engraving machine deburring is a method that utilizes CNC (Computer Numerical Control) technology to achieve precise deburring. Equipped with special tools, these tools are carefully designed to accurately handle the burrs and edges on the product surface. By programming the movement trajectory of the engraving machine’s tools, efficient deburring of the product surface can be achieved.

- Not very expensive equipment: Compared to some high-end technologies, the price of engraving machines is relatively low.

- Suitable for products with simple spatial structures: It is more suitable for products with simple structures and regular burr positions.

7.Chemical deburring

Chemical deburring is a method that utilizes chemical solvents or etchants to remove burrs from the surface of products. By immersing or coating the product in chemical solvents or etchants, they react chemically with the burrs, thereby dissolving or corroding the surface burrs. This method is typically used for products with specific material requirements or high surface treatment requirements.

It is important to note that the chemical solvents or etchants used in the chemical deburring process may pose certain risks to human health and the environment. Additionally, chemical deburring requires selecting and adjusting the types and concentrations of chemical solvents or etchants according to different materials and surface treatment requirements to ensure deburring effectiveness and product quality.

- Suitable for hard-to-remove internal burrs: Chemical deburring can effectively remove some internal burrs that are difficult to handle.

- Ideal for fine burrs: It works well for fine burrs.

8.Electrochemical deburring

Electrochemical deburring is an efficient and precise method for deburring, particularly suitable for metal products. The core principle of this method lies in utilizing electrolysis, whereby the product is placed in an electrolyte solution and an electric current is applied to remove surface burrs.

During the electrochemical deburring process, the product serves as either the anode or cathode, while the electrolyte solution provides the conducting medium. When the current passes through the electrolyte solution, it generates an electrolytic reaction on the product surface. This reaction gradually dissolves or removes the burr, achieving the purpose of deburring.

Electrochemical deburring can effectively remove burrs without damaging the product surface. Since the electrolytic action mainly focuses on the burr portion, the main surface structure of the product typically remains undamaged. This makes electrochemical deburring particularly suitable for metal products with high surface quality requirements.

- Efficient: Electrochemical deburring is fast and efficient.

- Attention to post-processing: Care must be taken regarding the impact of the electrolyte solution on the workpiece surface, requiring proper cleaning and rust prevention treatments.

9.High-pressure water jet deburring

High-pressure water jet deburring utilizes high-pressure water streams to impact the surface of the product, flushing away burrs and achieving deburring.

Compared to traditional mechanical deburring methods, high-pressure water jet deburring does not require the use of any chemicals, resulting in less environmental pollution. Additionally, because high-pressure water streams can adapt to different shapes and sizes of products, this method is highly versatile. It can achieve high-quality surface treatment for various materials, including metal, plastic, and glass. Moreover, this method can also be used to remove burrs from surfaces of materials such as rubber and ceramics.

In practical applications, high-pressure water jet deburring can be combined with other deburring methods to achieve better deburring results. For example, mechanical methods can be used first to remove the majority of burrs, followed by high-pressure water jet deburring for fine processing, further enhancing product quality and production efficiency.

- Expensive equipment: The equipment for high-pressure water jet deburring may have a high price.

- Suitable for specific areas: Primarily used for deburring specific areas in industries such as automotive and construction machinery.

10.Ultrasonic deburring

Ultrasonic deburring is particularly suitable for cases where high surface precision and sensitivity are required. During the ultrasonic deburring process, an ultrasonic generator produces high-frequency vibrations, which are converted into mechanical vibrations by a transducer and applied to the surface of the product.

The main advantages of this method lie in its non-contact and non-destructive nature. Since ultrasonic vibrations are transmitted through a medium, they do not cause mechanical damage or scratches to the product surface. This makes ultrasonic deburring an ideal choice for handling high-precision and sensitive surfaces.

Moreover, ultrasonic deburring can quickly remove burrs from various materials, including metals, plastics, ceramics, and more. Additionally, because the energy of ultrasonic vibrations can be focused on the burr area, precise deburring can be achieved, thereby improving product quality and consistency.

What Tool Is Used To Deburr?

There are various tools available for deburring, depending on the type of material and the size of the burr. Some common deburring tools include:

1.Manual Tools:

- File: This is a basic and common deburring tool available in various sizes and shapes. Files are suitable for manually removing burrs from small areas or complex-shaped workpieces. They offer flexibility in operation but relatively lower efficiency.

- Sandpaper and Abrasive Stones: These tools are often used for manual grinding and deburring. Sandpaper comes in different grit sizes to suit the material and deburring requirements. Abrasive stones can be used with power tools to enhance grinding efficiency.

2.Electric or Pneumatic Tools:

- Electric or Pneumatic Grinders: These tools use high-speed rotating grinding heads to remove burrs and are suitable for large areas and batch production. They typically offer high efficiency but may require some skill to operate.

- Dedicated Deburring Machines: Such as the Burr Remover by Tungsten Tool Works, these machines can directly remove burrs on surfaces without additional processing steps. They often feature high precision and efficiency, suitable for automated production lines.

3.Mechanical Deburring Tools:

- Roll Deburring Machines: These machines remove burrs by the relative movement between the workpiece and grinding blocks. They are suitable for batch processing and can efficiently remove burrs from a large number of workpieces.

- Brush Deburring Machines: These machines use specialized brushes for grinding and deburring workpieces. Brushes can be customized according to the shape and material of the workpiece, suitable for various complex-shaped workpieces.

4.Chemical or Electrolytic Methods:

- Chemical Deburring: This method uses specific chemical solvents or etchants to dissolve or corrode burrs on the surface. It is suitable for certain types of materials but requires attention to environmental and operator safety.

- Electrolytic Deburring: This method uses electrolysis to remove burrs from metal parts. It offers high precision and efficiency but may require specialized equipment and operating techniques.

5.Other Specialized Tools:

- Punching Dies: Used in conjunction with punch presses, these tools can quickly remove burrs from products with relatively simple parting surfaces. However, the design and manufacturing of punching dies need to be customized according to specific products.

- Engraving Machines: Suitable for removing burrs from workpieces with simple spatial structures and regular positions. By programming the movement trajectory of the tool, precise deburring operations can be achieved.

Which Type Of Deburring Tool Is More Effective?

The choice of deburring tool largely depends on specific application scenarios, material of the workpiece, shape, size, and precision requirements for deburring.

For example, manual tools such as files and sandpaper, while simple to operate, have lower efficiency and are suitable for small batch production and repair work. Electric or pneumatic tools such as grinders offer higher efficiency and are suitable for large areas and batch production of workpieces. Mechanical deburring tools such as roll deburring machines and brush deburring machines can achieve automated and semi-automated deburring operations, thereby improving production efficiency.

Furthermore, there are specialized deburring tools such as punching dies, engraving machines, cryogenic deburring machines, and thermal deburring machines, each suitable for specific deburring needs. For instance, punching dies are suitable for removing burrs from products with relatively simple parting surfaces, engraving machines are suitable for removing burrs from workpieces with simple and regular spatial structures, while cryogenic deburring machines and thermal deburring machines are suitable for some special materials or workpieces with high precision requirements.

When selecting a deburring tool, there is no universally applicable “best” tool. The choice of deburring tool should be based on a careful consideration of specific needs and conditions.

How To Prevent The Formation of Burrs?

To avoid the generation of burrs, the following measures can be taken:

- Utilize precision machining techniques: Precision machining can reduce the formation of burrs. For example, employ precision cutting processes, electrical discharge machining, or laser cutting for high-precision machining.

- Use specialized tools and equipment: Choose high-quality tools and equipment, such as high-speed steel tools, carbide tools, or drills, to ensure smooth cutting surfaces during machining and reduce the generation of burrs.

- Implement precise machining parameters: Adjust machining parameters such as cutting speed, feed rate, and cutting depth according to the type of material and machining requirements to ensure smooth processing and reduce the generation of burrs.

- Regularly maintain and replace tools: Regularly inspect, sharpen, and replace tools to maintain their sharpness and machining efficiency, reducing the generation of burrs due to tool wear.

- Utilize specialized surface treatment methods: After machining, professional surface treatment methods such as chemical polishing, electrochemical polishing, or magnetic polishing can be used to remove residual burrs and improve surface quality.

- Strictly control the machining environment: Ensure the machining environment is clean and tidy, and control vibrations and temperature changes during the machining process to reduce the generation of burrs.

Conclusion

Choosing the right method for deburring is crucial to ensure that you do not cause further damage to your parts, while also avoiding wasting time and cost. Proper deburring, if done correctly, can help you achieve the smooth, flawless finish required for machined parts. However, it’s also important to know when deburring is not necessary, as this can save you both cost and time.

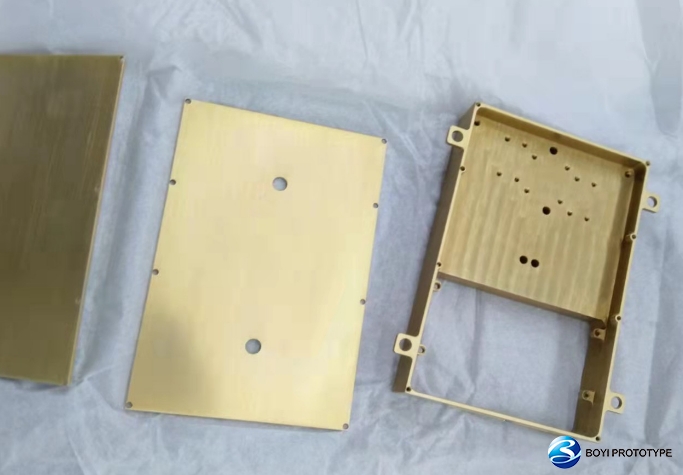

BOYI Precision Machining Services

We can provide customized precision machining services according to your needs, including tolerances, materials, and surface finish. And ensure that the parts are carefully processed without leaving any burrs, presenting a professionally processed appearance. If you have any other questions or need further information about our services, please feel free to contact us at any time.

Put your parts into production today

FAQ

To deburr metal, common methods include manual tools like files and abrasive stones, mechanical options such as deburring machines, and specialized techniques like thermal or electrochemical deburring.

A major problem with mechanical hand deburring is inconsistency in results due to variations in operator technique, which can lead to uneven deburring and potential damage to the metal surface.

Deburring removes burrs and rough edges for safety and functionality, while polishing enhances the appearance and surface finish of metal parts.